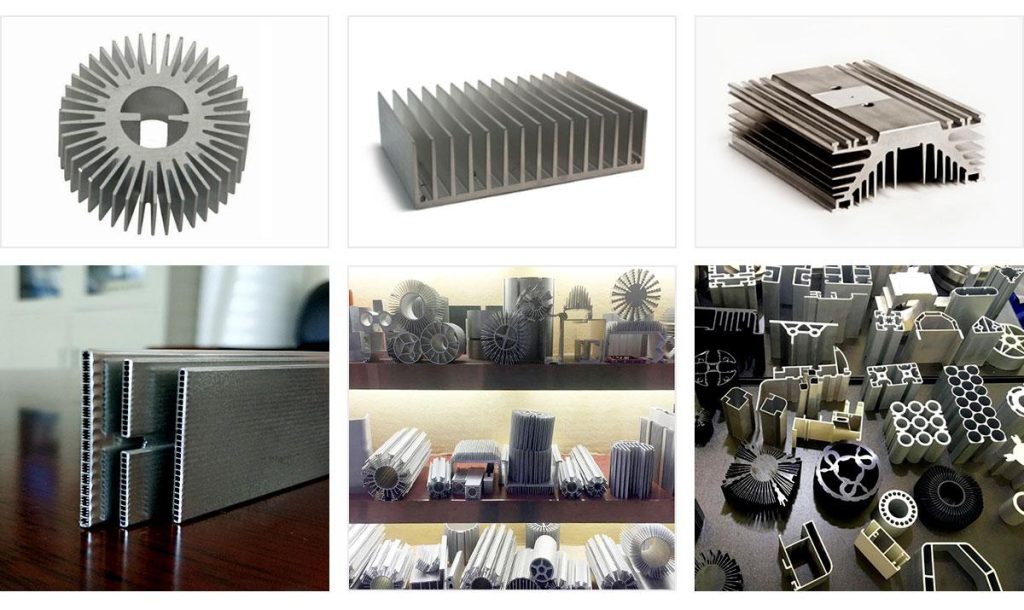

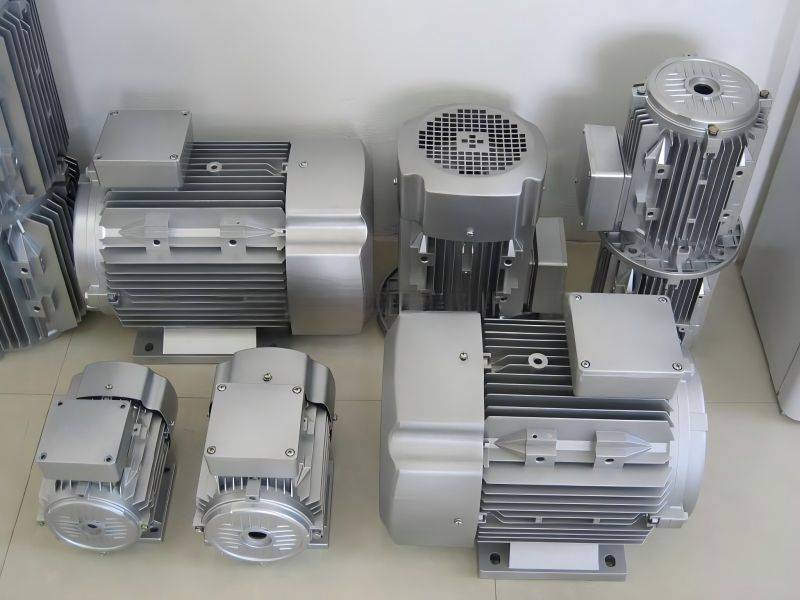

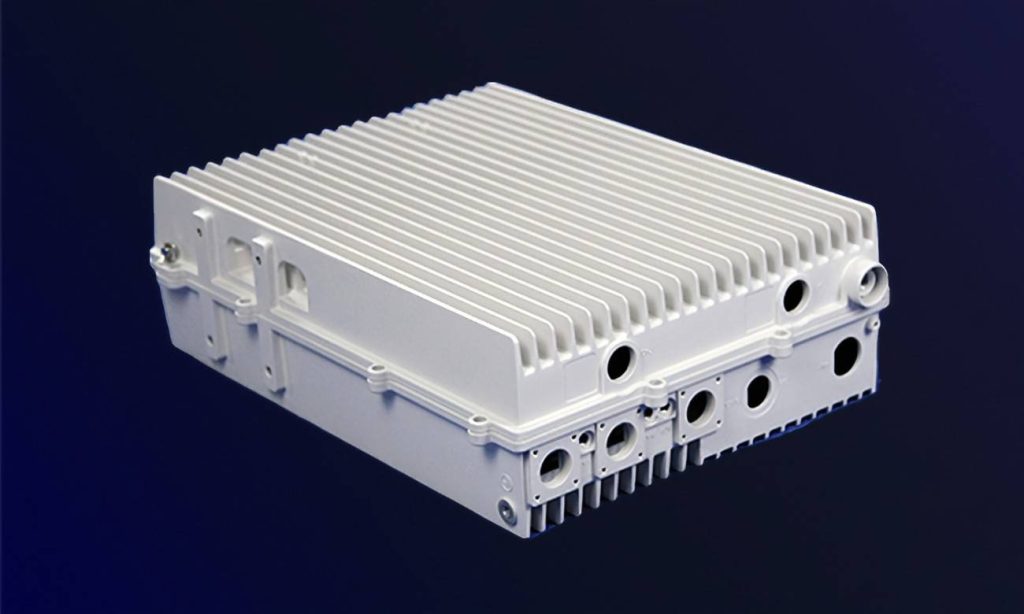

The cross-sectional shape of aluminum channel profiles is the core carrier for realizing their functions. In the global aluminum profile market in 2023, industrial applications accounted for 38% (Data source: CRU International), of which more than 60% of customization needs are directly related to the cross-sectional shape. The geometric structure formed by the precision extrusion process not only determines the mechanical strength and heat dissipation performance of the profile, but also affects its system adaptability in electrical protection, optical control, and architectural mechanics. This article analyzes the morphological characteristics of typical channels in three major fields to reveal the “shape-function” mapping relationship in industrial design.

