Aluminum coils are fundamental materials in many industries, offering a combination of strength, durability, and versatility. Among the various types of aluminum coils, painted aluminum coils and color coated aluminum coils stand out for their aesthetic appeal and protective qualities. Despite their similarities, these two materials differ significantly in terms of production processes, appearance, and applications. This article delves into the distinctions between painted aluminum coil and color coated aluminum coil, explores their respective production methods, and highlights their suitability for different applications.

What is the Painted Aluminum Coil?

Painted aluminum coil is a type of aluminum material that has undergone a printing process to add patterns or colors directly onto its surface. The process involves several key steps, beginning with the pre-treatment of the aluminum coil. Pre-treatment typically includes cleaning and chemical treatment to enhance the coil’s surface adhesion and corrosion resistance. Once pre-treated, the coil is ready for the printing phase.

The printing process involves transferring a pre-designed pattern or color onto the aluminum surface using high-precision printing equipment, such as lithographic printers or digital inkjet printers. The choice of printing technology depends on the complexity and detail of the desired pattern. After printing, the aluminum coil undergoes curing at high temperatures to ensure that the printed design adheres firmly to the surface, forming a protective layer that enhances both durability and appearance.

Characteristics of Painted Aluminum Coil

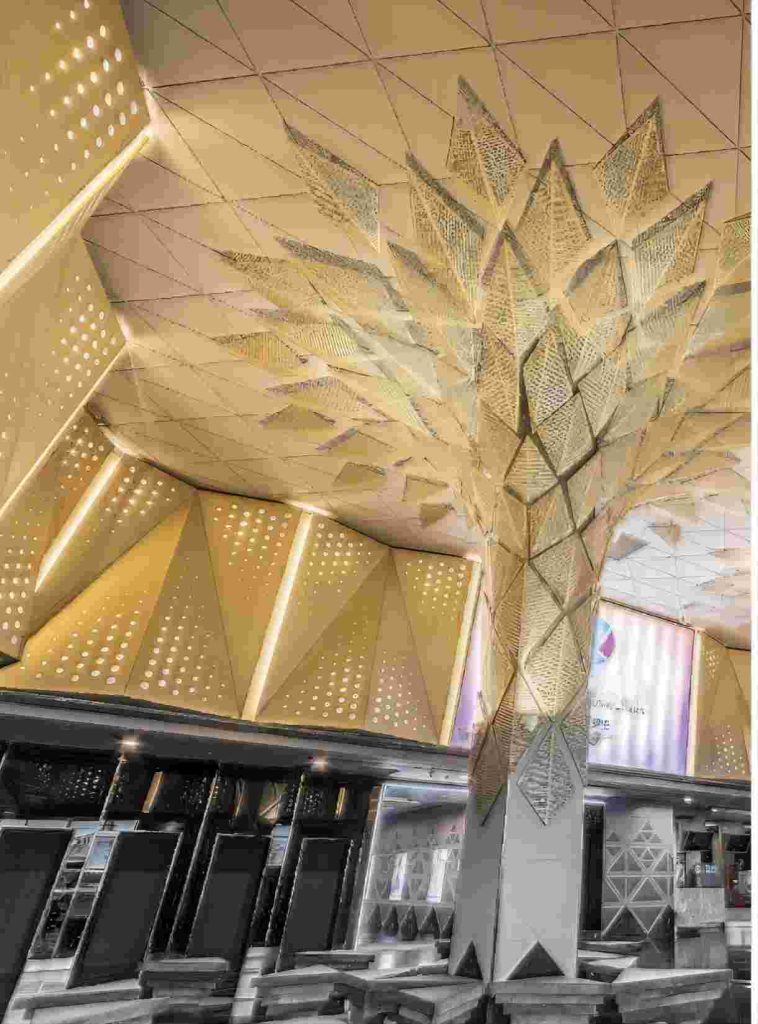

Painted aluminum coil is renowned for its rich variety of patterns and colors, making it a favorite in applications requiring intricate designs and aesthetic customization. This material allows for the creation of complex patterns, including wood grain, stone textures, and abstract art, providing architects and designers with the freedom to achieve unique and personalized visual effects.

