In the realm of electrical wiring, two commonly used materials are bare aluminum wire and bare copper wire. Both play crucial roles in various applications, but it is important to understand their differences and compare their performance characteristics. This article aims to provide a comprehensive analysis of bare aluminum wire and bare copper wire, focusing on factors such as electrical conductivity, corrosion resistance, cost, weight, and flexibility.

Electrical Conductivity of Bare Aluminum Wire and Bare Copper Wire

When it comes to electrical conductivity, bare copper wire has long been considered the standard. Copper exhibits excellent conductivity properties, allowing for efficient transmission of electrical current. It boasts a high electrical conductivity rating, making it suitable for applications where low resistance and minimal power loss are paramount.

On the other hand, bare aluminum wire has slightly lower conductivity compared to copper. Although aluminum does not match copper’s conductivity, advancements in aluminum alloys have significantly improved its performance. Aluminum wire can still deliver adequate conductivity in various applications, especially when properly sized and installed.

Corrosion Resistance of Bare Aluminum Wire and Bare Copper Wire

Corrosion resistance is a critical factor to consider when selecting wiring materials, particularly in environments where moisture, humidity, and other corrosive elements are present. Bare aluminum wire is inherently more susceptible to corrosion than bare copper wire. Aluminum readily oxidizes, forming a thin layer of aluminum oxide on its surface, which can hinder conductivity over time. However, protective measures such as special coatings or using aluminum alloys with enhanced corrosion resistance can mitigate this issue.

In contrast, bare copper wire is known for its excellent corrosion resistance. Copper’s natural patina, which develops over time, acts as a protective layer, safeguarding the wire against corrosion. Nevertheless, in particularly corrosive environments, additional coatings or treatments may be necessary to ensure optimal performance.

Cost of Bare Aluminum Wire and Bare Copper Wire

Cost is a significant consideration in any electrical project. Bare aluminum wire is generally more cost-effective than bare copper wire. Aluminum is more abundant and less expensive than copper as a raw material, leading to lower manufacturing costs. Additionally, aluminum wire is lighter, reducing transportation costs. For budget-conscious projects, aluminum wire can provide a cost-efficient alternative without compromising performance.

Weight and Flexibility of Bare Aluminum Wire and Bare Copper Wire

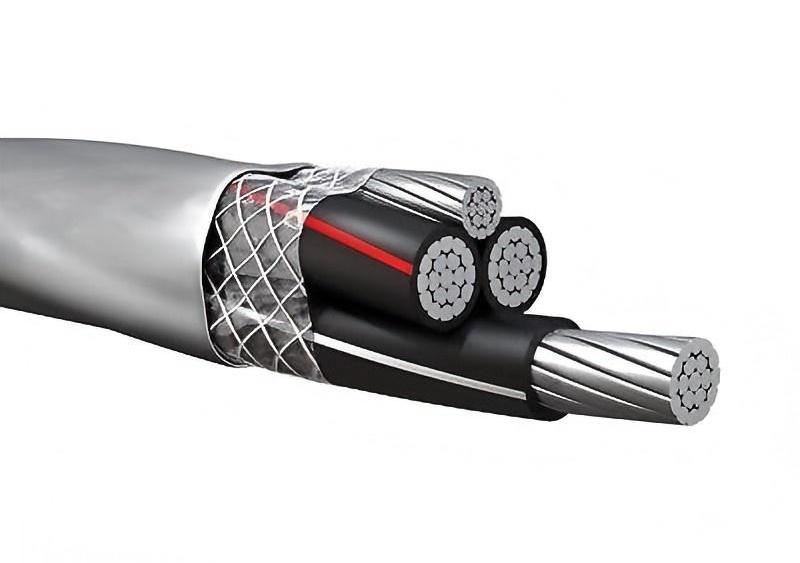

The weight and flexibility of wiring materials can impact installation and overall project feasibility. Bare aluminum wire is significantly lighter than bare copper wire. This characteristic makes it easier to handle during installation, reduces strain on supporting structures, and lowers shipping costs. Additionally, aluminum’s malleability enhances its flexibility, making it suitable for applications that require bending and shaping.

Bare copper wire, while heavier than aluminum wire, still offers manageable flexibility. Its weight can provide stability and durability in certain installations where mechanical strength is essential. However, for applications that require extensive maneuverability and flexibility, the lighter weight of aluminum wire may be advantageous.

Summary and Conclusion

In conclusion, bare aluminum wire and bare copper wire each possess unique characteristics that make them suitable for different electrical applications. Copper wire has long been favored for its high electrical conductivity and excellent corrosion resistance. On the other hand, aluminum wire offers cost savings, reasonable conductivity, and weight advantages. It is important to consider the specific requirements of a project and the environment in which the wiring will be installed.

For projects where cost-effectiveness and weight are crucial, bare aluminum wire can provide a viable solution without compromising performance. However, in applications where conductivity and corrosion resistance are paramount, bare copper wire remains the preferred choice. Additionally, advancements in aluminum alloys and protective coatings have made aluminum wire more reliable and corrosion-resistant.

As technology continues to evolve, new materials and alternatives may emerge, providing even more options for electrical wiring. Regardless of the material chosen, it is essential to adhere to industry standards, proper installation techniques, and regular maintenance to ensure the longevity and safety of electrical systems.