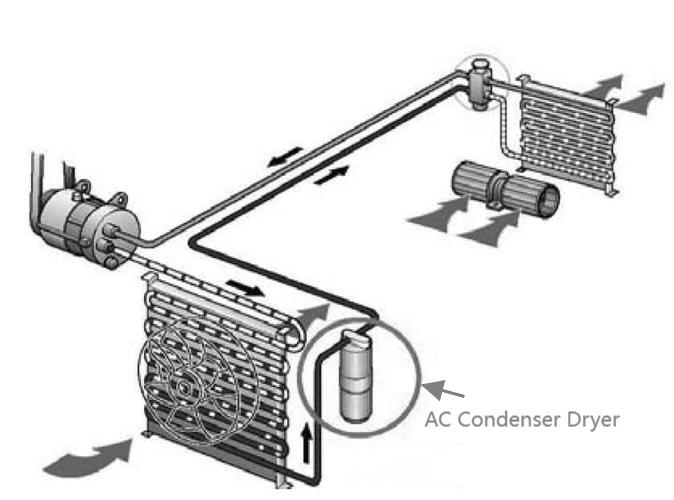

Aluminum Channel in Electrical: Protection and Integration

In electrical systems, aluminum channels play a pivotal role in supporting and protecting cables, conduits, and other electrical components. Some common shapes are:

C-Shaped Channels: Modular Installation

These channels are commonly used for cable management. Their open design allows for easy installation and maintenance of cables, making them suitable for data centers and industrial settings.

Technical Specifications

- DIN rail compatibility: 35 mm width, 7.5 mm depth (Siemens S7-1500 series)

- Anti-vibration design: Reinforced ribs increase natural frequency >200 Hz

- Surface treatment: Conductive oxidation (5-8 μm film thickness)

