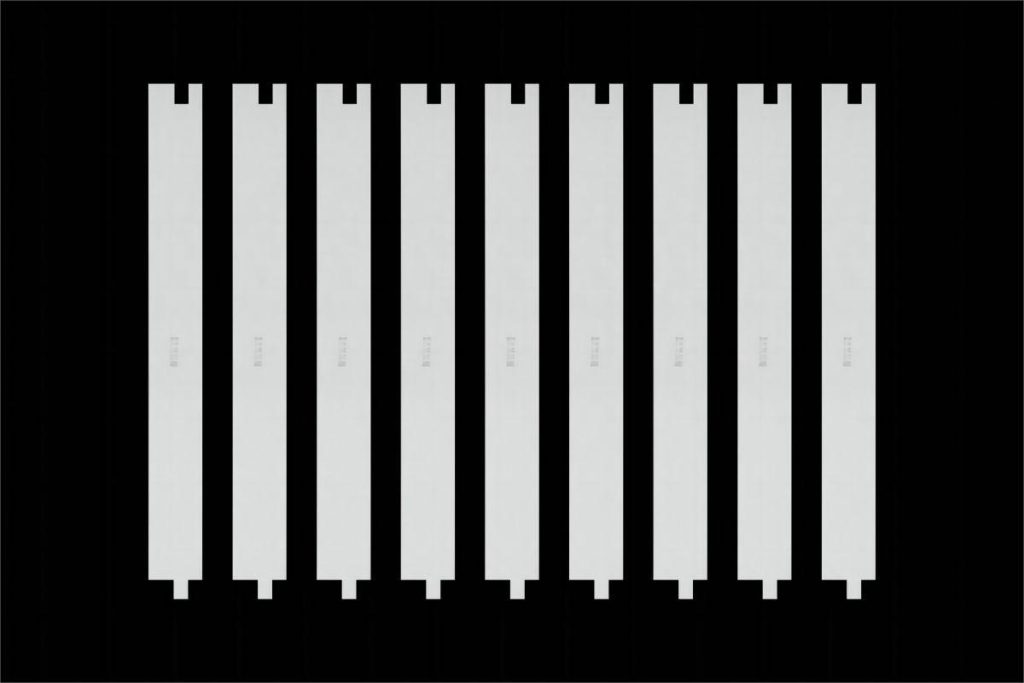

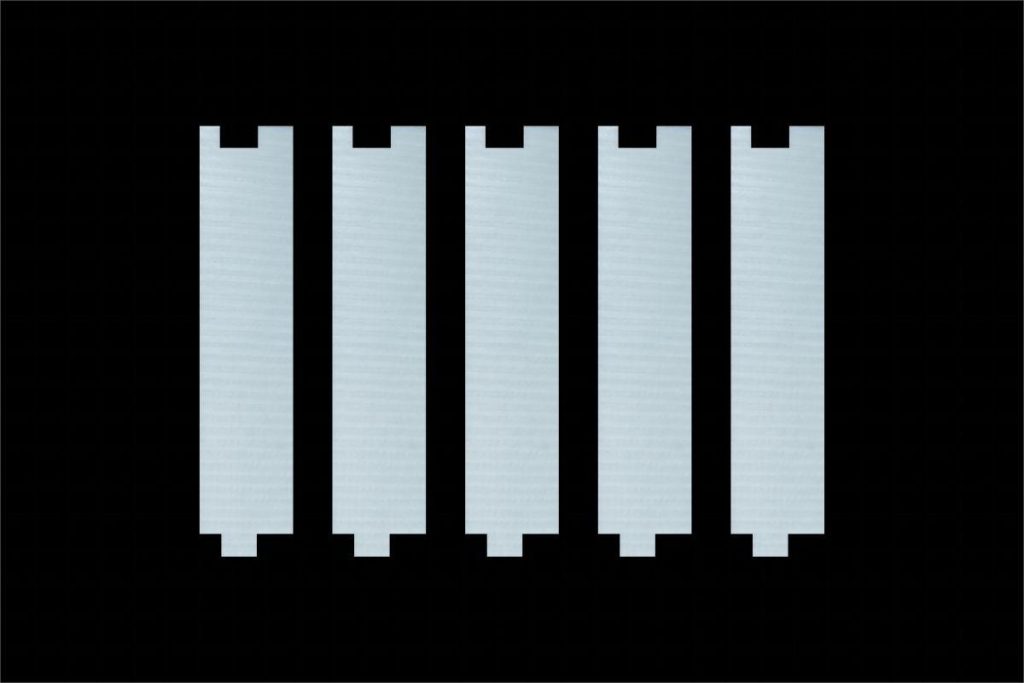

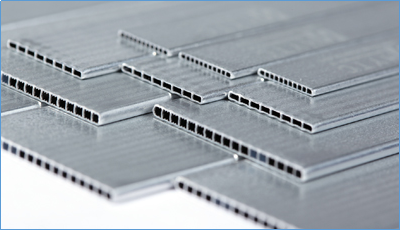

Aluminum materials have always been the most common and widely used materials in industrial materials. After updating according to conventional aluminum sheets, aluminum tubes, and other aluminium materials, more aluminum processing materials such as aluminium foils and aluminum coils have been expanded.

But carbon fiber is replacing aluminum in more and more applications and has been doing so for the past few decades.

These fibers are known for their extraordinary strength and stiffness, and they are also very lightweight. Carbon fiber strands are combined with various resins to form composite materials.

These composite materials take advantage of the properties of fibers and resins. This article provides a performance comparison of carbon fiber versus aluminum, as well as the advantages and disadvantages of each material.

Performance comparison of carbon fiber and aluminum

In order to better compare who has better performance between aluminium and carbon fiber such as aluminum plates. We tested the following properties of carbon fiber and aluminum and got the difference between them.

- Modulus of elasticity = the “stiffness” of the material. The ratio of stress to strain in a material. The slope of the stress-strain curve of material in its elastic region.

- Ultimate Tensile Strength = The maximum stress a material can withstand before breaking.

- Density = mass per unit volume of material.

- Specific stiffness = elastic modulus divided by material density. Used to compare materials with different densities.

- Specific Tensile Strength = Tensile Strength divided by Material Density.

| Measurement | Carbon fiber | Aluminum | Carbon/Aluminum Comparison |

| Elastic Modulus (E) GPa | 70 | 68.9 | 100% |

| Tensile strength (σ) MPa | 1035 | 450 | 230% |

| Density (ρ) g/cm3 | 1.6 | 2.7 | 59% |

| Specific stiffness (E/ρ) | 43.8 | 25.6 | 171% |

| Specific tensile strength (σ/ρ) | 647 | 166 | 389% |

