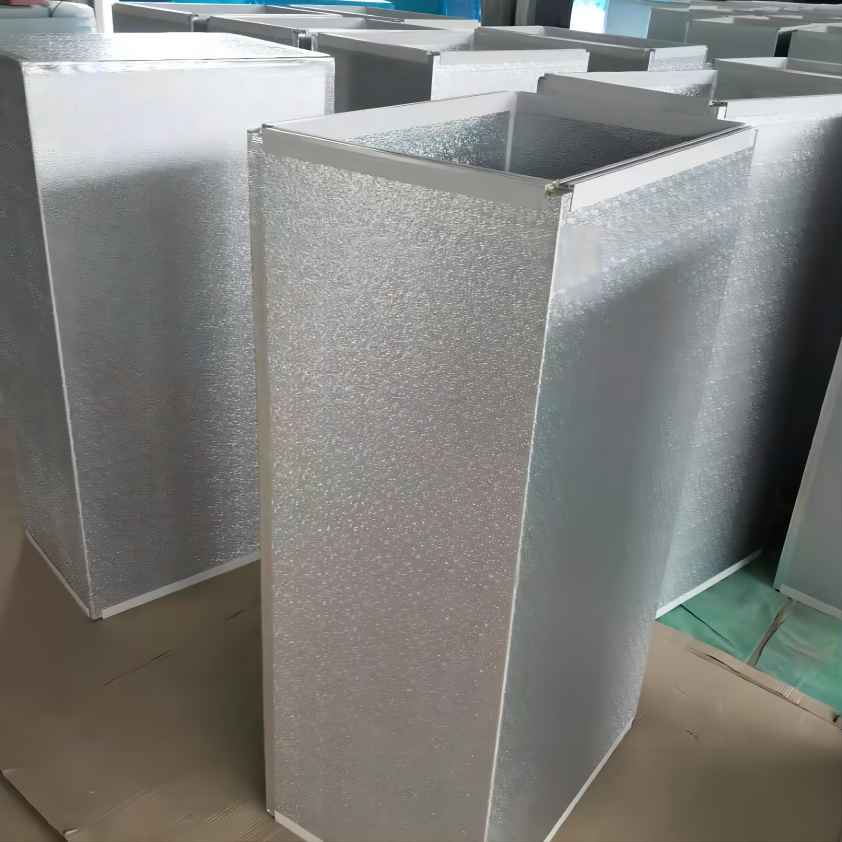

Aluminum honeycomb core is suitable for civil construction, vehicle, and boat decoration, etc. It is the application of aviation and aerospace materials in the field of civil construction. It is a kind of reprocessed product of aluminum foil.

How is aluminum honeycomb core made?

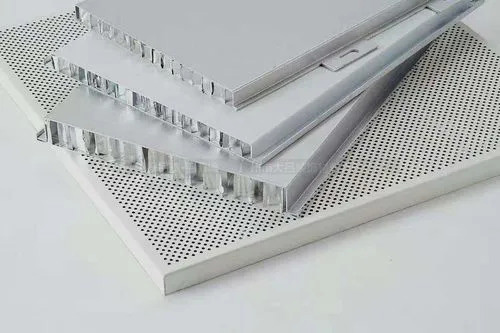

The entire processing process of aluminum honeycomb core is completed in a modern factory, using hot pressing technology. Due to the high thermal conductivity between the aluminum skin and the honeycomb, the thermal expansion and contraction of the inner and outer aluminum skins are synchronized; the honeycomb aluminum skin has small holes to make the plate The inner gas can flow freely; the slidable installation buckle system will not cause structural deformation during thermal expansion and contraction.

The panel of aluminum honeycomb core mainly uses a high-quality 3003H24 alloy aluminum plate or 5052AH14 high manganese alloy aluminum plate as the base material, and the thickness of the panel is 0.8~1.5mm fluorocarbon roll-coated plate or color-resistant baking paint. The color-resistant baking paint is resistant to scratches and acid rain corrosion. It is stronger than PVDF in terms of discoloration and self-cleaning, the thickness of the bottom plate is 0.6~1.0mm, and the total thickness is 25mm.