One of the key advantages of a painted aluminum coil is its ability to replicate natural materials, such as wood and stone, with remarkable accuracy. This feature makes it an ideal choice for applications where a specific look is desired without the associated costs or maintenance requirements of the original materials. Additionally, the high-definition printing process ensures that the patterns are sharp, detailed, and resistant to fading over time.

What is the Color Coated Aluminum Coil?

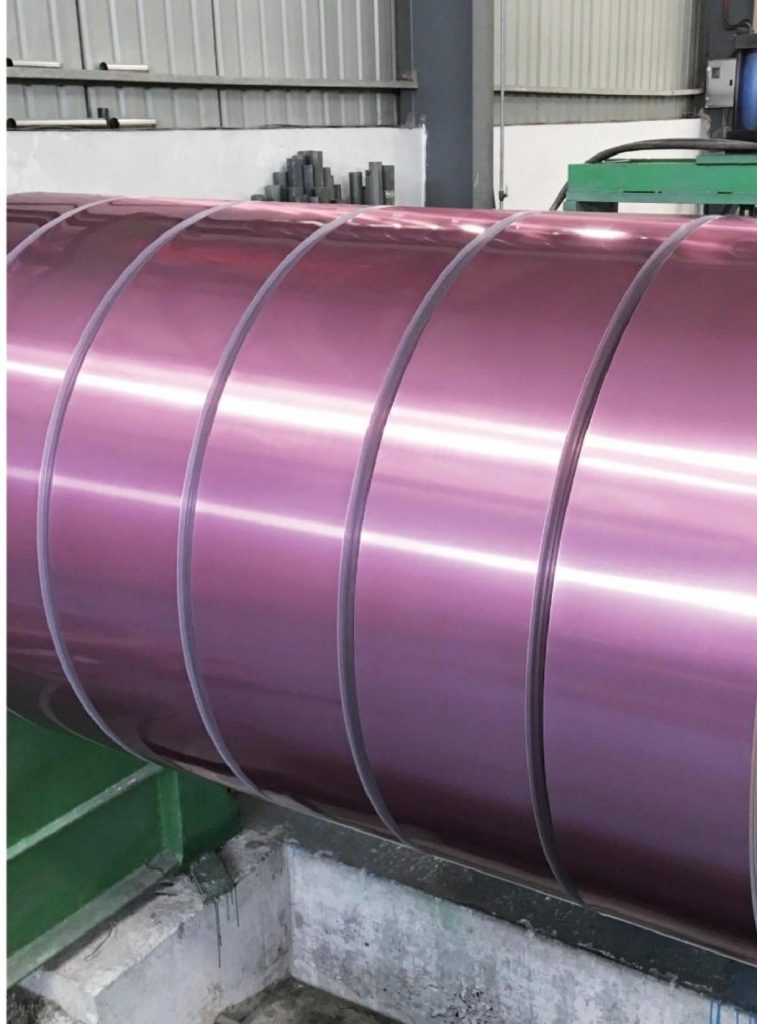

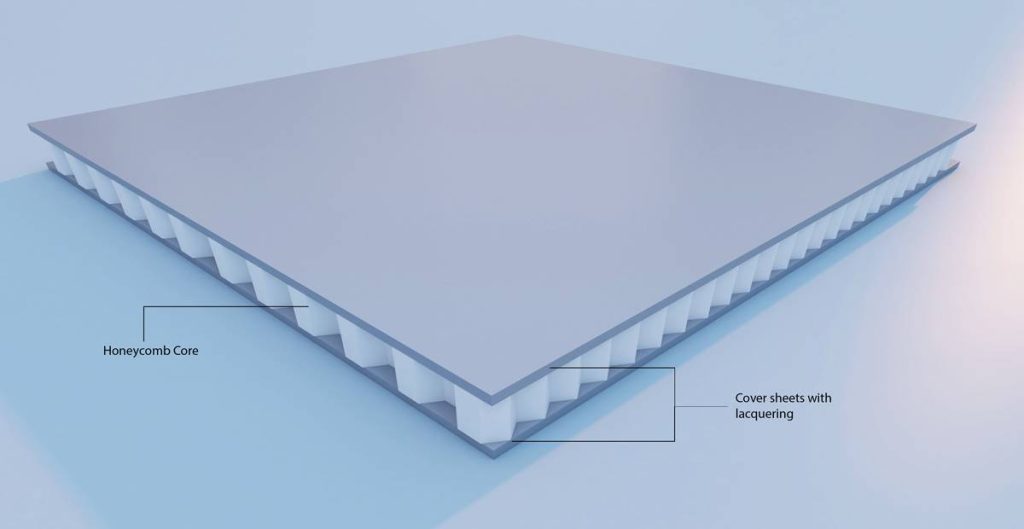

Color coated aluminum coil, on the other hand, refers to aluminum material that has been coated with a layer of liquid paint, which is then baked and cured to form a durable film. This process begins with the application of a liquid coating, which is evenly spread across the surface of the pre-treated aluminum coil. The coating is typically applied using roller coating or spray coating techniques, ensuring uniform coverage.

Once the coating is applied, the aluminum coil is passed through an oven where the coating is baked at high temperatures. This baking process causes the coating to cure, forming a hard, protective film that adheres strongly to the aluminum surface. The choice of coating material is crucial, with common options including polyester, fluorocarbon, and silicone-modified polyester, each offering different levels of weather resistance, corrosion protection, and color stability.

Characteristics of Color Coated Aluminum Coil

Color coated aluminum coil is valued for its excellent resistance to environmental factors such as UV radiation, moisture, and corrosion. The coatings used in this process are specifically formulated to withstand harsh outdoor conditions, making color coated aluminum coil an ideal choice for applications exposed to the elements.

