It is being frequently asked online for the question that if Aluminum Foil Roll have an expiration date, and the answers are various. Some of them think that the date would be one year, some think 3years, and others indicate that as a metal material, aluminum foil roll has no expiration date. Today let’s find out the real answer in this article.

Does Aluminum Foil Roll Have an Expiration on earth?

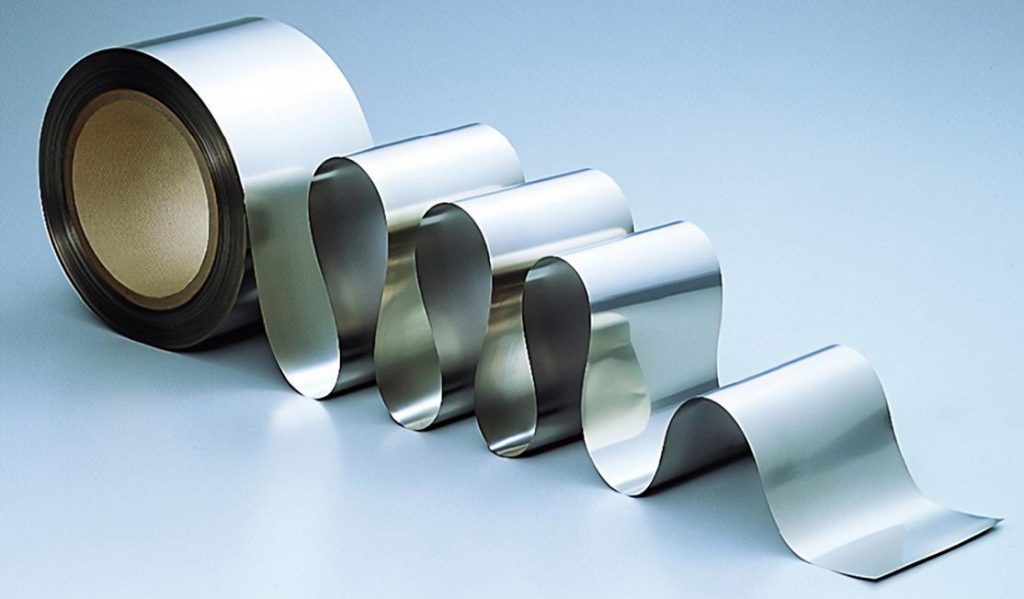

Aluminum foil roll is made of metal aluminum or aluminum alloy by rolling equipment. The thickness of the habit of 0.025mm is called aluminum foil. The thickness of the following 0.2mm is called aluminum foil. A thickness of more than 0.2mm is called an aluminum foil roll. The density of aluminum or aluminum foil is 2.70 g/cm3. The melting point is 660 ℃—the boiling point is 2327℃, the appearance of silver-white light metal, ductility, and ductility. In humid air, an oxide film can be formed to prevent metal corrosion. Theoretically, aluminum foil roll are metal materials with no shelf life.

Factors That Affect Aluminum Foil Roll Preservation

In practice, however, this is not practice, however, this is not always the case, as the reels must be carefully preserved; otherwise, they may become contaminated and become unsuitable packaging materials.

Many people think that aluminum foil roll have a shelf life because they are usually processed into a variety of aluminum foil bags and containers coated with ink, paint, and other materials. These paint materials are likely to be contaminated and damaged in storage, thus further affecting the service life of the entire bag or container. Nevertheless, aluminum foil is still the most suitable barrier material for air-conditioned packaging. The combination of aluminum foil with PVDC and EVOH film will bring revolutionary progress for food preservation technology. With high-temperature resistance, low-temperature resistance, puncture resistance, and other characteristics, to ensure the taste of food, nutrition, and freshness at the same time, prolong the shelf life. It can withstand temperatures ranging from 180 degrees to minus 180 degrees.

Metal material, high-grade appearance, low cost, high efficiency. environmentally it has metal material, a high-grade appearance, low cost, high efficiency. Environmentally friendly and recyclable, cartons and aluminum foil rolls are 100% recyclable, EVOH film can be decomposed into carbon dioxide and water.

Applications of aluminum foil roll

Aluminum foil for insulation and vapor barrier used in the construction industry

One of the most important applications of aluminum foil is insulation. For example, it is used as an insulating layer for pipe and pipe insulation.

In the construction industry, aluminum foil is also used as the top layer of insulation materials such as rock wool, foam insulation board, and layered pad in building insulation. Acting as a vapor barrier, the film ensures that no water vapor penetrates the insulation, thus preventing mold formation and moisture damage.

Aluminum foil for insulation of cables

Due to its lightweight and high conductivity, aluminum foil is ideal for the insulation of power cables. This is particularly important for heavy voltage cables. Not only can it improve electromagnetic compatibility, but it can also be used to locate damage.

In addition, aluminum provides a degree of protection against electric shocks caused by cable damage. The insulation of aluminum foil also protects cables from moisture and reduces interference from electronic devices in communication cables.

Aluminum Foil As the Basis for Aluminum Tape

Aluminum tape is a thin aluminum foil coated with a heat-resistant adhesive on one side. Compared with plastic tape, aluminum tape has the advantage of high heat resistance. It does not become brittle by heat or cold, making it more durable than plastic tape.

Aluminum Foil in the Packaging Industry

The rise of aluminum foil in the packaging industry began as early as the early 20th century. As early as 1910, aluminum foil up to 10 μ s (1/100 mm) thick could be produced and laminated with paper. Technological advances have led to rapid development, from the use of aluminum for chocolate packaging to the manufacture of aluminum beverage cans, coffee capsules, baking trays, and bottle caps.

Advantages of Aluminum Foil

- aluminum foil with shiny metallic luster, decorative;

- Non-toxic, tasteless, odorless;

- The weight is relatively light, the specific gravity is only one third of iron, copper, full stretch, thin, low weight per unit area; Good shading, reflective rate of 95%;

- Strong protection, so that the packaging is not susceptible to bacteria, fungi and insects;

- High and low temperature stability, temperature -73 ~ 371℃ does not deform shape;

- Excellent barrier performance, moisture-proof, air-tight, fragrance, prevent moisture absorption, oxidation and volatilization of the package of goods, moisture resistance, oxygen isolation performance.

- Aluminum foil, plastic film and paper, which are easy to process, can be compounded.

Why Choose CHAL?

If you want to know more about CHAL’s aluminum foil, please visit our homepage – CHAL to learn more. we have a professional team with decades of experience in producing aluminum foils, we can support you with the best aluminum foil from China.