Cool, pleasant air is only a switch away during the scorching summer heat. Simply turn on the air conditioner and you’ll be surrounded by cool air in minutes. Aside from the various factors that determine which type of air conditioner is superior, there is an age-old debate over whether copper coil or aluminium coil is superior.

The significance of coils in air conditioners

The core of air conditioning is a refrigerant gas that compresses from a gaseous state to a liquid state and then returns to a gaseous state by absorbing heat from the room. It goes through a cooling process that is divided into four stages:

Compression: The gas is pressurized and converted into a high-pressure hot liquid.

Condensation: The liquid flows through a coil where the high-pressure hot liquid refrigerant is converted into a cooler liquid by releasing heat into the outside air. This is a part where coils are used.

Expansion Valve: A valve then converts high-pressure liquid to low-pressure liquid.

Evaporation: The low-pressure liquid passes through an evaporation coil, absorbing heat from the surrounding environment and changing from liquid to gas. This process takes place in the indoor unit, while the others take place in the outdoor unit (in the case of split ACS).

Essentially, heat from the inside air is transferred to the outside air via the coils.

The refrigerant in the evaporation coils evaporates (changes from liquid to gas) by absorbing heat from the air passing over it (air from the room). The cooled air (from the room) is directed back into the room. The gaseous refrigerant is then compressed and passed through condensation coils, where it condenses and releases heat into the surrounding air. Exhaust fans are used to blow out the warm air.

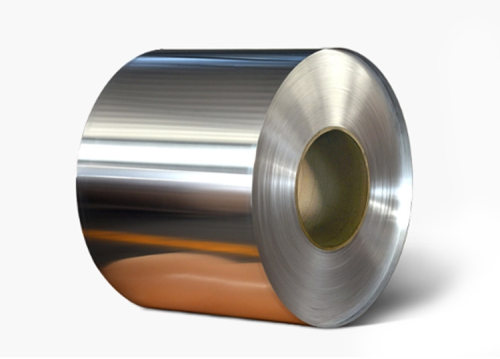

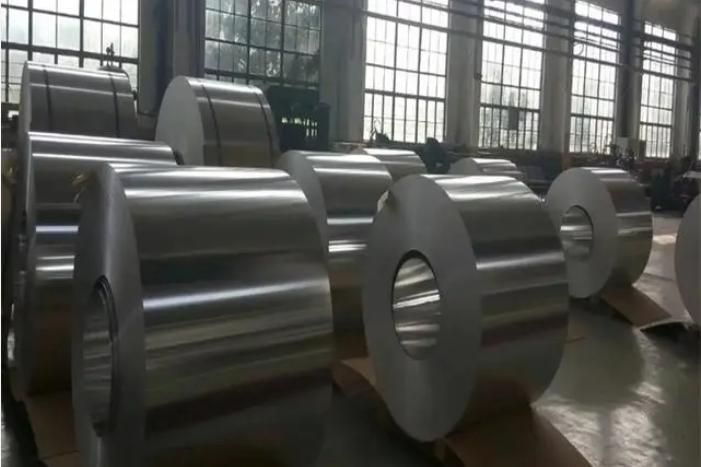

Differences between Aluminium coil and Copper coil

1) Heat transfer characteristics:

Because heat is transferred in the coils, it is critical that the metal has good heat transfer characteristics. The copper coil has a higher heat transfer coefficient than the aluminium coil. This means that copper is a superior heat exchanger to the aluminum coil.

2) Cost and Pliability:

Copper is more expensive than the aluminium coil, which raises the cost of manufacturing an air conditioner and thus the price of the air conditioner. The aluminium coil has become the preferred material among manufacturers in order to reduce the unit cost of manufacturing ACs.

Another factor to consider is adaptability. An aluminium coil, as opposed to a copper coil, can be bent into the desired shapes more easily. As a result, to make a coil of the same size and shape, approximately three times more copper is required, increasing the cost of the process.

However, in order to reduce the cost of AC with copper coils, thinner and thinner copper coils are being manufactured these days.

3) Strength and reliability:

Copper coil is far easier to repair in the field than the aluminium coil. When aluminum coils are damaged, they frequently require replacement. Copper coils are significantly stronger than aluminium coil. As a result, they are long-lasting.

4) Ease of maintenance:

Because the condenser coils are located in the unit, often installed outside the home, they are exposed to dust and harsh weather conditions and require routine cleaning for proper performance. Having said that, because of their durability, copper coils are simple to clean and maintain. However, because aluminium coil are weak, they must be maintained in a sturdy cabinet to prevent damage. They are therefore challenging to maintain and clean.

5) Corrosion:

The longevity of an air conditioner is significantly influenced by corrosion. Coils are damaged by corrosion, which hinders heat transfer and also causes leaking. Therefore, it is crucial to prevent corrosion on the coils. As a result of the increased air moisture content in these regions, corrosion damages are more common in humid climates and for residents who live close to seacoasts and saltwater bodies.

A non-conducting layer develops over the coils as a result of this corrosion, which lowers the coils’ ability to exchange heat. Today, numerous cutting-edge solutions have been designed to shield AC coils from corrosion and lengthen their valuable lives. (Tip: When purchasing an air conditioner, look for corrosion protection methods like coating the coils, etc.)

Why choose an aluminum coil?

Aluminum coils provide oxidation protection, which copper does not. All aluminum coils are resistant to formicary corrosion and will not rust as quickly as copper. Aluminum coils are also more resistant to pinhole leaks, extending the life of your HVAC system. When a coil leaks, refrigerant is lost, and your home cannot be properly cooled. These leaks are frequently among the most costly problems to repair in an HVAC system. According to our experts, over the last few decades, more service technicians and brands have come to trust aluminum coil’s durability over copper’s.