At present, air conditioners are gradually developing in the direction of miniaturization, high efficiency, and long life. The air-conditioning heat exchange fins are also developing in the direction of ultra-thin and high-strength. In the 1980s, the thickness of the heat exchange fins was 0.15-0.2ra. And today’s thickness is only between 0.09 to 0.15mm.

In addition, to improve the service life of air conditioners, reduce power consumption, improve ventilation quality and improve the cooling effect, coated heat exchange fins with various functions have been developed one after. Heat exchangers, surface hydrophobic heat exchangers, mildew-proof heat exchangers, and self-lubricating heat exchangers, etc.

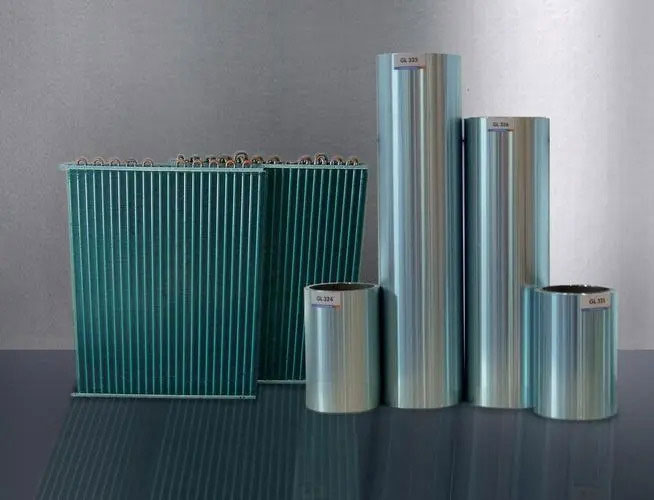

Classification of air conditioner aluminum foil

1. Uncoated aluminum foil

Uncoated aluminum foil refers to aluminum foil that has been rolled and annealed without any form of surface treatment. About 15 years ago, the aluminum foils used for air conditioner heat exchangers were all uncoated aluminum foils. Even today, about 50% of the fins used by aluminum foil manufacturers in most countries are still uncoated foils.

2. Coated aluminum foil

The so-called coated aluminum foil is to reprocess the surface of the uncoated aluminum foil to make it have some special function. In countries with rapid technological development such as Japan and Germany, the use of coated aluminum foil has a history of more than 15 years.

3. Corrosion-resistant aluminum foil

The surface of the corrosion-resistant aluminum foil product has a certain anti-corrosion protective layer. The air-conditioning heat exchange fins made of this product can be used in relatively harsh areas and can significantly improve the service life of the air conditioner.

At the same time, due to the improvement of the corrosion resistance of the heat exchange sheet, the generation of surface corrosion powder is greatly reduced, thereby improving the ventilation quality and purifying the air in the air-conditioned room.

What is Uncoated Air Conditioning Aluminum Foil?

1. Chemical composition of uncoated air conditioner aluminum foil

The alloy grades of aluminum foil for heat exchange fins mainly include 1100, 1200, 8011, 8006, etc. From the perspective of use, air conditioners do not have strict requirements on the chemical composition of aluminum heat exchange fins.

Without surface treatment, 3A21 aluminum alloy has relatively good corrosion resistance, high mechanical properties such as strength and elongation, and high hardness.

The choice of the alloy depends primarily on the final mechanical properties the material can achieve and the ease of the ant process. For example, the 1100 aluminum alloy with higher purity is easier to roll, while the 8011 alloy is more difficult.

2. Mechanical properties

Mechanical properties mainly refer to the tensile strength, elongation, and cupping value of aluminum foil. From the perspective of use, it is hoped that these three indicators are as high as possible, but in terms of the material itself, these three indicators are contradictory, that is, when the tensile strength of the aluminum foil is relatively high, the elongation index will decrease; When the elongation of the aluminum foil is increased, the tensile strength will decrease.

Therefore, in practical applications, the intermediate value of the mechanical properties is generally taken, and the specific strength and plasticity values are related to the punching die during the processing of the heat exchange fin.

Generally, the punching process of heat exchange fins is divided into 3 types: stretching type and non-stretching type. The mold for stretch punching requires better plasticity of the aluminum foil, that is, the elongation is higher, and the relative strength value can be slightly lower; while the non-stretch mold requires higher strength of the aluminum foil, and plasticity is a secondary indicator. There are many factors affecting the mechanical properties of aluminum foil, mainly the chemical composition and processing technology of aluminum foil.

