Aluminum is an amazing material that has impacted nearly every major industry over the past century. This includes the medical industry and the many devices we know are transforming healthcare. Today, we’ll look at aluminum alloys and aluminum profiles commonly found in the medical industry, and why they offer so many advantages.

Medical care is an industry that has very little margin for error. Lives are literally at stake. For any material to be deemed fit for medical devices, it must meet very high standards of performance and reliability. A factor not always considered in other industries is that medical devices, tools, and equipment must have very high sanitation levels. This is an area where aluminum particularly excels.

If you work in the medical industry or are manufacturing products intended for medical use, you need to be sure that any aluminum you source is of the highest quality. That’s why it always pays to work with a trusted supplier with a proven track record of success.

What are the advantages of aluminum?

Many of the same benefits that make aluminum so popular in modern industries such as construction, aerospace, and technology also apply to the medical industry. Most notably, aluminum is very light and has one of the best strength-to-weight ratios of any metal. This means that devices made of aluminum can be thin, light, flexible, and still very strong and durable. Few other materials can match aluminum in this regard.

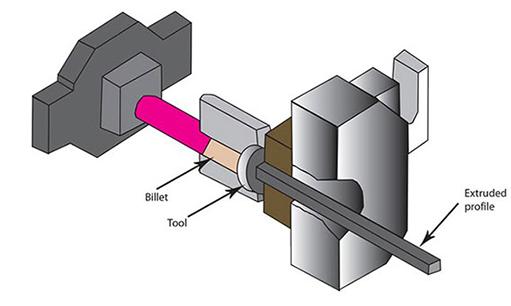

Another advantage of aluminum is its formability. Devices made of aluminum can be easily fabricated into any desired form, making it useful for medical devices that must be fabricated to precise specifications. This is especially true for therapeutic and prosthetic devices and devices tailored to the patient. Aluminum offers exceptional design flexibility, helping to enable modern advancements in medical devices.

Where can we find aluminum alloys in the medical field?

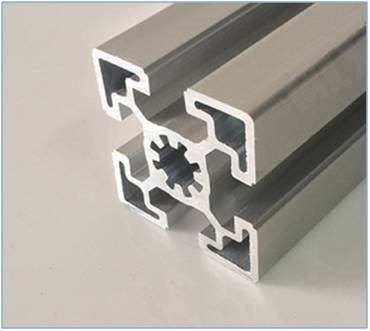

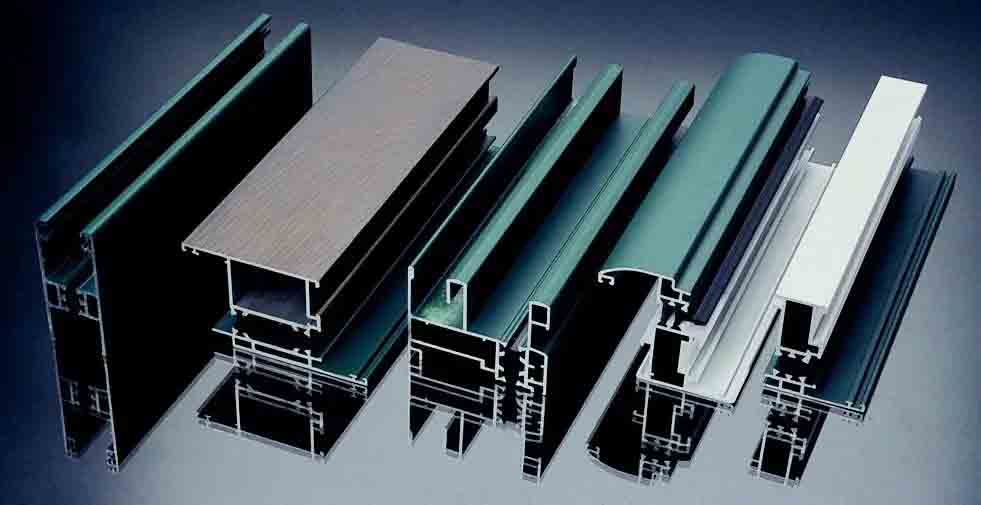

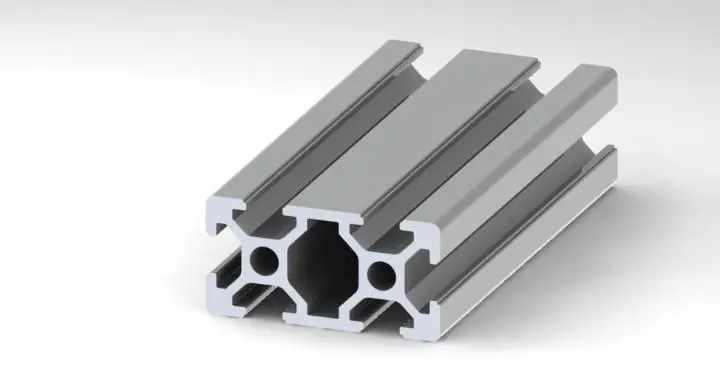

In the medical field, aluminum alloys are most often found in the form of aluminum profiles. Because aluminum profiles have a series of excellent properties, they are favored by the medical and health field, and their dosage is also increasing, and their applications are becoming more and more extensive.

Among them, aluminum alloy medical equipment is the most widely used field of aluminum alloy. Aluminum alloy medical equipment refers to the instruments, equipment, appliances and calibration objects, materials, and other similar or related items that are directly or indirectly used in the human body using aluminum alloys as materials.

Since the 21st century, many new technologies and products have appeared in the aluminum alloy medical device industry, which has greatly improved and improved clinical medicine. The future of aluminum alloy medical devices must be combined with information technology, nanotechnology, and biological science.

The main use of aluminum profiles in the medical field

(1) Ambulance and nursing equipment and facilities. Aluminum profiles are widely used in special ambulances, special medicine vehicles, and internal facilities. They are over 30% aluminum; most stretchers, beds, crutches, armrests, prosthetics, and rocking chairs are aluminum plated.

(2) Health, fitness, and assistive devices and equipment. Glasses frames, hearing aids, other auxiliary treatment devices and treadmills, and other fitness equipment are mostly aluminum-plated.

(3) Medical devices and instruments. A wide range of medical devices and instruments, such as shells, brackets, bases, partitions, tools, etc., are made of high-quality aluminum alloy precision profiles, pipes, wires, and high-surface sheets.

- Pharmaceutical production and packaging. Aluminum has been widely used in equipment and facilities used in the pharmaceutical production process. The soft and hard packaging of pharmaceuticals is one of the main uses of aluminum and aluminum alloy sheets and foils.

Is aluminum safe for humans?

A lot of medical equipment is not directly inserted into the human body. For example, one common use for aluminum is in stethoscopes, thanks to its lightweight and durability. For any metal that’s going to be inserted inside the human body, medical implants that may be used either temporarily or permanently, the concept of biocompatibility is essential. While aluminium is not an approved material for implants, it is often used in disposable and ancillary equipment for surgical and medical procedures.

One way to ensure that medical equipment is biocompatible is to anodize the surface. This is a method for increasing the surface protection of aluminum material and makes it better able to withstand corrosive environments. An anodized coating helps to enhance aluminum’s natural corrosion resistance. If necessary, an anodized aluminium part can also have additional sealing added as well.

The anodizing process involves the part being submerged in an acidic bath containing an electrical current. The tank wall will have a cathode, allowing the aluminum to naturally become an anode. The electricity causes oxygen ions to bond with the aluminum surface, improving the natural process of passivation discussed earlier.