Aluminium channels are versatile structural components that find application across a wide range of industries due to their strength, durability, and corrosion-resistant properties. These channels come in various shapes and designs, each tailored to specific purposes. In this article, we will delve into the world of aluminium channels, exploring their types and applications.

Aluminium U-Channel: A Strong Foundation

The aluminium U-channel is a popular choice in construction and engineering. With its U-shaped profile featuring a closed top and open bottom, the U-channel offers exceptional strength, making it ideal for applications requiring structural support and framing. This design helps distribute weight evenly along the base, making it effective in various load-bearing scenarios. Additionally, its open bottom allows easy routing of cables or pipes, making it a common choice in electrical installations.

Industries such as architecture, manufacturing, and automotive rely on aluminium U-channels for tasks ranging from framework construction to machinery reinforcement. It’s the go-to choice when stability and sturdiness are paramount.

Aluminium C-Channel: Versatility in Form

The aluminium C-channel derives its name from its distinctive C-shaped profile featuring an open top and bottom. This form grants it a high degree of versatility, making it suitable for numerous applications. Due to its shape, the aluminium C-channel is often used for shelving systems, acting as a robust support structure. It’s also a common component in siding, where it helps secure and stabilize panels.

In the realm of construction, aluminium C-channels find their place in framework assembly, offering a reliable backbone for various structures. They also play a role in the creation of gutters, ensuring efficient drainage systems. The adaptability of aluminium C-channels makes them a valuable resource in industries requiring adaptable solutions.

Aluminium J-Channel: Precision and Protection

The aluminium J-channel showcases a unique design with one leg perpendicular to the base and the other angled at 45 degrees. This distinctive form makes it ideal for applications demanding precision, such as window and door trim. It provides a secure housing for the edges of the siding material, offering both protection and aesthetic appeal.

Furthermore, aluminium J-channels are employed as flashing in construction projects, preventing water infiltration around openings like windows and doors. Its ability to redirect water away from vulnerable areas makes it an invaluable asset in maintaining structural integrity.

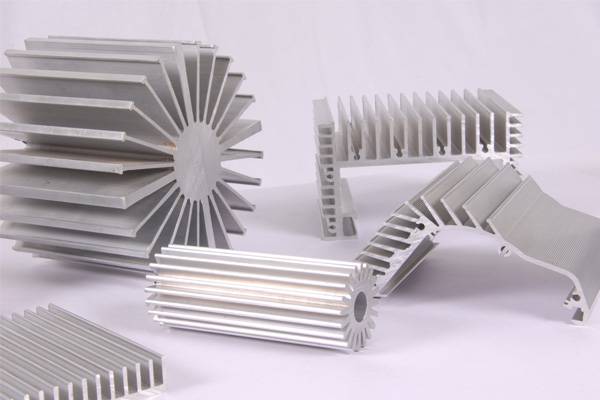

Aluminium Hat Channel: Curved for Performance

Aluminium hat channels feature a flat top and curved sides, resembling the profile of a hat. This design grants it an exceptional combination of strength and flexibility. Aluminium hat channels are often utilized in roofing applications, providing structural support while allowing for thermal expansion and contraction. The curved sides enhance load-bearing capacity, making them a reliable choice in heavy-duty scenarios.

In addition to roofing, hat channels find their way into siding projects, signage, and other applications where durability is crucial. Their unique shape contributes to effective weight distribution and resilience in demanding conditions.

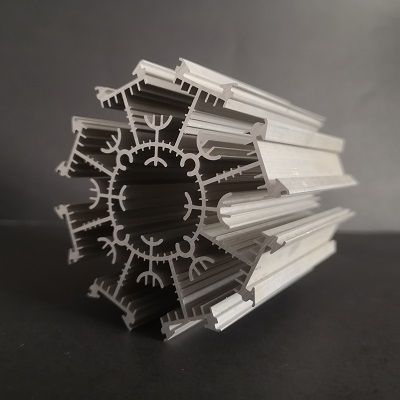

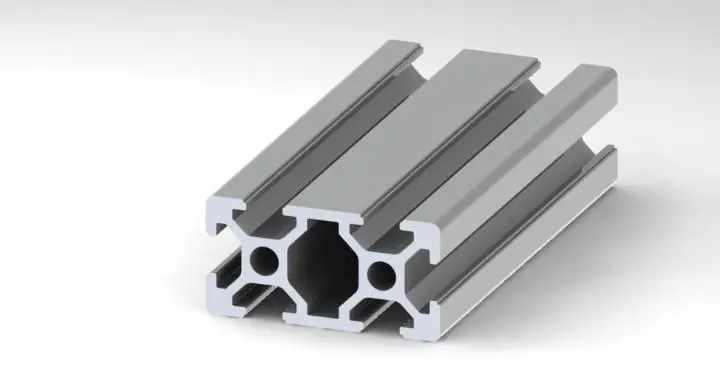

Aluminium T-Slot Channel: Customization and Flexibility

T-slot channels aluminium are recognized by the T-shaped slot in their tops, offering a unique advantage: the ability to attach components and accessories along the channel’s length. This design enables easy customization, making them popular for various industrial uses. They are commonly employed in manufacturing environments for creating mounting brackets, fixtures, and workstations.

The T-slot design facilitates the integration of additional hardware, allowing for the creation of versatile and adaptable systems. Industries ranging from electronics to automotive benefit from the flexibility offered by T-slot channels.

In conclusion, aluminium channels play a pivotal role in diverse industries due to their wide range of shapes and designs. From U-channels providing stability in construction to J-channels ensuring precision in architectural trim, these versatile components are indispensable in modern engineering. Whether it’s the adaptability of C-channels or the strength of hat channels, each type serves a specific purpose, contributing to the foundation of countless structures and systems. As industries continue to evolve, aluminium channels will undoubtedly remain at the forefront of innovation and design.