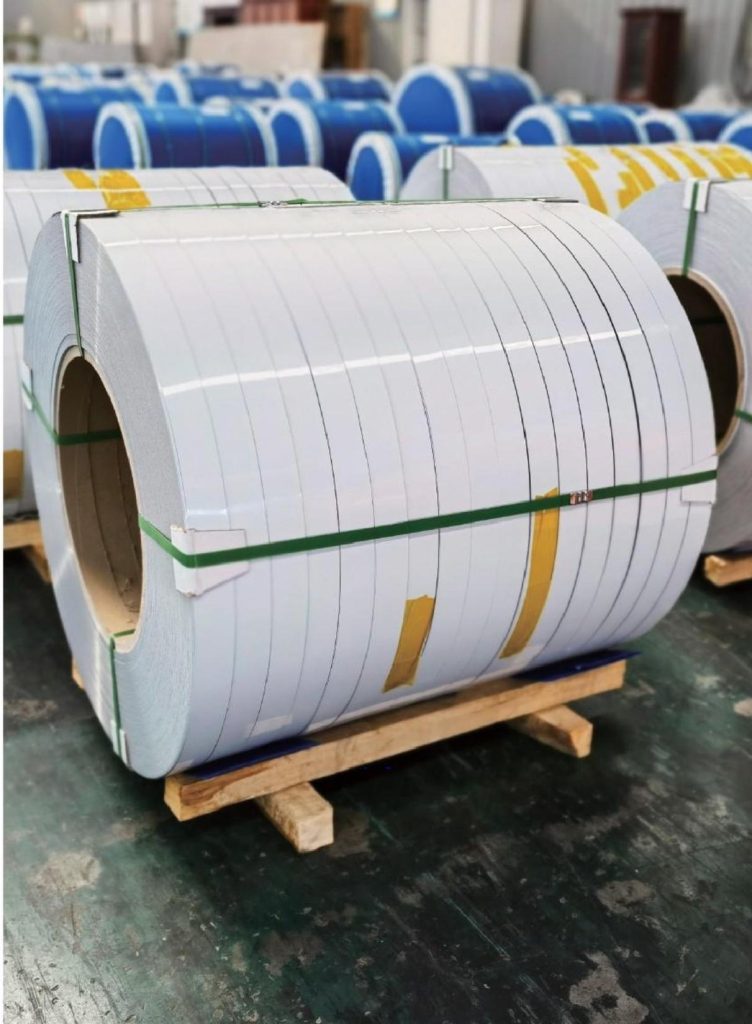

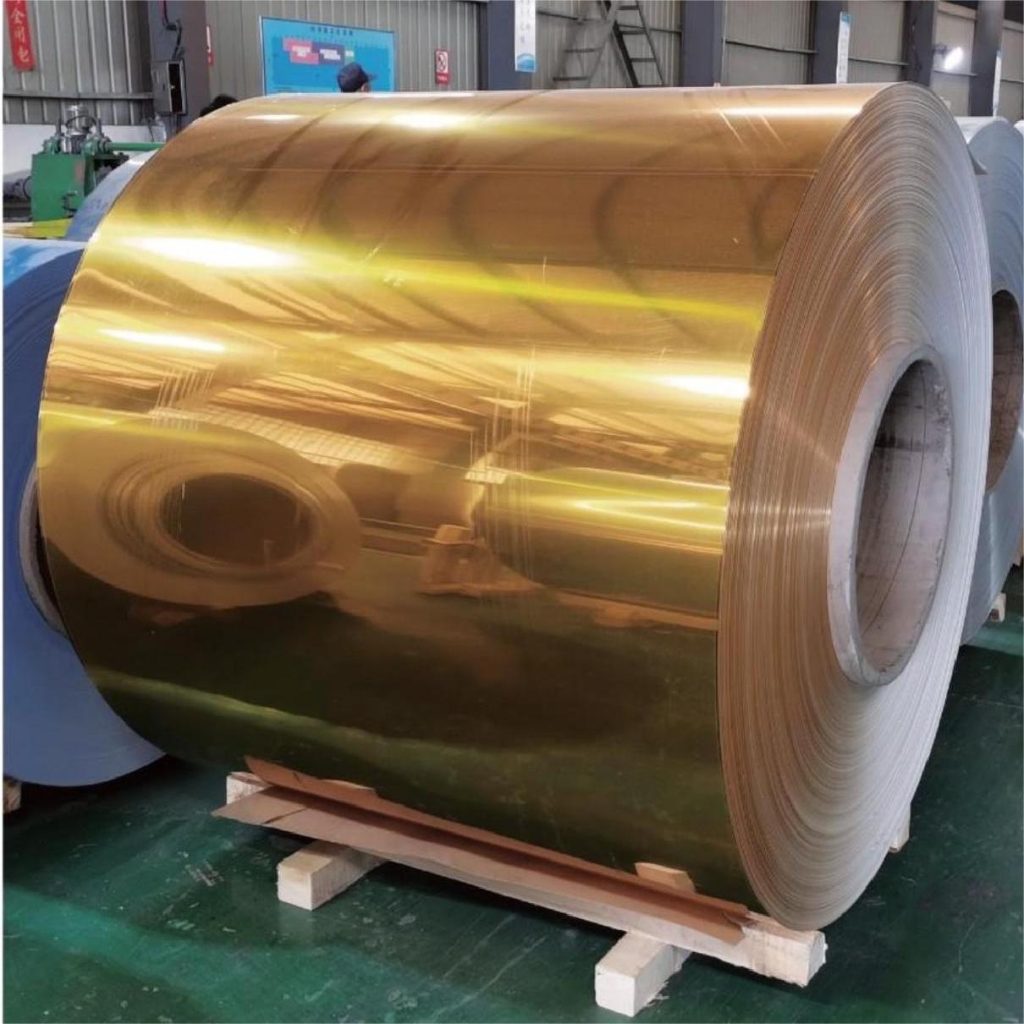

Unlike painted aluminum coil, which is known for its variety of patterns, color coated aluminum coil is typically produced in solid colors or metallic finishes. While the color options may be more limited, the emphasis is on color stability and longevity. The color coated aluminum coil’s uniform appearance is designed to remain vibrant and consistent, even after years of exposure to sunlight, rain, and temperature fluctuations.

Key Differences Between Painted Aluminum Coil and Color Coated Aluminum Coil

While both painted and color coated aluminum coils are used for their aesthetic and protective properties, they differ in several key aspects. Here are the detailed differences between these two types of aluminum coils as follows:

1. Differences in the Production Process

The production processes of painted aluminum coil and color coated aluminum coil differ significantly, each tailored to achieve specific outcomes that align with their intended applications.

Painted Aluminum Coil

- Printing Process: High-precision printing is used to apply patterns or colors directly onto the aluminum surface. This process involves advanced equipment such as lithographic or digital inkjet printers.

- Pre-Treatment: The aluminum coil undergoes a series of pre-treatment steps, including cleaning and chemical treatment, to enhance adhesion and corrosion resistance.

