We all know that there are many kinds of aluminum sheets on the market now. The aluminum panels generally used in walls are mainly fluorocarbon aluminum panels, which are also the most common aluminum veneer products in our daily life. But in fact, another kind of aluminum plate that is also very popular in the market is polyester aluminum plate. Its main application place is the decoration of indoor walls. So, what is the difference between a fluorocarbon aluminum sheet and a polyester aluminum sheet?

What is a polyester aluminum sheet?

The polyester aluminum sheet is a common type of plastic sheet, which is used in a wide range of and is applied in various industries. For example, our kitchen ceiling and toilet ceiling are made of lightweight plastic panels. This type of panel has many advantages, such as lightweight, wear resistance, high-temperature resistance, dirt resistance, etc., and the polyester aluminum veneer is one of them. types.

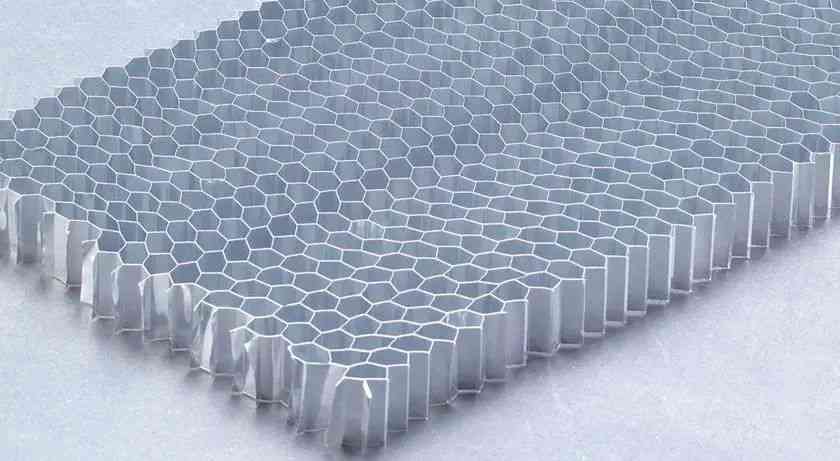

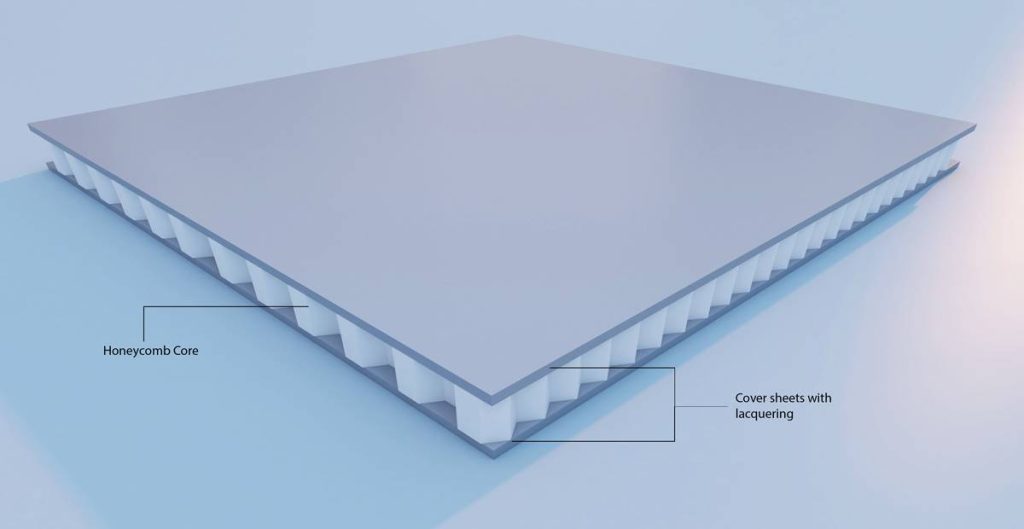

Sheet polyester aluminum veneer is a composite material processed on special polyester aluminum veneer production equipment with the chemically treated coated aluminum plate as the surface material and polyethylene plastic as the core material. The unique properties of the polyester aluminum veneer itself determine its wide application.

