Aluminum wire is a popular choice for electrical wiring due to its excellent conductivity, lightweight, and affordability. However, when it comes to choosing between insulated and bare aluminum wire, it’s important to consider a range of factors to determine which is the best option for your needs. In this article, we’ll compare the advantages and disadvantages of both types of aluminum wire to help you make an informed decision.

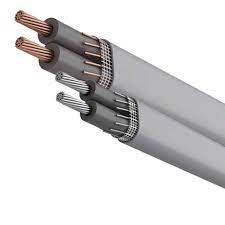

Advantages of Bare Aluminum Wire

Bare aluminum wire is often used in applications where there is minimal risk of corrosion or moisture, such as overhead power transmission. Here are some of the advantages of bare aluminum wire:

Cost Advantage of Bare Aluminum Wire

Bare aluminum wire is typically less expensive than insulated aluminum wire because it requires less manufacturing and materials. Since the wire is not coated with insulation, there are fewer steps involved in the production process. This makes bare aluminum wire a popular choice for applications where cost is a primary concern. It is commonly used in electrical transmission and distribution systems, as well as in grounding applications. However, it’s important to note that bare aluminum wire can be more susceptible to corrosion and oxidation, which can lead to electrical issues over time.

Flexibility Advantage of Bare Aluminum Wire

Bare aluminum wire is more flexible than insulated aluminum wire. This makes it easier to work with in tight spaces or when routing the wire around obstacles. The lack of insulation also allows the wire to be bent and twisted more easily, without the risk of damaging the insulation. This can be especially advantageous in applications where the wire needs to be routed around corners or through narrow openings. However, it’s important to note that bare aluminum wire can be more susceptible to physical damage, such as bending or kinking, which can impact its performance over time.

Conductivity Advantage of Bare Aluminum Wire

Bare aluminum wire has a higher conductivity than insulated aluminum wire. This means that it is more efficient at transmitting electrical current, which can be an advantage in some applications. Bare aluminum wire is commonly used in high-voltage transmission lines because of its high conductivity and ability to carry large amounts of current over long distances. However, it’s important to note that bare aluminum wire is also more susceptible to environmental factors, such as moisture and humidity, which can impact its conductivity over time. Insulated aluminum wire provides a layer of protection against these environmental factors, which can be an advantage in certain applications.

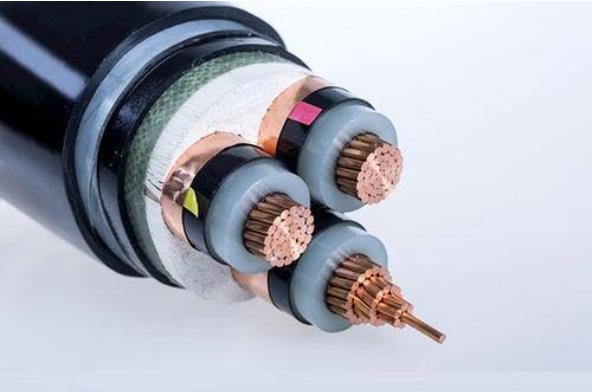

Advantages of Insulated Aluminum Wire

Insulated aluminum wire is typically used in residential and commercial electrical wiring applications, where it is exposed to moisture and other environmental factors that could cause corrosion. Here are some of the advantages of insulated aluminum wire:

Corrosion Resistance Advantage of Insulated Aluminum Wire

One of the biggest advantages of insulated aluminum wire is its resistance to corrosion. The insulation coating helps to protect the wire from moisture and other environmental factors that could cause the wire to degrade over time. Corrosion can be a major problem for electrical systems, as it can cause wires to become brittle and break, which can lead to system failure or safety hazards. The insulated aluminum wire helps to mitigate this risk by providing an extra layer of protection against corrosion, ensuring that the wire remains in good condition for longer.

Durability Advantage of Insulated Aluminum Wire

Insulated aluminum wire is more durable than bare aluminum wire. The insulation coating provides an extra layer of protection that can help to prevent damage to the wire, which can extend the life of the wire and reduce the need for repairs or replacements. This is particularly important in applications where the wire is exposed to mechanical stress, such as in high-vibration environments. Insulated aluminum wire is less likely to become damaged or broken under these conditions, which can help to ensure that the electrical system operates reliably over time.

Moisture Resistance Advantage of Insulated Aluminum Wire

Insulated aluminum wire is also more resistant to moisture than bare aluminum wire. This makes it a better choice for applications where the wire will be exposed to moisture or humidity, such as in outdoor or damp environments. Moisture can cause the bare aluminum wire to corrode and degrade over time, which can lead to system failure or safety hazards. The insulated aluminum wire helps to mitigate this risk by providing an extra layer of protection against moisture, ensuring that the wire remains in good condition even in damp conditions. This can help to extend the life of the wire and improve the reliability of the electrical system overall.

Factors to Consider When Choosing Between Bare and Insulated Aluminum Wire

When choosing between bare and insulated aluminum wire, there are several factors to consider. Here are some of the key considerations:

Type of Application

The type of application will determine whether bare or insulated aluminum wire is the best choice. Bare aluminum wire is generally more suitable for applications where there is minimal risk of corrosion or moisture, while insulated aluminum wire is better for applications where the wire will be exposed to moisture or other environmental factors.

Environmental Factors

Environmental factors such as moisture, humidity, and temperature should also be considered when choosing between bare and insulated aluminum wire. Insulated aluminum wire is more suitable for use in environments where there is a risk of corrosion or moisture, as the protective coating will help to prevent damage to the wire.

Electrical Requirements

The electrical requirements of the application should also be taken into consideration. Bare aluminum wire has a higher conductivity than insulated aluminum wire, making it more efficient at transmitting electrical current. However, insulated aluminum wire is more suitable for applications that require durability and resistance to corrosion.

Conclusion

When it comes to choosing between bare and insulated aluminum wire, there is no one-size-fits-all solution. Each type of wire has its own unique advantages and disadvantages, and the best choice will depend on the specific needs of the application. By considering factors such as environmental factors, electrical requirements, and cost, you can make an informed decision about which type of aluminum wire is best suited for your needs. It’s important to consult with a professional electrician or electrical engineer to ensure that you choose the right type of wire for your application and that the wire is installed and used safely and correctly. With the right choice of aluminum wire, you can ensure that your electrical system operates efficiently and reliably for years to come.

Related Products

Related Articles