- Curing: After printing, the aluminum coil is cured at high temperatures to ensure the printed design adheres firmly and forms a durable protective layer.

Color Coated Aluminum Coil

- Coating Application: A liquid paint coating is evenly applied to the pre-treated aluminum surface using roller or spray coating techniques.

- Baking and Curing: The coated aluminum coil is baked at high temperatures, which cures the coating and forms a hard, protective film that adheres strongly to the surface.

- Coating Selection: The coating material is carefully chosen based on the required level of weather resistance, with options including polyester, fluorocarbon, and silicone-modified polyester.

2. Differences in Appearance

The appearance of painted aluminum coils and color coated aluminum coils reflects the different priorities of their production processes, resulting in distinct visual characteristics.

Painted Aluminum Coil

- Variety of Patterns: Offers a wide range of patterns and designs, including wood grain, stone textures, and abstract art, allowing for high levels of customization and artistic expression.

- Complexity and Detail: Capable of replicating intricate and detailed designs with high-definition printing, making it ideal for applications requiring a personalized aesthetic.

- Rich Artistic Effects: The printed designs are sharp, vibrant, and resistant to fading, ensuring long-lasting visual appeal.

Color Coated Aluminum Coil

- Solid Colors and Metallic Finishes: Typically features solid color options or metallic finishes, focusing on color stability and uniformity.

- Emphasis on Durability: The appearance is designed to remain consistent and vibrant over time, even under harsh outdoor conditions.

- Limited Color Variation: While the color options are fewer compared to painted aluminum, the material excels in maintaining its appearance without fading or discoloration.

3. Differences in Applications and Suitability

Painted Aluminum Coil

The unique characteristics of the painted aluminum coil make it highly suitable for indoor decorative applications and environments where artistic designs are desired. Some key areas of application include:

- Indoor Decoration: Used in high-end doors, windows, furniture panels, partitions, and exhibition displays, painted aluminum coil replicates natural materials like wood, adding elegance and allowing for personalized, visually appealing interiors.

- Advertising and Signage: Its ability to produce vibrant and complex designs makes it a popular choice for signs, billboards, and promotional materials, offering both customization and durability.