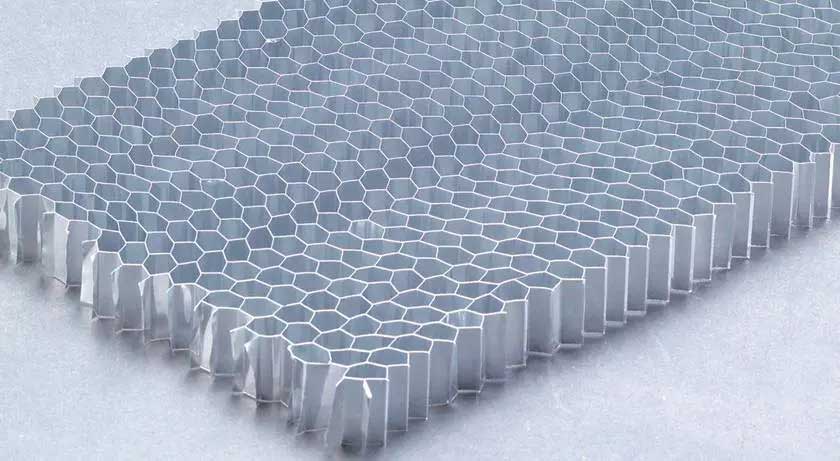

The core material of the aluminum honeycomb core adopts a hexagonal 3003 aluminum honeycomb core, the thickness of the aluminum foil is 0.04~0.06mm, and the side length is 5~6mm. The front and back skins are formed by roll forming technology. The back skin snaps tightly on the mounting side.

The entire processing process is completed in a modern factory, using hot pressing technology. Due to the high thermal conductivity between the aluminum skin and the honeycomb, the thermal expansion and contraction of the inner and outer aluminum skins are synchronized; the honeycomb aluminum skin has small holes so that the gas in the plate can be freely Flow; the slidable installation buckle system will not cause structural deformation during thermal expansion and contraction, so it can ensure extremely high flatness. Adhesive: two-component polyurethane high-temperature curing adhesive is used. Automatic honeycomb panel composite production equipment adding It is compounded by pressing and high temperature, which overcomes the brittleness problem of the previous honeycomb panel bonding layer.

Its inner layer is a special hexagonal aluminum honeycomb, made of aluminum alloy with a hardness of H19, which acts as a core plate adhered to the sandwich structure and is subjected to pressure in the tangential direction. These dense honeycombs restrained by each other are like many small I-beams, which can disperse the pressure from the direction of the panel, so that the panel is evenly stressed, ensuring that the panel can still maintain a high flatness in a large area.

What’s so special about aluminium foil made honeycomb core?

The center is an aluminum hexagonal honeycomb with low density (about 3 to 7 kg per square meter). In the case of the same area, its weight is 1/5 of the weight of the board, 1/6 of the glass, and 1/7 of the aluminum, which greatly reduces the building load.

Since the middle interlayer of the aluminum honeycomb core contains a lot of air, the aluminum honeycomb core can be soundproof (the air sound insulation can reach 30dB) and heat insulation (the thermal resistance can reach 0.02(㎡·K/W)). And there is no flammable substance in the core, the fire rating reaches B1 level, waterproof, moisture-proof, no harmful gas release.

Where is aluminum foil made honeycomb core used?

As a processed product of aluminum foil, aluminum honeycomb cores are used in many fields. E.g:

(1) Building curtain wall panels

(2) Interior decoration engineering

(3) Billboards

(4) Shipbuilding

(5) Aviation manufacturing

(6) Indoor partition and commodity display stand

(7) Commercial transport vehicles and container bodies

(8) Buses, trains, subways, and rail vehicles

(9) For the modern furniture industry with strict environmental protection requirements, the use of aluminum honeycomb panels as furniture processing materials is a good material choice in the new century. Its completely non-toxic green quality enables furniture manufacturers to process furniture. In addition, aluminum honeycomb panels can be made of solid wood, aluminum panels, gypsum panels, natural marble, and other materials, and can be made into honeycomb panels, which are convenient for material selection.

At CHAL, our most frequent orders are from the construction and manufacturing industries. This is determined by the characteristics of the aluminum honeycomb core. However, since each customer has different requirements for the aluminum type and physical properties of aluminum honeycomb core, we will find suitable aluminum honeycomb core for customers according to their requirements. It is precisely because of this that our products have been well received by customers. If you are also looking for the right aluminum honeycomb core for you, please contact us via our homepage.