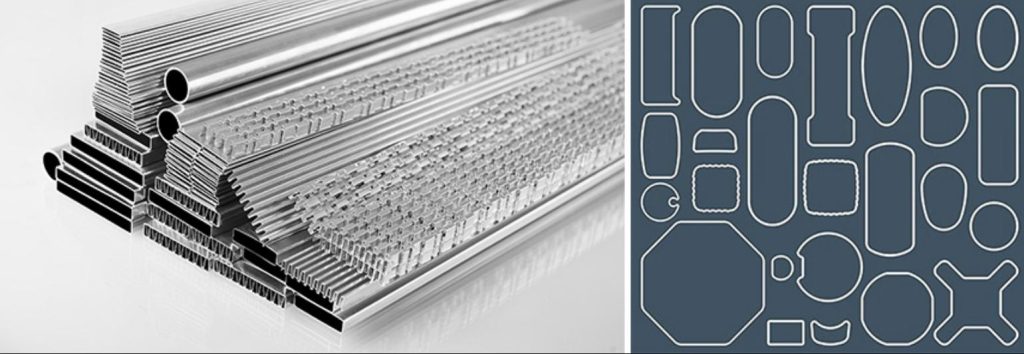

Both extruded aluminum tubes and seamless aluminum tubes are high-quality aluminum machining parts. They have a similar appearance, so people are often unable to tell them apart. So what is stretched aluminum tube? What is a seamless aluminum tube? How are they different?

What is extruded aluminum tube?

Most aluminum tubes on the market are produced by conventional combined die welding and extrusion process, which cannot completely avoid welding lines, especially dark lines after oxidation. Such aluminium tubes are called extruded aluminum tubes.

The extruded aluminium tube is made of aluminum short round rods through a high temperature and slow extrusion process. In the process of manufacturing extruded aluminum tubes, the mold should be kept clean, and the aging time and temperature should be adjusted appropriately according to the thickness of the tube wall and the size of each tube diameter.

What is seamless aluminum tube?

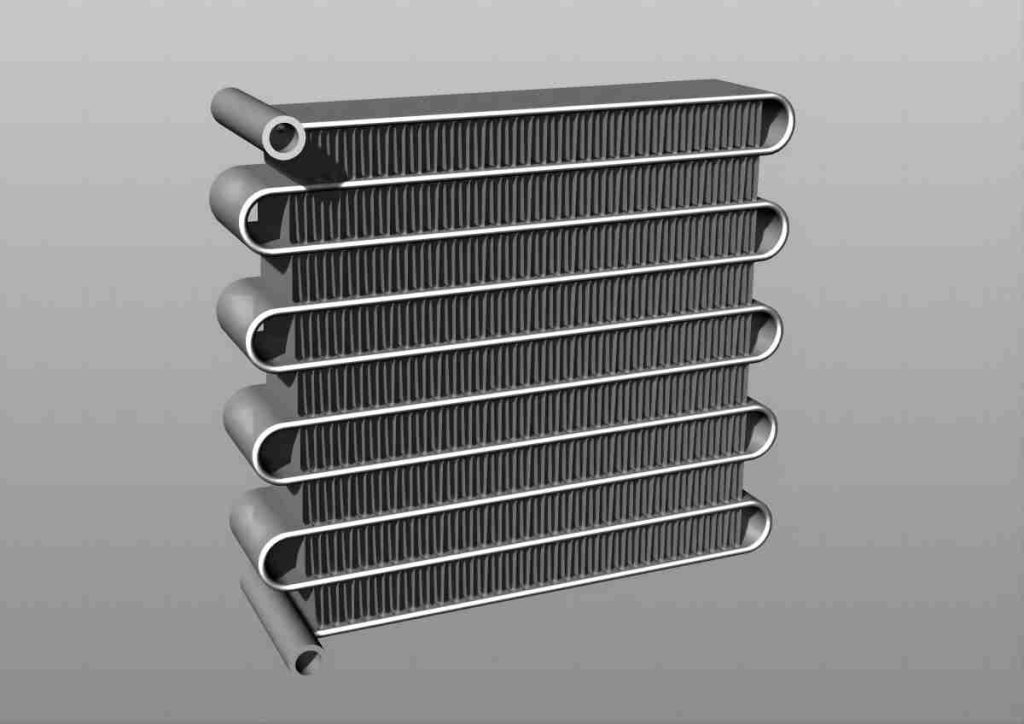

The seamless aluminum pipe generally adopts the perforation extrusion method, because the seamless aluminium pipe has the characteristics of small specific gravity, easy processing, and high mechanical strength.