Color Coated Aluminum Coil

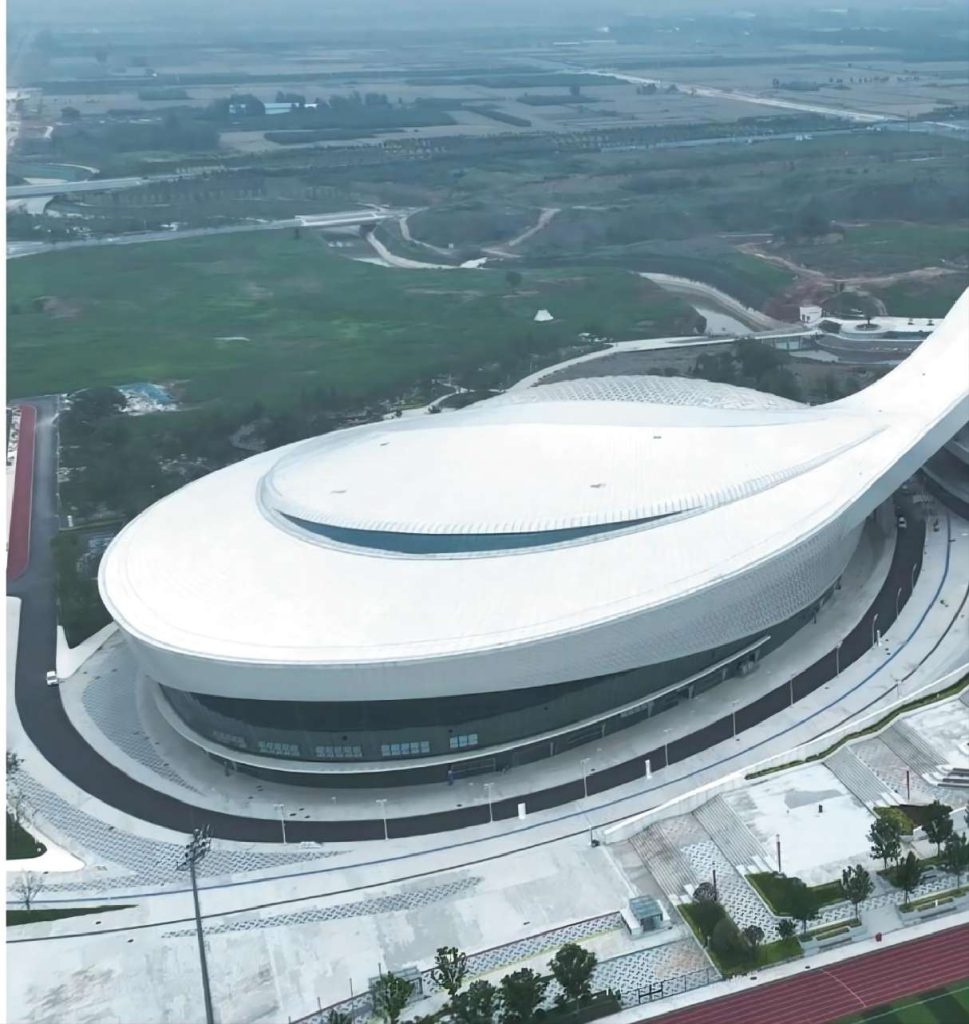

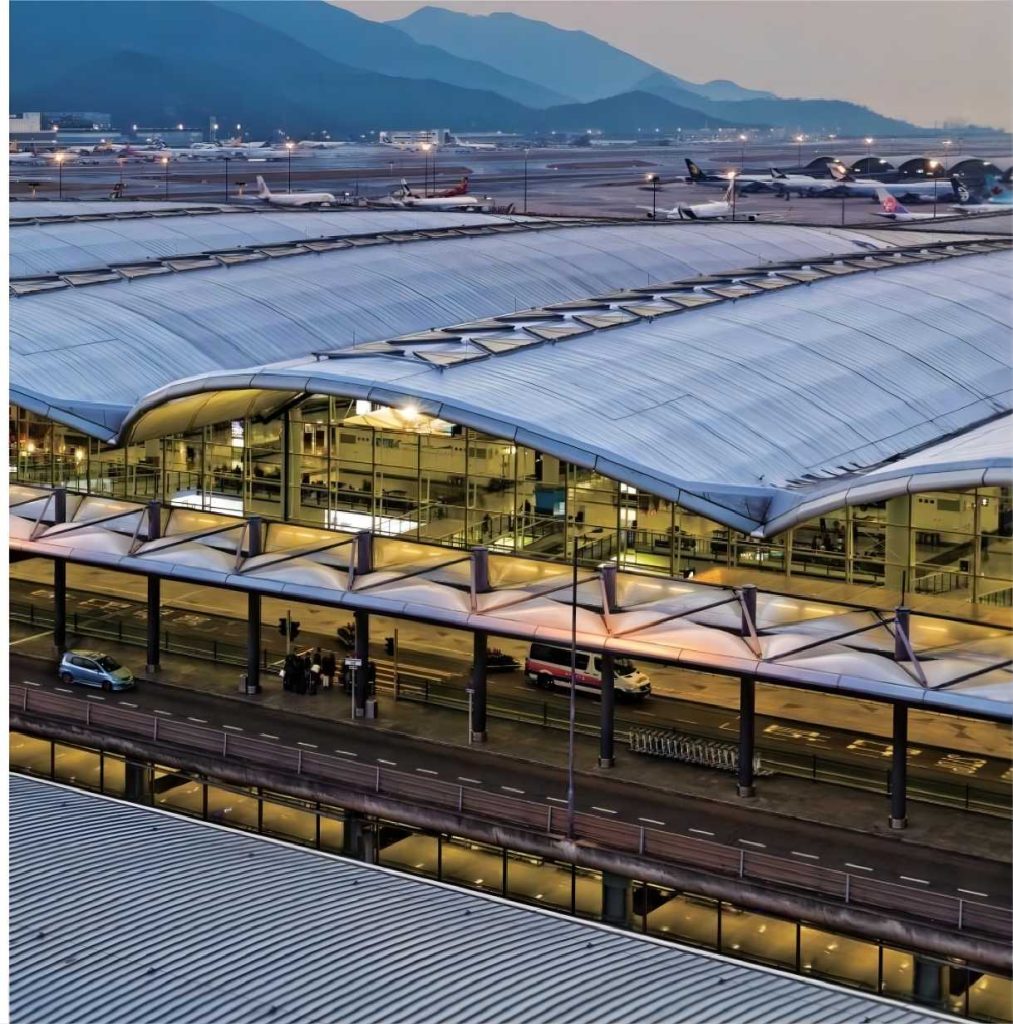

Color coated aluminum coil’s durability and weather resistance make it an excellent choice for outdoor applications, particularly in construction and industrial settings. Key applications include:

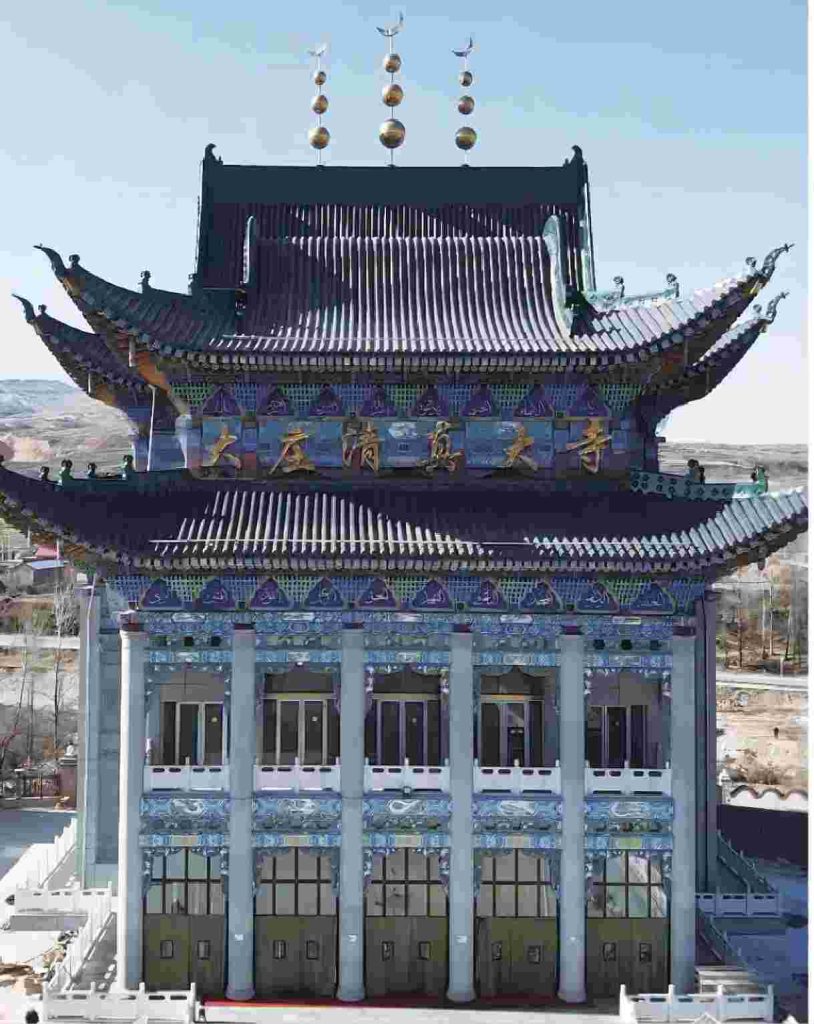

- Building Exterior Wall Panels: Ideal for facades of commercial buildings, residential complexes, and industrial facilities, it withstands harsh weather, maintaining its appearance and structural integrity over time.

- Roof Tiles: This material offers a durable, visually appealing solution for roofing, resisting sunlight, rain, and temperature fluctuations, and is available in various colors to meet aesthetic needs.

- Outdoor Industrial Products: It is used in air conditioner casings, vehicle panels, and other outdoor equipment due to its resistance to corrosion and fading, ensuring long-term functionality and attractiveness.

Anyway, painted aluminum coils and color coated aluminum coils aluminum coils each have their own advantages, and the choice of material mainly depends on specific application and design requirements.

If you are finding the color coated aluminum coils for construction use, and are interested in our products, please feel free to contact us, and we will return you as soon as possible.