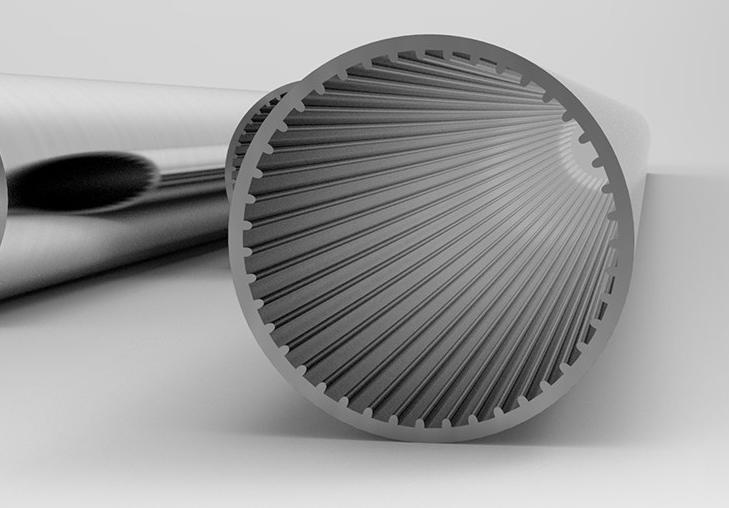

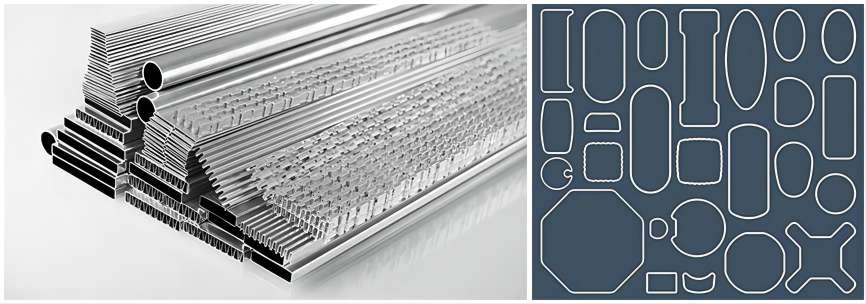

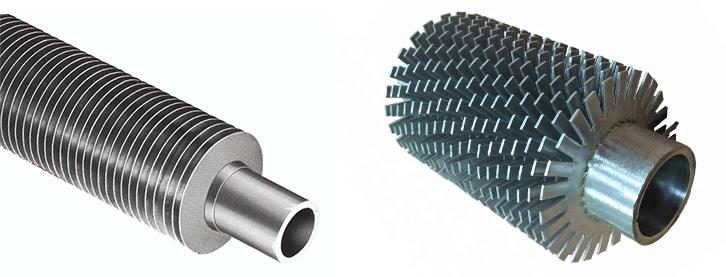

Aluminum finned tubes are a cornerstone of modern heat exchange systems, prized for their exceptional heat conductivity and lightweight design. However, they are susceptible to corrosion, a significant drawback when operating in humid environments rife with corrosive media. This vulnerability not only diminishes their lifespan but can also pose safety hazards. Therefore, fortifying the corrosion resistance of aluminum finned tubes becomes crucial for their successful adaptation to demanding working conditions. This article delves into the challenges and unveils a multi-pronged approach to overcome them.

Why Should Enhance the Corrosion Resistance of Aluminum Finned Tubes?

Aluminum, by its very nature, is a reactive metal. When exposed to moisture or corrosive media, it readily undergoes oxidation and corrosion. This deteriorates the structural integrity of the tubes, leading to:

- Reduced heat transfer efficiency: Corrosion thwarts the ability of aluminum to transfer heat effectively, hindering the performance of the entire heat exchange system.

- Loss of material: As corrosion eats away at the aluminum, the wall thickness of the tubes diminishes, jeopardizing their structural stability and increasing the risk of leaks and failures.

- Safety hazards: Breaches in the tubes due to corrosion can lead to the leakage of hazardous fluids or pressurization failures, posing a threat to personnel and equipment.

Tips for Enhancing Corrosion Resistance of Aluminum Finned Tubes

To effectively combat corrosion and ensure the longevity of aluminum finned tubes in harsh environments, a comprehensive approach encompassing various strategies is necessary.

- Material Selection and Optimization: The battle against corrosion begins at the very foundation – the material selection. Here’s where high-silicon aluminum alloys and aluminum-magnesium-silicon alloys (such as 6063) come to the fore. These alloys boast superior corrosion resistance compared to their conventional counterparts. Additionally, incorporating elements like zinc and copper into the alloy not only enhances strength but also promotes the formation of a protective oxide layer on the surface, further hindering corrosion.

- Surface Treatment Technology: Beyond material selection, surface treatment technologies offer another layer of defense against corrosion. Some prominent methods include:

- Anodizing: This process forms a uniform and dense aluminum oxide film, significantly bolstering the corrosion resistance of the aluminum material.

- Electrophoretic Coating: This method electrochemically deposits a layer of colorful, corrosion-resistant organic coating on the aluminum surface, providing both aesthetic appeal and practical protection.

