Aluminum Manufacturer in China

CHAL: Full-Service in Aluminum

CHAL Aluminium Corporation is a fully integrated aluminum company that provides all kinds of aluminium products and technical solutions. We are committed to being the leading supplier of aluminum profile, aluminum micro-channel tube, aluminum high frequency welded tube, aluminum drawn tube, aluminum seamless tube, aluminum machining parts and stamping parts, aluminum wire, aluminum heat transfer material, aluminum plate, sheet, strip, foil, rod and bar, die forgings, die castings. The products manufactured are widely used in the automotive industry, construction industry, HVAC/R and heat transfer industry, aviation, rail transportation, oceanic industry, etc.

Products Catalogue

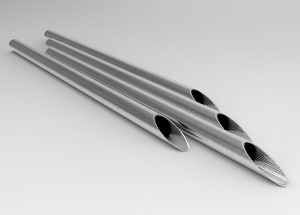

Aluminum Tube

– Micro Channel Tube

– Drawn Tubes

– High Frequency Welded Tube

– Seamless Tube

– Extruded Tube

– Composite Tube

– Header Pipe

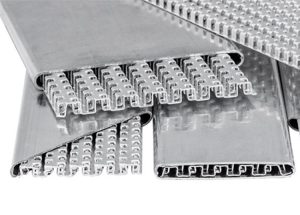

Aluminum Profiles

– Heat Sink

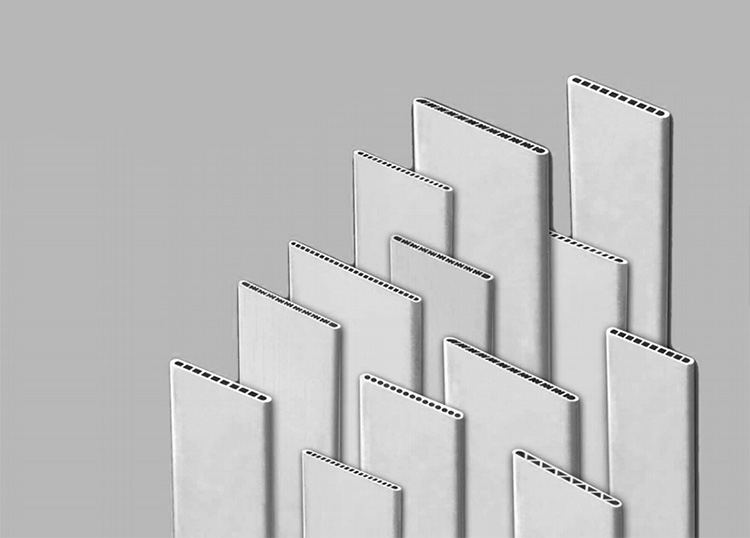

– Multi Channel Extrusion

– Motor Housing Extrusion

– Association I Beam

– Multi-Channel Tube

– Extrusion profile for mask machine

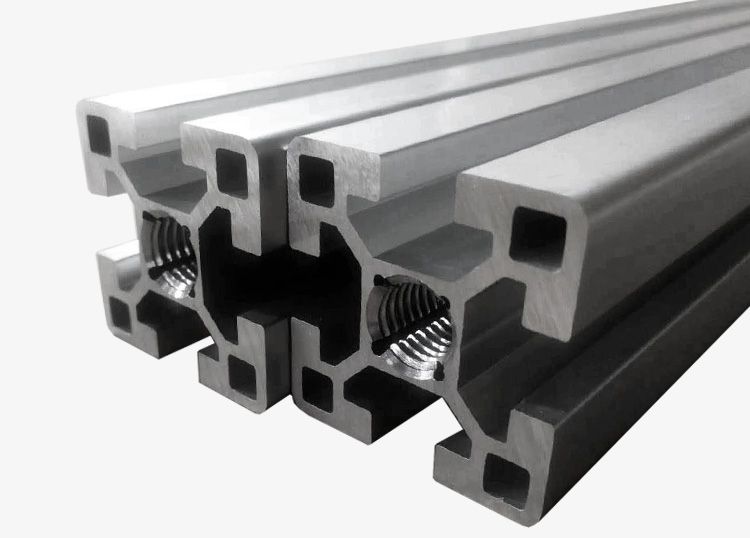

– T Slot Aluminium Extrusion

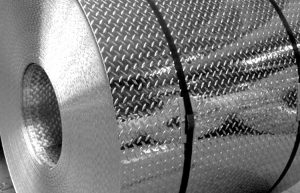

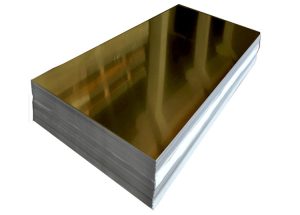

Aluminum Sheet/Plate/Foil

– Aluminum Plate

– Aluminum Sheet

– Aluminum Foil

– Aluminum Strip

– Aluminum Circle Disc

– Aluminum Coil

Finished Aluminum Products

– Aluminum Door

– Aluminum Window

– Aluminum Swing Gate

– Aluminum Handrail

– Aluminum Railing

– Aluminum Fence

– Aluminum Operation DeskTable

– Aluminum Louver

– Aluminum Goods Shelves

– Aluminum Ceiling System

Products

Service and Solutions

As your industrial partner, CHAL is committed to delivering the best quality to our customers, and meeting the key standards of the markets we operate in.

we offer manufacturing, machining, packaging, assembly of complete products and logistics, as well as after-service and support.

Manufacturing

Assembly of complete products and logistics

Machining

Transport

Packaging

After-Service and Support

News

A Guide to Aluminum MIG Welding Wire Selection and Application

How 6061 T6 Rectangular Tube Powers the New Energy Revolution?

Why Are Tapered Aluminum Tubes a Preferred Choice for Outdoor Equipment Applications?

How to Select Aluminum Sheet Thickness and Alloy for Architectural Applications

What’s Powering the Aluminum Phone Case Boom? A Look from Consumers to Manufacturers

Choosing Aluminium Square Tube Thickness? 5 Things You Must Know Before You Buy

Quality Management

CHAL is committed to delivering the best quality to our customers, and meeting the key standards of the markets we operate in.CHAL has been assessed and certified IATF16949, ISO9001 certificates of the quality management system and passed environmental management system ISO14001 and hazardous substances process management QC080000. Some of our products have been granted CE and other certificates issued by CCS and SGS.