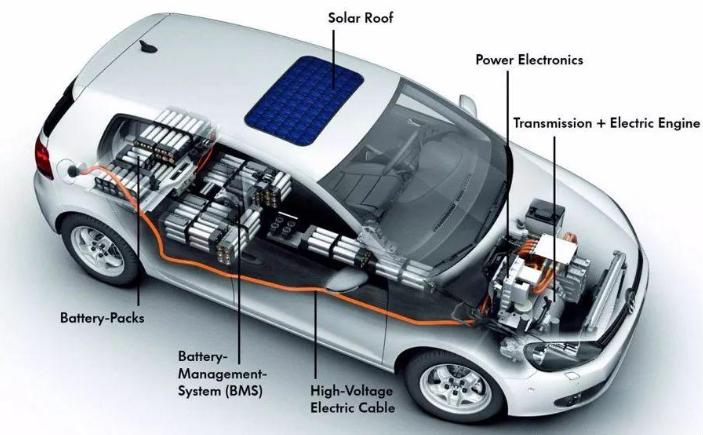

High-pressure gas cylinders are indispensable in various industries, ranging from medical and industrial applications to recreational activities like scuba diving. Among the many materials used for cylinder construction, aluminum has gained significant popularity due to its unique properties. However, a crucial question remains: Are aluminum high-pressure gas cylinders safe?

Here we explore the safety features of aluminum gas cylinders, factors that influence their safety, and how they compare to cylinders made of other materials. By the end, you’ll understand why aluminum cylinders are a reliable choice for high-pressure gas storage.

Safety Features of Aluminum High-Pressure Gas Cylinders

Aluminum cylinders are specifically designed to meet stringent safety requirements, ensuring their reliability in high-pressure environments. Their properties and manufacturing processes contribute significantly to their safety performance. Some key safety features including:

- Durable Material Composition: Aluminum alloys used in cylinder construction are strong and resistant to deformation, allowing them to withstand high pressures safely.

- Corrosion Resistance: Unlike steel, aluminum does not rust, even in humid or marine environments, reducing the risk of material degradation and failure over time.

- Lightweight Design: The lighter weight of aluminum cylinders makes them easier to handle and reduces the chances of accidents during transport and use.

- Rigorous Testing and Certification: Aluminum cylinders undergo hydrostatic testing, visual inspections, and other safety checks during manufacturing. They are certified to meet international safety standards like DOT (Department of Transportation) and ISO (International Organization for Standardization).

- Thermal Properties: Aluminum dissipates heat quickly, reducing the risk of explosion or rupture due to thermal expansion when exposed to high temperatures.

The combination of strength, corrosion resistance, and advanced safety testing ensures that aluminum high-pressure gas cylinders are a reliable and safe option for various applications.

Factors Affecting the Safety of Aluminum High-Pressure Gas Cylinders

While aluminum cylinders are inherently safe, their performance can be influenced by external factors. Understanding these factors is key to maintaining their safety in practical use. The key factors including:

1. Production process

The heat treatment process is crucial. If there is a problem in the heat treatment process during production and processing, such as the heating time is too long or the temperature is too high, the gas cylinder will be overburned. This will cause the material of the gas cylinder to become hard and brittle, greatly increasing the risk of explosion, and may produce fragments instead of normal tearing mode when it explodes.

Quality control in the manufacturing process should not be ignored. For example, the uniformity of the wall thickness of the gas cylinder and the processing accuracy of the bottle mouth thread will affect its safety. If the wall thickness is uneven, the thinner parts are prone to damage first when subjected to high pressure; the processing accuracy of the bottle mouth thread is not enough, which may lead to poor sealing and cause safety hazards such as gas leakage.

2. Use conditions

The inflation pressure must be strictly controlled. If the inflation pressure exceeds the limit that the aluminum gas cylinder can withstand, it will cause irreversible damage to the structure of the gas cylinder, especially the neck of the gas cylinder may be over-expanded, which is a very dangerous situation.

The frequency of use and the rest cycle are also closely related to safety. If the gas cylinder is used continuously for a long time without enough rest time for natural cooling, heat accumulation will occur, resulting in cracks in the shoulder and other parts, which will affect the safety of the gas cylinder.

The use environment will also affect safety. High temperature environment may reduce the strength of gas cylinder materials, high humidity environment may accelerate the corrosion of gas cylinders, and severe vibration may cause damage to the internal structure of gas cylinders or external collision damage.

3. Maintenance

Regular inspection is an important means to ensure the safety of gas cylinders. Users need to conduct an appearance inspection of gas cylinders to check whether there are corrosion, deformation, cracks, etc., and also conduct pressure tests to ensure that the gas cylinders can be used safely within the specified pressure range.

Maintenance work must be in place. This includes regular cleaning of the surface of gas cylinders to prevent impurities from corroding gas cylinders; timely replacement of seals in accordance with regulations to ensure the sealing of gas cylinders, etc.

Factors such as production process, use conditions and maintenance have a profound impact on the safety of aluminum high-pressure gas cylinders. Problems in any link may lead to safety hazards, so relevant standards and regulations must be strictly observed in each link to ensure the safe use of aluminum high-pressure gas cylinders.

Comparison with Other Material Cylinders

Gas cylinders can be made from various materials, including steel, composites, and aluminum. Each material has its advantages and limitations, especially when it comes to safety.

| Feature | Aluminum Cylinders | Steel Cylinders | Composite Cylinders |

| Weight | Lightweight, easy to handle, reducing transport risks. | Heavy, increasing strain during handling and use. | Extremely lightweight but less impact-resistant. |

| Corrosion Resistance | Naturally resistant to rust, ideal for humid or marine use. | Prone to rust without protective coatings. | Non-corrosive but can degrade with UV exposure. |

| Durability | Strong and impact-resistant, with excellent material integrity. | Highly durable but can degrade if corroded. | High strength-to-weight ratio but less impact-resistant. |

| Thermal Properties | Dissipates heat efficiently, reducing risks of thermal expansion. | Retains heat longer, increasing thermal stress. | Poor heat resistance, not suitable for high-temperature applications. |

| Maintenance | Requires minimal maintenance due to corrosion resistance. | Needs regular upkeep to prevent rust and wear. | Requires careful handling to avoid physical or UV damage. |

| Applications | Versatile for medical, industrial, and recreational uses. | Common in industrial applications requiring durability. | Preferred in portable applications like SCBA tanks. |

| Cost | Moderate cost, balancing affordability and performance. | Lower initial cost but higher long-term maintenance. | Higher upfront cost but lightweight benefits. |

While steel and composites have their merits, aluminum strikes a balance between strength, corrosion resistance, and weight, making it a safer and more versatile option for high-pressure gas cylinders.

Summary

Aluminum high-pressure gas cylinders are a safe and reliable choice for gas storage across a variety of applications. Their inherent material properties, such as corrosion resistance, lightweight design, and strength, contribute to their safety and ease of use. Additionally, rigorous manufacturing standards and proper maintenance practices ensure their long-term reliability.

Compared to other materials, aluminum cylinders offer a superior combination of safety, durability, and practicality. However, users must adhere to recommended guidelines for usage, storage, and inspections to maintain their safety.

In conclusion, when used correctly, aluminum high-pressure gas cylinders are a dependable solution for industries and individuals requiring secure and efficient gas storage.