As an excellent packaging material, aluminum foil is widely used for packaging food, household daily necessities, and medicines. Aluminum foil is a soft metal film, which not only has the advantages of moisture-proof, air-tight, shading, abrasion resistance, fragrance retention, non-toxic and tasteless, etc., but also because of its elegant silver-white luster, it is easy to process beautiful patterns and various colors. Patterns are more likely to be favored by people. This article is to let everyone know some little knowledge about aluminum foil that is not well known. Help you to more accurately choose the aluminum foil products that suit you.

The particularity of aluminum foil rolling

In the production of double foil, the rolling of aluminum foil is divided into three processes: rough rolling, intermediate rolling, and finishing rolling. From a technological point of view, it can be roughly divided by the thickness of the rolling exit. The general method is that the exit thickness is greater than Or equal to 0.05mm in rough rolling, the exit thickness is between 0.013 and 0.05 is intermediate rolling, and the single finished product and the double rolled product with the exit thickness less than 0.013mm are finished rolling. The characteristics of rough rolling are similar to the rolling characteristics of aluminum plates and strips. The thickness control mainly depends on the rolling force and post-tension. The thickness of the rough rolling is very small, and its rolling characteristics are completely different from the rolling of aluminum plates and strips. It has aluminum foil rolling.

The particularity of, its characteristics mainly include the following aspects:

Plate Aluminum Strip Rolling

To make the aluminum strip thinner mainly depends on the rolling force, so the automatic plate thickness control method is the constant roll gap as the main control method of the AGC. Even if the rolling force changes, the roll gap can be adjusted at any time to keep the roll gap at a certain value to obtain the thickness Consistent plate and strip.

The finishing process of aluminum foil rolling inside refers to the fact that the thickness of the aluminum foil is extremely thin. During rolling, the rolling force is increased, which makes the roll elastic deformation easier than the plastic deformation of the rolled material. The elastic flattening of the rolls cannot be ignored. The elastic flattening of the rolls determines that in the aluminum foil rolling, the rolling force can no longer play the same role as the rolled plate. Aluminum foil rolling is generally rolled less under constant pressure conditions. For seam rolling, adjusting the thickness of the aluminum foil mainly depends on the adjusted tension and rolling speed.

Stack Rolling

For ultra-thin aluminum foil with a thickness of less than 0.012mm (the thickness is related to the diameter of the work roll), it is very difficult to use the elastic flattening of the rolls and the single-sheet rolling method, so the double rolling method is adopted. That is, the method of adding lubricating oil between the two aluminum foils and then rolling them together (also called stack rolling). Stack rolling can not only produce ultra-thin aluminum foil that cannot be produced by single rolling but also reduces the number of strip breaks and increase labor productivity. Using this process, single-sided smooth aluminum foil of 0.006mm to 0.03mm can be mass-produced.

Speed Effect

In the process of aluminum foil rolling, the phenomenon that the thickness of the foil thins with the rise of the rolling system is called the speed effect. The explanation of the speed effect mechanism still needs to be studied in depth. The reasons for the speed effect are generally considered to have the following three aspects:

The friction state between the work roll and the rolled material changes. As the rolling speed increases, the amount of lubricating oil introduced increases, so that the lubrication state between the roll and the rolled material changes. The friction coefficient decreases, the oil film becomes thicker, and the thickness of the aluminum foil decreases accordingly.

Changes in the rolling mill itself. In a rolling mill with cylindrical bearings, as the rolling speed increases, the roll neck will float in the bearing, causing the two interacting rolls to approach each other.

The material is softened by processing when it is deformed by rolling. The rolling speed of the high-speed aluminum foil rolling mill is very high. As the rolling speed increases, the temperature of the rolling deformation zone increases. According to statistics, the metal temperature in the deformation zone can rise to 200°C, which is equivalent to an intermediate process in the process. Annealing, thus causing the processing softening of the rolled material.

The thickness measurement methods of aluminum foil rolling mainly include eddying current thickness measurement, isotope ray thickness measurement, and X-ray thickness measurement. X-ray thickness measurement is the most common method used in aluminum foil production, especially in high-speed aluminum foil rolling mills. Thickness control methods during aluminum foil rolling: rolling force control, tension control, rolling speed control, tension/speed, speed/tension control.

Aluminum foil also needs anti-corrosion

The main reason for the corrosion of aluminum foil is that the product is damp or exposed to water during the production process and the circulation process. Therefore, in order to avoid the production of corrosive waste, it is mainly to prevent the aluminum foil from contacting water. Anti-corrosion measures:

①Add an air dryer to ensure that there is no moisture in the compressed air.

②Strengthen the management of rolling oil and control its water content below 400×0.000001.

③The packaging of aluminum foil rolls should be sealed, and each roll should be put in an appropriate amount of desiccant.

④The humidity of the wooden shaft and the box board of the packaging box is not more than 18%, and the temperature of the packaging aluminum coil is not more than 45 degrees Celsius.

