Aluminum is a highly versatile and abundant metal, playing a pivotal role in various industries due to its unique combination of properties. Beyond its lightweight nature and corrosion resistance, its electrical properties stand out, making it an essential material for numerous electrical and industrial applications. As industries demand lighter, cost-effective, and efficient materials, aluminum’s role as a conductor has grown significantly. Here we explore the electrical properties of aluminum and the industrial applications that leverage its unique characteristics, while also discussing the challenges and recent advancements shaping its future.

Electrical Properties of Aluminum

Conductivity Characteristics

Aluminum has a conductivity of approximately 37.7 million Siemens per meter (MS/m) at room temperature, which is about 60% of copper’s conductivity. While it may seem inferior to copper in terms of sheer conductivity, aluminum compensates with its lightweight nature, having a density of only 2.7 g/cm³ compared to copper’s 8.96 g/cm³. This means that, weight-for-weight, aluminum provides almost twice the conductivity of copper, making it highly suitable for applications where weight reduction is critical.

For example, aluminum is extensively used in high-voltage transmission lines. In such cases, its ability to conduct electricity efficiently over long distances with minimal energy loss is critical. Additionally, the material’s high strength-to-weight ratio enables its use in overhead power lines without excessive structural support.

Factors Influencing Conductivity

The electrical conductivity of aluminum is not fixed and can be influenced by several factors:

- Purity: Higher purity aluminum exhibits better conductivity. Commercially pure aluminum (99.7%) is often used in electrical applications.

- Temperature: As with most metals, aluminum’s conductivity decreases as temperature increases. This is due to increased electron scattering at higher temperatures.

- Alloying Elements: Adding elements like magnesium or silicon to aluminum enhances its strength but often reduces its electrical conductivity. For instance, aluminum alloys used in structural applications may have conductivity as low as 30% of pure aluminum.

By understanding and optimizing these factors, industries can tailor aluminum to specific applications, balancing conductivity with other mechanical properties.

Advantages of Aluminum as a Conductor

Aluminum offers several advantages as a conductor:

- Lightweight: At one-third the weight of copper, aluminum is ideal for applications where reducing weight is crucial, such as in aerospace and automotive industries.

- Cost-Effectiveness: Aluminum is significantly cheaper than copper, both in raw material cost and overall installation expenses.

- Corrosion Resistance: The natural formation of a thin oxide layer on aluminum’s surface provides excellent resistance to corrosion, extending its service life in harsh environments.

The cost efficiency of aluminum, paired with its lightweight characteristic, make it a very attractive option for large scale electrical infrastructure.

Industrial Applications of Aluminum

Aluminum’s versatility in electrical applications is demonstrated by its use in various forms, including wires, cables, busbars, and foils.

Power Transmission:

Overhead power lines are a prime example of aluminum’s use. Aluminum conductors, often reinforced with steel (ACSR), are employed for long-distance transmission due to their lightweight and cost-effective properties. This reduces sag and the need for frequent support towers.

In substations, aluminum busbars, rigid electrical conductors, are used to distribute high currents.

Electrical Wiring:

Aluminum wiring is prevalent in building wiring, particularly in large commercial and industrial buildings. While some concerns about earlier forms of Aluminum house wiring exist, modern aluminum alloy wiring, with proper installation, is considered safe.

In the automotive industry, aluminum wiring harnesses are employed to reduce vehicle weight and improve fuel efficiency.

Electronics:

Aluminum electrolytic capacitors, vital components in electronic circuits, utilize aluminum foil as electrodes. Aluminum heat sinks are used to dissipate heat from electronic devices, ensuring their proper operation. Aluminum is used in the creation of printed circuit boards, and other sensitive electrical equipment.

Transportation:

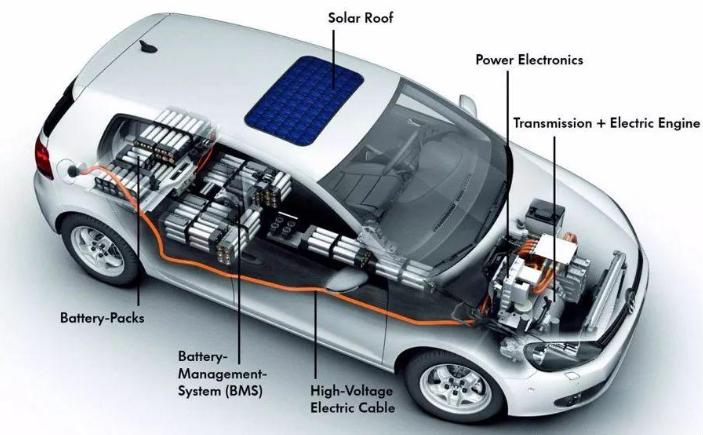

The rise of electric vehicles (EVs) has spurred increased demand for aluminum in battery connections and wiring harnesses. In aircraft electrical systems, aluminum’s lightweight nature is indispensable for optimizing fuel efficiency.

The wide variety of applications showcases aluminums versatility, adaptability and efficiency in modern industry.

Challenges and Advancements

Despite its advantages, aluminum faces challenges in certain applications. Its lower conductivity compared to copper necessitates larger cross-sectional areas for equivalent current-carrying capacity. Also, aluminum’s susceptibility to oxidation can create connection issues, requiring specialized connectors and installation techniques. Recent advancements have focused on developing high-conductivity aluminum alloys, improved connection technologies, and advanced insulation materials.

Researchers continue to investigate new alloying techniques and surface treatments to enhance aluminum’s performance and address its limitations. In addition, the growing emphasis on renewable energy systems is driving the development of aluminum-based solutions for solar panels and wind turbines. The smart grid also depends on enhanced aluminum wiring and infrastructure.

Aluminum’s electrical properties, notably its commendable conductivity and lightweight nature, have propelled it into a vital role in diverse industrial applications. From power transmission and electrical wiring to electronics and transportation, aluminum’s versatility continues to be invaluable. Although challenges remain, ongoing research and development are paving the way for improved performance and expanded applications. As the demand for efficient and sustainable electrical solutions grows, aluminum is poised to remain a key player in the electrical industry.