And through the adjustment of chemical composition and processing technology, the matching value of aluminum foil strength and plasticity can be changed to a limited extent.

According to the different requirements for mechanical properties of heat exchange fins, there are currently three main use states of aluminum foil: H22, H24, and H26. Each state corresponds to a certain range of strength and plasticity.

What is Coated Air Conditioning Aluminum Foil?

Coated aluminum foil is formed after surface treatment based on non-coated aluminum foil. In addition to the chemical composition, mechanical properties, and geometric dimensions required by the above non-coated aluminum foil, it should also have a good shape and shape. coating properties.

1. Plate type of aluminum foil

First of all, the production process of coated aluminum foil requires that the aluminum foil has a good shape, which is a prerequisite for the production of coated aluminum foil. The unit for measuring the shape index is I.

The general coating production equipment’s requirements for the plate shape are within 20-40I. If it is more significant than this value, a tension straightening system needs to be added before the coating equipment. The aluminum strip running route of the coating equipment is long, and there are many processing procedures and guide rollers.

Therefore, if the tension straightening system is not equipped, once the plate shape is not good, it is easy to fold during operation, failing in production. The air-conditioning production process also has higher requirements on the shape of the aluminum foil.

The general heat exchange fin punching production line uses the vacuum suction cup method to transfer the aluminum foil. If the shape of the aluminum foil is not good and the surface is not flat, the vacuum suction method of the aluminum foil will not work normally. Therefore, the plate shape is not only an important technical index of coated aluminum foil but also of uncoated aluminum foil.

2. Coating properties

As mentioned above, there are many types of coated aluminum foils for heat exchange fins. At present, the coated aluminum foils used in the market are mainly hydrophilic. Therefore, only the coating performance indicators of hydrophilic aluminum foils are discussed here.

3. Coating thickness

The thickness of the coating film on the surface of the aluminum foil is not strictly specified, and it is generally below 3/1m. Because the price of coatings is generally more expensive, the thinner the coating film thickness is under the premise of meeting the performance requirements, the lower the production cost. The thickness of the coating directly affects the performance indicators of the coating, so the coating thickness on the surface of the aluminum foil is required to be uniform.

4. Coating adhesion

Coating adhesion is an indicator of the adhesion fastness of aluminum foil to its surface coating. If the coating adhesion is too small, the surface coating of the coated aluminum foil will easily fall off during further processing and use, which will seriously affect the weight of the coated aluminum foil. Therefore, the stronger the coating adhesion, the better.

Coating adhesion can generally only be tested qualitatively. The main testing methods include the abrasion resistance test, cross-cut test, and cupping technique.

5. Hydrophilic properties

After the hydrophilic aluminum foil is used for some time, the hydrophilic properties of the surface will be affected by various environmental factors. Therefore, the hydrophilic performance is generally divided into the initial hydrophilicity and the hydrophilicity after the environmental resistance test.

The quality of hydrophilic performance is mainly measured by the size of the angle a. The initial hydrophilicity requirements of general products are a<100, and the hydrophilicity requirements after the environmental resistance test are a<250. The contact angle can be measured by using a special contact angle measuring instrument. It can also be calculated by the size of the area occupied by a certain volume of water droplets on the surface of the aluminum foil.

6. Corrosion resistance

Corrosion resistance is mainly reflected in 3 aspects:

(1) Alkali resistance. Since the lubricating oil on the surface of the heat exchange fin after punching needs to be removed with an alkaline cleaning agent, the functional coating on the surface of the aluminum foil must have a certain degree of alkali resistance. Generally, it is required to soak in 20% NaOH solution for 3 minutes without foaming ;

(2) Salt spray corrosion resistance. Generally, no corrosion spots are required for 500 hours in the test condition of 35 ℃ and 3% salt water spray environment. The resistance to salt spray corrosion is directly related to the service life of the heat exchange fins. In coastal areas, due to the high salt content in the air, there are higher requirements for the salt spray corrosion resistance of the heat exchange fins;

(3) It is the resistance to heat and humidity, that is, the corrosion resistance of long-term storage at a certain temperature and certain humidity. This performance is also an important indicator to measure the weatherability of the heat exchanger fins.