⑤Do not open the sealed package immediately when transporting from the low-temperature area to the area with high temperature and high humidity.

⑥Aluminum foil rolls should not be placed on the roofs of workshops and warehouses where there is rain or snow leakage.

⑦When transporting aluminum foil from a low-temperature area to a high-temperature area, the sealing of the package should be strengthened, and a desiccant should be added when necessary.

⑧When packaging aluminum foil products in the rainy season, seal packaging should be strengthened and desiccant should be added.

Different packaging requires different aluminum foils

Technology is constantly improving and updating. With the continuous update of production technology, the manufacturing process of aluminum foil is also continuously optimized. Now the market has produced aluminum foil materials that specifically serve various products according to different packaging needs. Now I will focus on introducing several aluminum foil products that have the best sales share in the international market in recent years.

Air Conditioner Foil

Air conditioner foil is a special material for manufacturing heat exchanger fins for air conditioners. The air conditioner foil used in the early days is plain foil. In order to improve the surface performance of the plain foil, an anticorrosive inorganic coating and a hydrophilic organic coating are applied before forming to form a hydrophilic foil. Hydrophilic foil accounts for 50% of the total air conditioning foil, but its use ratio will be further increased. In addition, there is a kind of water-repellent foil, which makes the surface of the fins have a water-repellent function to prevent the adhesion of condensed water. As the technology of hydrophobic foil to improve the surface defrosting property needs further research, the actual product is very few.

Generally, the thickness of air conditioner foil is 0.1mm~0.15mm. With the development of technology, there is a trend of further thinning of air-conditioning foils. Japan’s leading product has a thickness of 0.09mm. In an extremely thin state, aluminum foil must have good formability, its structure and properties must be uniform, metallurgical defects are small, anisotropy is small, and it requires high strength, good ductility, uniform thickness, and good flatness. The specifications and alloys of air-conditioning foil are relatively simple and suitable for large-scale production. However, the market is highly seasonal. For professional manufacturers of air-conditioning foils, it is difficult to solve the contradiction between demand in peak season and almost no demand in the off-season.

Decorative Foil

Decorative foil is a decorative material applied in the form of aluminum-plastic composite, which makes use of aluminum foil’s good colorability and high light and heat reflectivity. It is mainly used for decoration of buildings and furniture and as part of gift box packaging. Decorative foil has the advantages of heat insulation, moisture resistance, sound insulation, fire prevention, and easy cleaning, etc., and it has a luxurious appearance, convenient processing, and fast construction and installation speed.

Cable Foil

The cable foil is an aluminum-plastic composite foil formed by using the airtightness and shielding properties of the aluminum foil, coated with a plastic film on one or both sides, and used as a cable shield. The cable foil requires less oil on the surface, no holes, and high mechanical properties. The overall quality requirements are not high, but the length requirements are extremely strict.

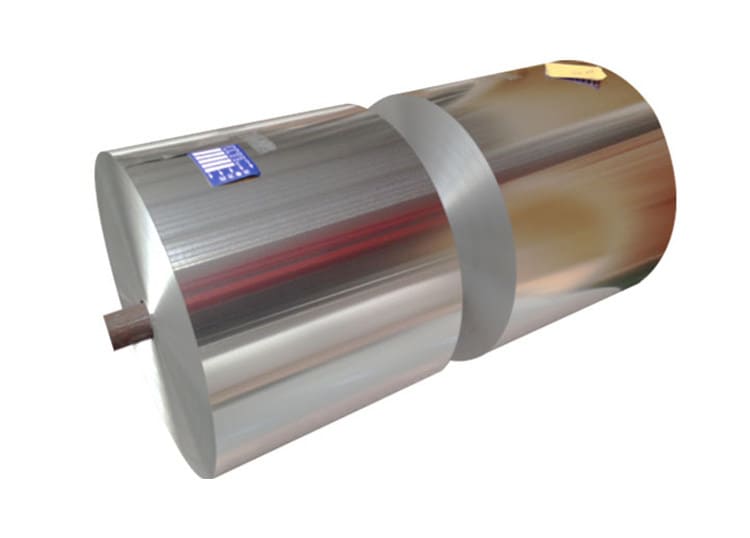

Choose the best aluminum foil supplier

There are many aluminum foil suppliers and many aluminum foil products on the market. How to choose the best aluminum foil supplier? This becomes a very important issue. I recommend CHAL Aluminium Corporation to you. As an established aluminum foil supplier, CHAL has a complete range of aluminum foil products. Its products include: 3003 Aluminum Foil, 3004 Aluminum Foil, Battery Aluminium Foil, Aluminium Foil For Air Conditioner and so on.

Aluminium Foil For Air Conditioner

CHAL can not only provide all kinds of aluminum foil products, but also provide customized aluminum foil services. If you need high-quality aluminum foil products, you can contact us and we will do our best to serve you.