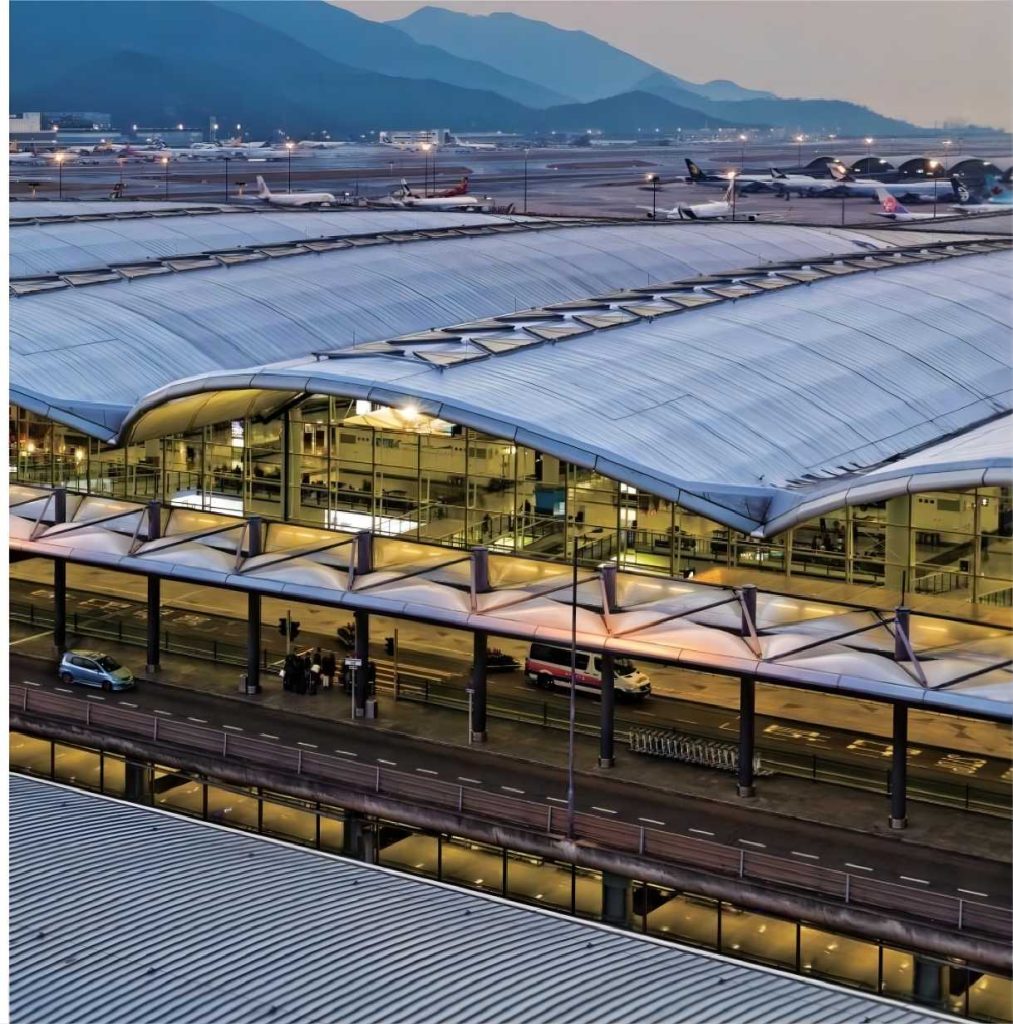

It can be used for building exterior walls, curtain wall panels, renovation of old buildings, interior wall and ceiling decoration, advertising signs, display stands, and purification and dust-proof projects. It belongs to a new type of building decoration material.

As a new type of decorative material, the polyester aluminum plate is quickly favored by people for its economy, variety of optional colors, convenient construction methods, excellent processing performance, excellent fire resistance, and noble quality.

What is fluorocarbon aluminum sheet?

The fluorocarbon aluminum plate is made of high-grade aluminum alloy as the main material, which is refined by various processes such as molding and molding, and then sprayed with PPG or Akzo paint on the surface.

The surface of the fluorocarbon aluminum curtain wall system is flat and smooth, with good wind pressure resistance and a variety of color coatings to choose from, which makes the building convey a distinctive modern feeling. The design of the system is reasonable, can meet the needs of various functions, and is widely used in the wall decoration of various commercial or industrial buildings.

To put it simply, fluorocarbon aluminum veneer is an ordinary aluminum veneer sprayed with fluorocarbon paint, corresponding to polyester aluminum veneer, or powder aluminum veneer.

Fluorocarbon aluminum panels are manufactured using high-quality aluminum alloy panel substrates, which are bent by numerical control technology, which can ensure that the fluorocarbon aluminum veneers remain flat and undeformed during installation and use. Sometimes it can have a better ability to resist pressure, and most of them are used as exterior wall veneers in decoration. The thickness of the product is also relatively objective. It is not only durable but also has certain thermal insulation and sound insulation properties.

What is the difference between fluorocarbon aluminum sheet and polyester aluminum sheet?

The main difference between a polyester aluminum veneer and other aluminum veneers is that polyester aluminum veneer uses chemically treated coated aluminum as the surface material and polyethylene plastic as the core material, which is used for special polyester aluminum veneers.

The composite material processed on the production equipment and the unique properties of the polyester aluminum veneer itself determine its wide range of uses: it can be used for building exterior walls, curtain wall panels, renovation of old buildings, interior wall and ceiling decorations, advertising signs, display Racks, purification, and dust-proof projects, etc.

The spraying thickness of polyester aluminum plate products is generally around 50μm (micrometer). If it is used for interior decoration, the warranty period can reach about 10 years, but if it is used for exterior wall decoration, the warranty period is only about 5 years.

So, what is the difference between a fluorocarbon aluminum plate and a polyester aluminum veneer? There are traces of this. The simplest difference between the fluorocarbon aluminum plate and the polyester aluminum plate is the hardness of the surface paint, such as the nail on the surface of the polyester aluminum plate. If it is scratched hard, there will be slight scratches on the surface of the polyester aluminum plate, while the same fluorocarbon aluminum plate will not show any marks.

Since the fluorocarbon aluminum veneer is sprayed with fluorocarbon paint, it has excellent weather resistance. The spray thickness of the fluorocarbon aluminum veneer is generally about 30 μm (micron) for the second coat and about 40 μm (micron) for the third coat. , so it is used in buildings. The exterior wall decoration is very suitable.

At the same time, the use of fluorocarbon aluminum veneer can effectively isolate the contact between air and the plate, thereby preventing chemical reactions and making it last longer. In addition, fluorocarbon paint further stabilizes the chemical properties of the aluminum veneer due to its special molecular structure. Even after many years of use on the exterior wall, the fluorocarbon aluminum veneer can still keep bright as new, without discoloration or fading.