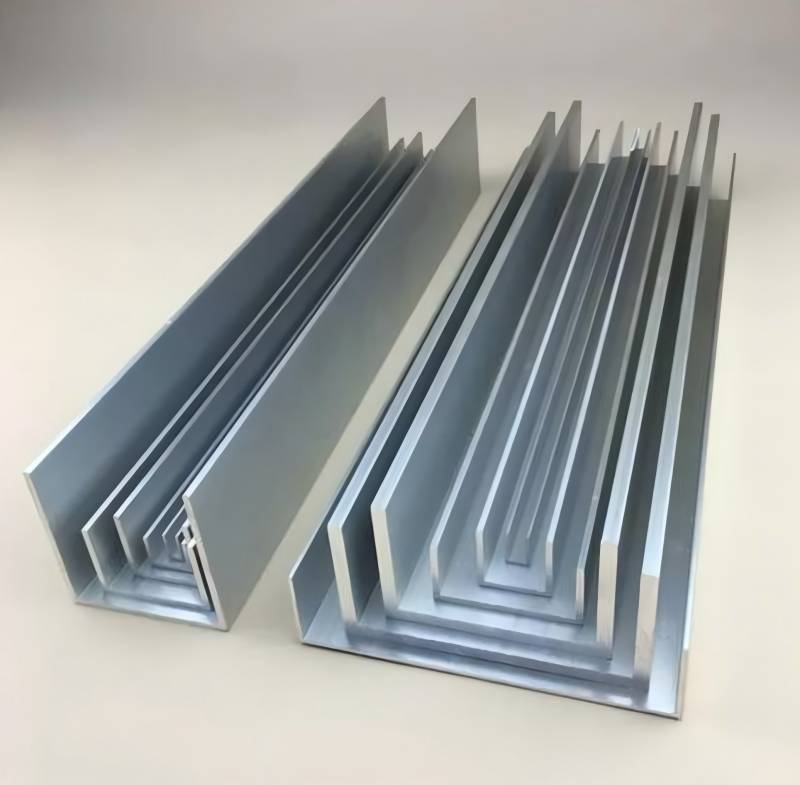

U-Shaped Channels: Standardized Cable Management

U-shaped aluminum channels are frequently employed as protective housings for electrical conduits. Their sturdy construction ensures that cables are shielded from physical damage and environmental factors such as moisture or dust.

Technical Specifications

- Cross-section: Depth 20-100 mm, slot width 6/8/10 mm (IEC 61534 compliant)

- Mechanical properties: Vertical compressive strength ≥500 N/100 mm at 1.8 mm wall thickness

- Innovation: 45° snap-fit cover design (insertion force 15-20 N)

U/C-channel systems increased wiring density by 40% and maintenance efficiency by 65% (ABB data), achieving 98% component interchangeability.

Aluminum Channel in Lighting: Balance of Light and Heat

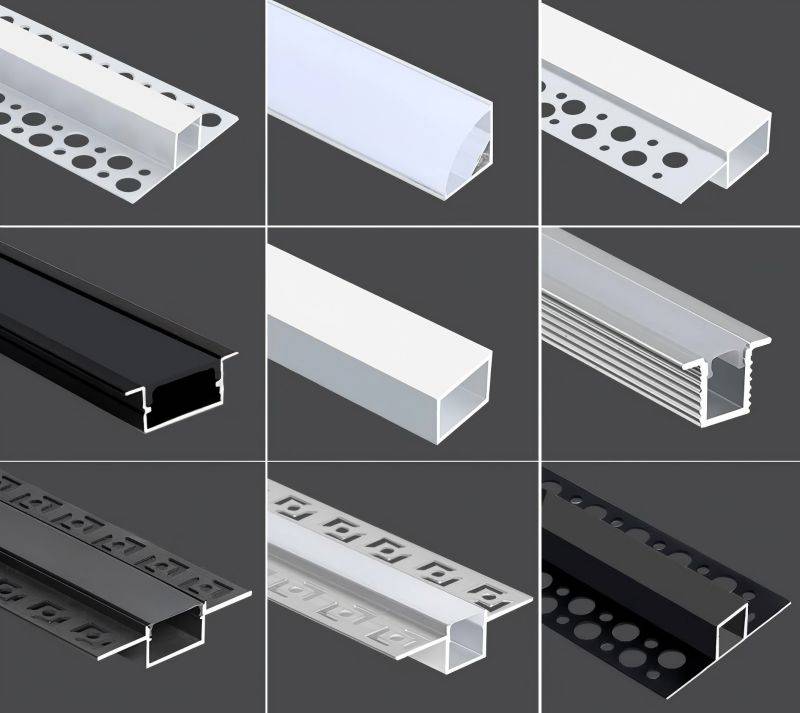

Aluminum channels are a staple in the lighting industry due to their ability to enhance both functionality and aesthetics. They are commonly used to house LED strips, ensuring efficient heat dissipation and a polished finish. Some common types are:

Flat Channels

Flat aluminum channels are used to mount LED strips on flat surfaces. They provide a clean and professional appearance while protecting the LED strips from damage.

Recessed Channels

These channels are designed to be embedded into walls, ceilings, or furniture, creating a sleek, seamless look. Recessed aluminum channels are popular in modern architectural lighting.

