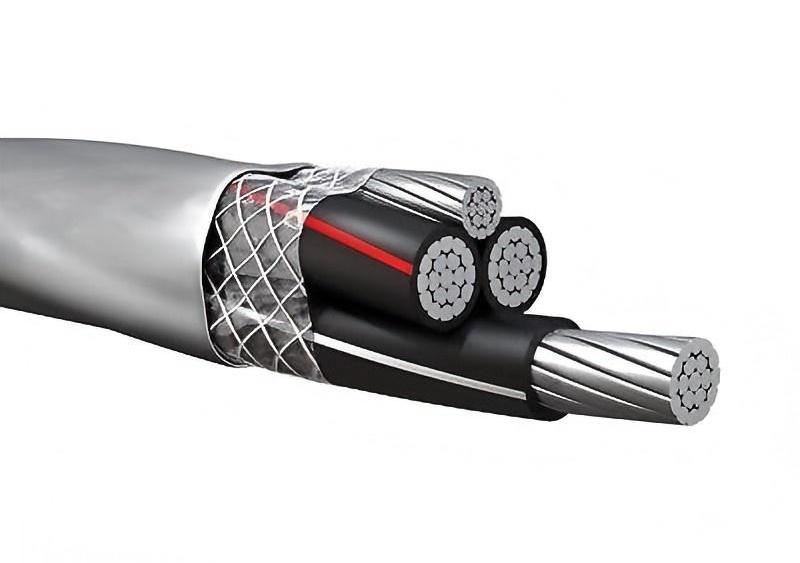

Aluminum cable wire, a power transmission medium made from aluminum alloys, is becoming increasingly prevalent in various industries. Known for its low density, excellent conductivity, and corrosion resistance, aluminum cable wire presents several advantages over traditional copper cables. It is particularly valued in applications where weight reduction, cost savings, and environmental impact are key considerations. This article explores the key performance characteristics of aluminum cable wire and its diverse applications, with a special focus on its role in renewable energy sectors such as photovoltaic (PV) systems, wind power, and electric vehicle (EV) charging infrastructure.

Key Performance Characteristics of Aluminum Cable Wire

1. Electrical Conductivity

One of the primary considerations for any electrical cable is its conductivity. While aluminum cable wire’s electrical conductivity is lower than that of copper, it has been optimized through various technological advancements to meet most power transmission needs effectively. Aluminum has about 60% of the conductivity of copper, but this can be compensated by increasing the cable’s cross-sectional area. Advances in alloy technology and cable design have further enhanced the performance of aluminum wires, making them suitable for many high-demand applications.

2. Good Creep Resistance

Creep resistance refers to the ability of a material to resist deformation under prolonged stress. Aluminum cable wire exhibits strong creep resistance, which is crucial for maintaining cable integrity in fluctuating temperatures. The material’s ability to withstand thermal expansion and contraction helps prevent slack and maintains consistent performance over time. This is particularly important in applications where cables are exposed to varying temperatures or mechanical stresses.

3. Superior Corrosion Resistance

Corrosion resistance is another critical property of aluminum cable wire. Compared to pure aluminum, aluminum alloys used in cable manufacturing offer superior resistance to corrosion, especially in environments with sulfur compounds. This makes aluminum cables particularly suitable for applications in harsh or outdoor environments where exposure to moisture and corrosive elements is common. In fact, aluminum cables are often preferred in coastal regions or industrial settings due to their durability against corrosive agents.

4. Mechanical Properties

Aluminum cable wire combines high tensile strength and elongation properties with excellent bending flexibility. This means that aluminum cables can endure significant mechanical stress without losing their performance. Their flexibility and strength make them easier to handle, install, and maintain compared to more rigid materials. The combination of these mechanical properties ensures that aluminum cables perform reliably in various installation scenarios and operational conditions.

Aluminum Cable Wire in Renewable Energy

1. Photovoltaic (PV) Systems

Aluminum cable wire is essential in photovoltaic (PV) systems, where it connects solar panels to inverters and transmits electricity to the grid. Its lightweight and flexible nature simplifies installation and handling, making it ideal for outdoor environments. Aluminum’s resistance to corrosion ensures that these cables can withstand exposure to weather conditions, extending their lifespan and maintaining reliability.

