Today, we are going to explore the preferred high-temperature insulation material for environments ranging from 1400 to 1800℃ – CHAL Aluminum Industry’s Alumina Fibers. Depending on the alumina content and crystal phase, CHAL Aluminum Industry offers five product models: 72-F series, 72-M series, 85 series, 95-M series, and 95-N series.

Product Advantages

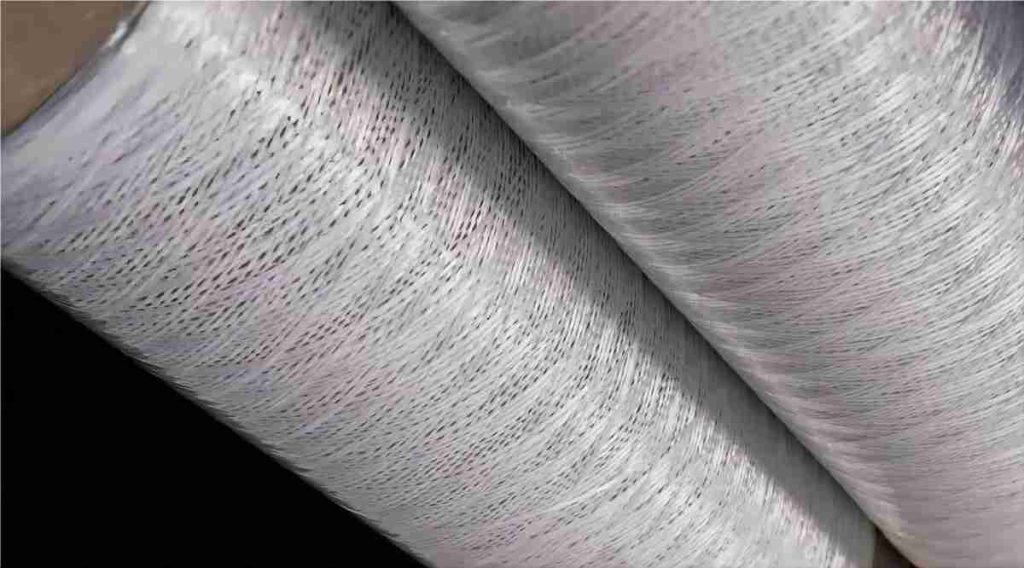

CHAL Aluminum Industry’s Alumina Fibers possess several significant advantages. With uniform diameters and a temperature resistance range of 1400 to 1800℃, these fibers combine the properties of crystal and fiber materials, resulting in incomparable features such as excellent thermal stability, high mechanical strength, large elastic modulus, low thermal conductivity, strong insulation, and resistance to chemical corrosion.

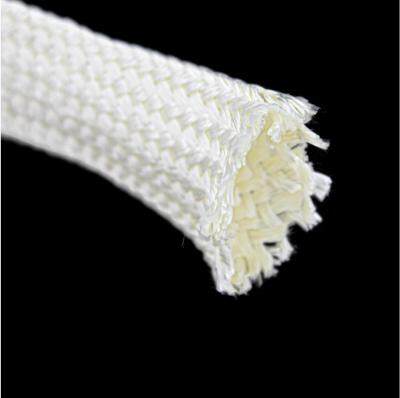

The basic form of the product is alumina fiber cotton, which finds applications in various industrial kilns as filling, sealing, and insulation materials, high-temperature filtration materials, and more. These fibers can also be processed into refractory products, aluminum alloy reinforcements, fiber-reinforced composites, and other products.

Advantage 1: Low Slag Ball Content, High Fiber Strength, Superior Refractory Performance

Compared to alumina fibers in the global market, CHAL‘s fibers have extremely low slag ball content and uniform diameters, resulting in a significant increase in fiber strength. As fiber insulation and refractory properties are inversely proportional to slag ball content, CHAL’s products offer higher insulation and refractory performance.

Currently, the finished fiber slag ball content (≤212μm) is ≤0.2%, the fiber diameter can be consistently controlled at 5-7μm, and the single filament strength is ≥1200MPa, all of which meet international standards.

Advantage 2: Good Flexibility, Strong Plasticity

CHAL‘s alumina fibers exhibit high flexibility and are not prone to breakage during further processing, making them the preferred material for downstream products in the fiber blanket, fiber paper, and fiberboard industries. For example, CHAL’s flagship product, the three-way catalyst pad, is made from these fibers. Additionally, the fibers can be directly used for sealing, filling, and insulation in the kiln industry and as reinforcements for metal-based, ceramic-based, and resin-based composite materials.