- Thermal Spraying: Molten metal or ceramic materials are sprayed onto the aluminum surface, creating a robust barrier against corrosion and wear.

- Design Optimization: The design stage presents a golden opportunity to incorporate corrosion-resistant features. Here are key considerations:

- Minimizing stress points: Sharp edges and dead corners are breeding grounds for corrosion. Design modifications that eliminate these features, such as employing smooth transitions and rounded edges, are crucial.

- Structural enhancements: Implementing special structural designs like deflectors and additional heat dissipation fins can minimize the impact and wear of the fluid on the tube walls, thereby reducing the likelihood of corrosion.

- Use Anti-Corrosion Materials: The realm of corrosion resistance is constantly evolving, with innovative materials emerging as potential allies. Polymers and inorganic nanocomposites are prime examples, exhibiting remarkable resistance to weathering and chemicals, effectively shielding aluminum from harsh environments.

- Environmental Control: When feasible, manipulating the working environment can significantly impact corrosion rates. Techniques like controlling humidity, temperature, and the concentration of harmful gases in the air can contribute to mitigating corrosion in aluminum finned tubes. Additionally, regular maintenance and inspections are vital for the timely detection and treatment of any signs of corrosion, further extending the lifespan of the tubes.

- Research and Development: Continuous research and development efforts hold the key to unlocking even more effective corrosion-resistant solutions. By delving into theoretical research, conducting rigorous experimental verification, and implementing discoveries in practical applications, scientists and engineers can explore novel corrosion-resistant materials, processes, and technologies.

Aluminum Finned Tube Corrosion Types

The corrosion of aluminum finned tubes manifests in various forms, each posing unique challenges:

- Pitting Corrosion: This localized form of corrosion attacks specific points on the metal surface, often initiated by the presence of chloride ions (Cl-) or fluoride ions (F-). The presence of ions like copper (Cu2+) or zinc (Zn2+) can further accelerate the corrosion process.

- Uniform Corrosion: In specific solutions, such as a combination of phosphoric acid and sodium hydroxide, the protective oxide layer on aluminum breaks down, leading to a gradual and uniform thinning of the metal.

- Crevice Corrosion: When narrow gaps or crevices form between metal components, these confined spaces trap corrosive media, creating an environment conducive to accelerated corrosion.

- Intergranular Corrosion: This insidious form of corrosion targets the grain boundaries of the metal, where the electrochemical properties differ from the bulk material.

- Stress Corrosion Cracking (SCC): The combined action of tensile stress (either applied or residual) and a corrosive environment can lead to the brittle fracture of aluminum alloys, potentially causing catastrophic failure.

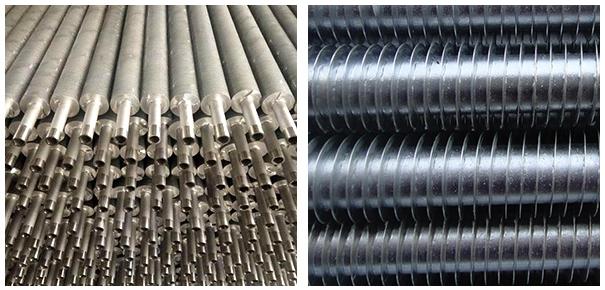

Corrosion Repair Techniques for Aluminum Finned Tubes

Combating corrosion in aluminum finned tubes requires a tailored approach, with the choice of repair technique dependent on the extent and type of damage. Here’s an overview of commonly employed methods:

- Welding Repair: Specialized welding techniques, such as explosion welding, friction welding, and laser welding, can be employed to repair damaged sections of aluminum finned tubes. Careful consideration of the tube’s structure, precise positioning, localized pre-treatment, and selection of appropriate welding parameters are essential for successful and reliable repairs.

- Chemical Descaling: Chemical descaling involves utilizing chemical reagents that react with the corrosion products on the tube’s surface, dissolving or converting them. While effective in removing corrosion, careful selection and handling of descaling agents are crucial to prevent further damage to the underlying metal.

- Mechanical Descaling: This method employs physical tools like brushes, sandpaper, or scrapers to remove corrosion and contaminants from the tube’s surface manually. In comparison, simple and cost-effective, mechanical descaling can potentially cause scratches or damage to the tube’s surface.

- High-Pressure Water Jet Descaling: High-pressure water jets generate a powerful stream that blasts away corrosion and debris from the tube’s surface. This method offers the advantages of efficiency and environmental friendliness, as it does not involve hazardous chemicals or mechanical abrasion.

Conclusion

Aluminum finned tubes offer exceptional heat exchange but are susceptible to corrosion in harsh environments. This vulnerability manifests in various forms, including pitting, uniform thinning, crevice attacks, and stress corrosion cracking. Fortunately, a multi-pronged approach exists to combat this challenge. Material selection with enhanced corrosion resistance is a starting point. Specialized surface treatments like anodizing and advanced repair techniques like welding and high-pressure water jetting can restore or extend the lifespan of affected tubes. By understanding the types of corrosion and employing these strategies, we can unlock the full potential of aluminum finned tubes for long-lasting, reliable performance in various industrial applications.