The production process requirements of seamless aluminum tubes are relatively strict and fine. However, some problems should be paid attention to in the production process to produce high-quality seamless aluminium tubes.

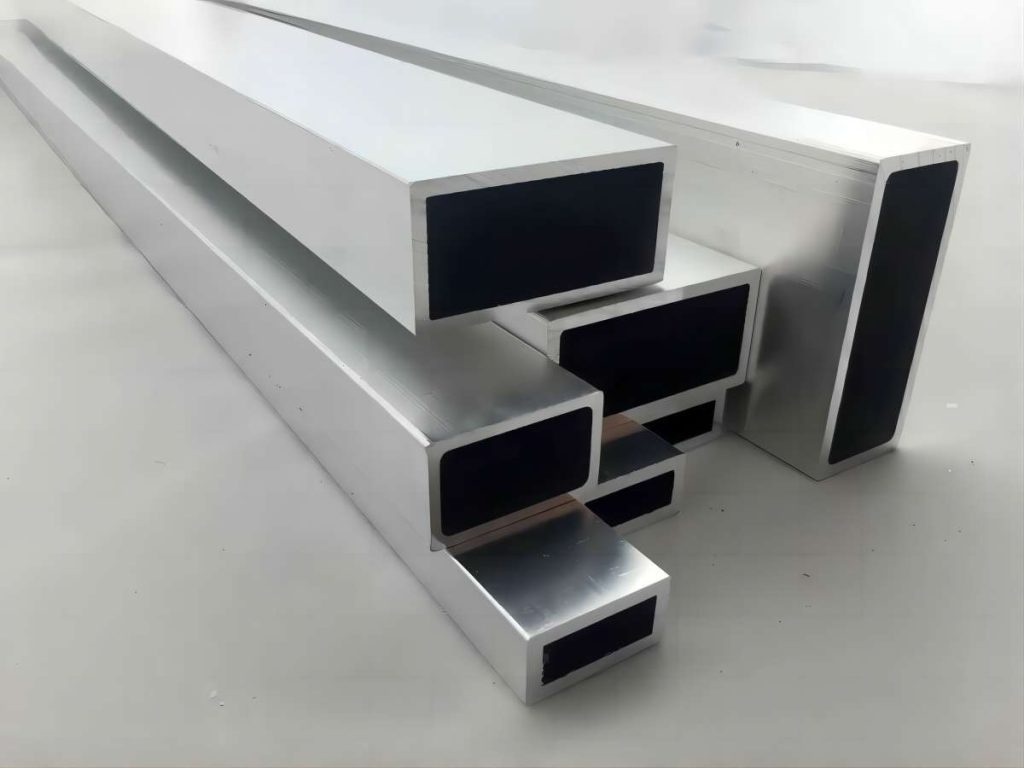

Seamless Aluminum Tube VS Extruded Aluminum Tube

During the extrusion process of the aluminum rod, the aluminum rod is in a state of strong pressure in the extrusion deformation zone, which can give full play to its plasticity and obtain a large amount of deformation. At the same time, extrusion deformation can improve the microstructure and mechanical properties of aluminium rods.

Especially for the aluminum rod with extrusion effect, after quenching and aging treatment, the longitudinal (extrusion direction) mechanical properties of the extruded product are much higher than those of similar products produced by other processing methods.

Seamless aluminum tubes are generally made by perforation extrusion. Due to their easy processing and high mechanical strength, seamless aluminum tubes are favored by aluminium tube users.

The production process requirements of seamless aluminum tubes are more stringent than those of drawn aluminum tubes. Therefore, some problems should be paid attention to during production to produce high-quality seamless aluminium tubes.

Large seamless aluminum tubes are generally hot extruded and then subjected to subsequent effective treatment. The small seamless aluminum tube can be hot extruded or cold drawn and then subjected to subsequent effective treatment.

The alumina hydrate produced in the production process of the seamless aluminium tube needs continuous extrusion, and the violent dehydration of the aluminum tube during the extrusion process is easy to form small holes on the surface of the aluminum tube. To prevent the generation of small holes on the seamless aluminum tube, we need to pay attention to:

- The round aluminum rod itself must not have rolling cracks;

- The aluminum tube shall not be stored in a humid environment;

- The sodium hydroxide content in the cleaning solution should be about 30%, and the aluminium ion content in the cleaning solution should be strictly controlled.

In general, extruded aluminum pipes have stronger economic value, but seamless aluminum pipes have stronger physical properties, and the physical properties of seamless aluminum pipes are better, and the processing requirements for seamless aluminium pipes are also will be higher.