Technical Indicators of Alumina Fiber Products

| Technical index / product model number |

Type 72-F series | Model 72-M series | Type 85 | Type 95-M | Type 95 — N | |

| Chemical composition Al2: O3: SiO2 (%) |

72-75:25-28 | 72-75:25-28 | 85-88:12-15 | >95:<5 | >95:<5 | |

| Mineral structure | δ or δ + Mullite | Mullite | Mullite+α | γ | α | |

| Classification temperature (℃) | 1100 | 1600 | 1700 | 900 | 1800 | |

| melting point (℃) | >1800 | >1800 | >1900 | >2000 | >2000 | |

| Density(g/cm³) | 3.1 | 3.1 | 3.2 | 3.4 | 3.4 | |

| Average fiber diameter(μm) | 5-7 (Can be adjusted according to customer requirements) |

5-7 (Can be adjusted according to customer requirements) |

4-7 (Can be adjusted according to customer requirements) |

3-6 (Can be adjusted according to customer requirements) |

3-6 (Can be adjusted according to customer requirements) |

|

| Average fiber length (mm) | 50-100 | 30-100 | 20-100 | 10-100 | 10-100 | |

| Shot content(%) | ≥212μm | 0-0.2 | 0-0.5 | 0-0.2 | 0-0.2 | 0-0.2 |

| ≥75μm | 0-2 | 0-2 | 0-2 | 0.2 | 0-2 | |

| Impurity component(%) | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 | |

| intensity(MPa) | ≥1200 | ≥1000 | – | – | – | |

| modulus(GPa) | ≥100 | ≥100 | – | – | – | |

| 1 hour shrinkage(%) | under 1200℃≤4 | under 1500℃≤4 | under 1600℃≤2 | under 1200℃≤2 | under 1500℃≤2 | |

Main downstream products: fiber liners, fiber blankets, fiber papers, fiberboards, etc.

Industry Applications

72-F Series: Alumina fibers in this series demonstrate excellent flexibility and are used in the manufacturing of three-way catalyst pads for the automotive industry. They are also employed as reinforcements for metal-based, ceramic-based, and resin-based composite materials, as well as various types of blankets and felts in high-temperature fields.

72-M Series: These alumina fibers possess excellent high-temperature and chemical stability, making them suitable for the production of high-temperature fiberboards, shaped pieces, blankets, felts, and papers. They are the preferred material in high-temperature insulation fields for industries like steel, petrochemical, and ceramics kilns, being commonly used in the construction of kiln walls, roofs, kiln furniture, and muffle.

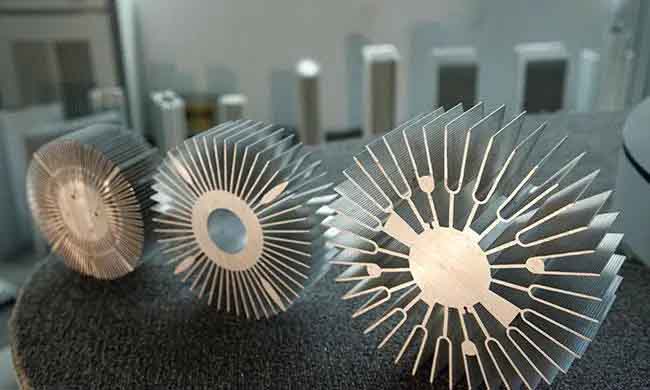

95-M Series: Alumina fibers in this series are widely applied in catalytic combustion and environmental waste gas treatment as high-temperature filter materials and catalyst carriers.

95-N Series: With even higher operating temperatures compared to the 72-II series alumina fibers, 95-N fibers are processed into fiberboards, shaped pieces, and other forms used in high-temperature insulation fields like aerospace.

Conclusion

CHAL Aluminum Industry’s Alumina Fibers are indispensable in high-temperature environments ranging from 1400 to 1800℃. With superior insulation, refractory performance, and versatility, they find applications in various industries, from automotive to aerospace. As technology continues to advance, these advanced materials will play an increasingly vital role in meeting the challenges posed by extreme temperatures in the modern world.