Note: Many factors can affect these numbers. These are generalizations; not absolute measurements. For example, different carbon fiber materials are available with higher stiffness or strength, often at a trade-off in terms of reductions in other properties.

It can be seen from the figure that the specific tensile strength of carbon fiber is about 3.8 times that of aluminum, and the specific stiffness is 1.71 times that of aluminum. In general, carbon fiber performs better than aluminium.

Comparison of thermal properties of carbon fiber and aluminum

| Measurement | Carbon fiber | Aluminum | Carbon/Aluminum Comparison |

| Thermal expansion | 2 inches/inch/°F | 13 inches/inch/°F | 6.5 |

In addition to measuring their physical properties, we also test their thermal properties.

Notably, thermal expansion describes the change in dimensions of material as the temperature changes. The thermal expansion of aluminium is about six times that of carbon fiber.

The Pros and Cons of Aluminum and Carbon Fiber

When designing advanced materials and systems, engineers must determine the material properties that are most important for a specific application. When high strength is important to weight or high stiffness is important to weight, carbon fiber is the obvious choice.

When it comes to structural design, designers should consider carbon fiber as a better material when adding weight reduces service life or results in performance degradation. When toughness is essential, Intel Carbon Fiber is easily combined with other materials to obtain the necessary properties.

So, what about aluminum materials in the future?

Carbon fiber has so many advantages, so what about aluminum in the future? Will aluminium be replaced by carbon fiber?

The cost of carbon fiber has always been the most troublesome problem, and the high cost has always been prohibitive. Therefore, most carbon fiber is currently used in the production of customized products. Then, as the main material for mass production, aluminum will have broad application space not only now, but also in the future.