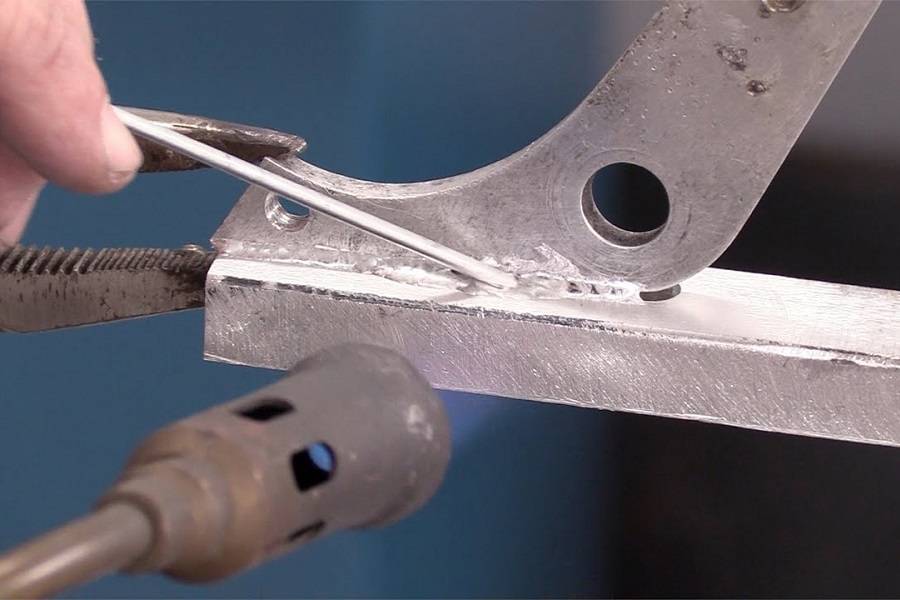

Integration of Aluminum Cable Wire in PV Systems

- Connecting Solar Panels: Aluminum cables link individual solar panels or arrays, providing flexibility to adapt to various installation angles and positions. Connectors at the cable ends facilitate quick and secure attachment to the panels’ junction boxes.

- Series and Parallel Configurations: These cables are used to connect panels in series or parallel, leading to a combiner box or directly to an inverter. This setup consolidates power generated by multiple panels or arrays.

- Inverter Connection: Power collected from the panels is transmitted to an inverter via aluminum cables. The inverter converts direct current (DC) into alternating current (AC) for grid integration or use in homes and businesses. The cables must handle higher voltage and current while remaining flexible and durable.

- System Design: The design of the PV system considers cable length, bending radius, environmental factors, and mechanical stress. Proper selection and layout of aluminum cables are crucial for minimizing energy loss and ensuring system efficiency and stability.

2. Wind Power Systems

In wind power applications, aluminum cable wire is particularly suited for long-distance transmission from wind turbines to the grid. The cable’s high conductivity and lightweight properties make it ideal for remote locations, while its corrosion resistance ensures durability in harsh environmental conditions.

Benefits of Aluminum Cable Wire for Wind Power Transmission

- Weight Reduction: The lightweight nature of aluminum reduces the overall weight of transmission lines, lowering the costs of support structures and foundations.

- Optimized Conductivity: While aluminum’s conductivity is less than copper’s, advances in alloy technology and cable design have improved its performance, making it effective for long-distance transmission.

- Enhanced Strength and Durability: Aluminum cables offer greater mechanical strength and creep resistance compared to pure aluminum, ensuring they can withstand external pressures such as wind loads.

- Corrosion Resistance: Aluminum cables are well-suited for coastal or sandy environments, where their resistance to corrosion minimizes maintenance and extends service life.

- Cost Efficiency: The lower cost of aluminum relative to copper makes it a cost-effective option for large-scale wind power projects, helping to reduce overall investment and operational expenses.

- Ease of Installation: The flexibility and light weight of aluminum cables facilitate easier installation and maintenance, enhancing their suitability for wind power applications.

3. Electric Vehicle (EV) Charging Infrastructure

Aluminum cable wire offers several advantages in EV charging infrastructure, contributing to the growth of electric vehicle technology. Its lightweight design and cost efficiency are particularly beneficial for the development of widespread charging solutions.

Advantages of Aluminum Cable Wire for EV Charging

- Reduced Weight: The low density of aluminum helps decrease the overall weight of charging equipment, which can improve energy efficiency and vehicle range.

- Cost Savings: Aluminum’s lower material cost helps reduce the production costs of charging stations, making them more affordable for widespread deployment.

- Efficient Electrical Performance: By adjusting the wire gauge, aluminum cables can meet the electrical resistance requirements for EV charging, ensuring effective power transfer.

- Thermal Management: Aluminum’s high thermal conductivity aids in heat dissipation during charging, improving safety and efficiency.

- Resource Abundance: The plentiful availability of aluminum, especially in regions like China, helps stabilize material costs and supply chains.

- Environmental Benefits: Aluminum’s recyclability supports the sustainability goals of the EV industry, aligning with eco-friendly practices and reducing environmental impact.

Aluminum cable wire offers numerous advantages that make it a compelling choice for various applications, particularly in renewable energy sectors. Its key performance characteristics, such as electrical conductivity, creep resistance, corrosion resistance, and mechanical properties, ensure reliable and efficient operation in diverse environments. The benefits of aluminum cables in photovoltaic systems, wind power, and electric vehicle charging infrastructure underscore their role in advancing energy efficiency and sustainability. As technology continues to evolve and market demands grow, aluminum cable wire is poised to play an increasingly important role in shaping the future of energy transmission and infrastructure.

If you’re considering aluminum cable wire for your projects, CHAL offers high-quality solutions tailored to meet your needs. Contact CHAL to discuss how their aluminum cable wire can enhance your projects and meet your specific requirements.