Angled Channels

Angled aluminum channels are used to direct light at specific angles, making them ideal for under-cabinet lighting, display cases, or accent lighting.

V-Channels

V-shaped aluminum channels are utilized to create focused lighting effects. Their angular design is perfect for corner installations and achieving a concentrated light beam. Technical specifications for example:

- Optical control: ±15° beam width at 90° opening

- Thermal design: 8 mm fin spacing (35% larger surface than U-channels)

- Material: 6060-T66 alloy (CTE 23.6×10⁻⁶/°C)

Circular Channels

Circular aluminum channels are designed for cylindrical lighting fixtures, offering uniform light distribution. They are often used in pendant lights and decorative installations. Technical specifications for example:

- Structure: Φ50 mm profile for 144 LED/m RGBW strips

- Optical performance: 92% transmittance acrylic diffuser

- Protection: IP68 rating (1 m water immersion tested)

V/circular systems reduced energy consumption by 30% while achieving 150 lm/W efficacy (Osram data), resolving glare and thermal conflicts.

In addition to their protective properties, aluminum channels act as heat sinks, extending the lifespan of LEDs by dissipating heat. This functionality, combined with their sleek designs, makes them indispensable in contemporary lighting solutions.

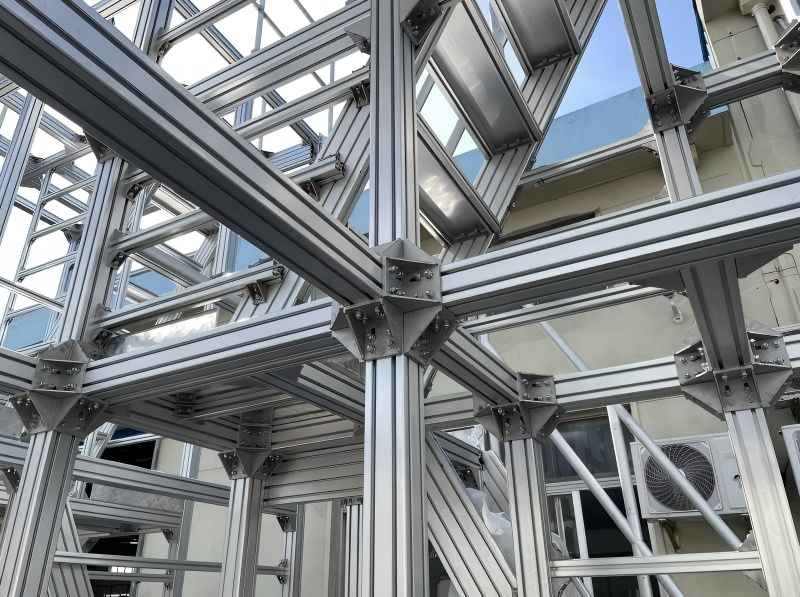

Aluminum Channel in Structural: Optimization of Force and Shape

In structural applications, aluminum channels provide strength and support in a variety of construction and engineering projects. Their corrosion resistance and strength-to-weight ratio make them suitable for a range of structural uses:

I-Channels: Bending Resistance Maximized Technical

Aluminum I-channels are employed in framing and load-bearing structures. Their design ensures excellent load distribution and durability.

Technical Specifications

- Mechanical performance: Section modulus Z≥28 cm³ (3 m span supports 1.2 tons)

- Connection: Grade 8.8 T-bolts (290 N·m torque)

- Surface: 50 μm micro-arc oxidation (HV >800)

L-Channels (Angle Channels)

L-shaped channels are often used for reinforcement and edging in construction projects. They add strength to corners and joints, ensuring structural stability.

Hat Channels

Hat-shaped aluminum channels are frequently used in roofing and ceiling installations. Their unique shape provides additional support and rigidity to panels and other materials.

Structural applications often demand materials that can withstand environmental stresses without compromising integrity. Aluminum channels meet these demands, offering a long-lasting, maintenance-free solution for various construction challenges.

Aluminum channels are incredibly versatile building components that play a crucial role in electrical, lighting, and structural applications. Their unique properties, including light weight, corrosion resistance, and ease of fabrication, make them a desirable material across diverse industries. From cable management in electrical systems to sleek housings for LED lighting and lightweight framing in structural applications, aluminum channels provide practical and cost-effective solutions. Understanding the different types and sizes of channels available allows engineers, designers, and contractors to select the optimal profile for their specific project needs, ensuring both functionality and aesthetic appeal. For more customized aluminum channel shapes, please feel free to contact CHAL.