Aluminium square bars are versatile building materials used in a wide range of applications, from construction and engineering to furniture and decoration. They come in two main varieties: hollow and solid. Each type offers distinct advantages and applications. This article will guide you through the key differences between hollow and solid aluminium square bars to help you select the best option for your project.

What are Aluminium Square Bars?

Aluminum square bars are bars with a square cross-sectional shape made from aluminum. They are commonly used in various industries for applications where strength, durability, and corrosion resistance are required.

These bars are manufactured through the process of extrusion, where aluminum billets are forced through a die to create the desired shape. The square shape provides additional strength compared to other profiles like round bars and can be easily machined, welded, and formed to fit specific requirements.

Aluminum square bars find applications in industries such as construction, automotive, aerospace, marine, and manufacturing. They are used in structural frameworks, support beams, architectural trim, machine parts, and various other components where lightweight yet sturdy material is needed.

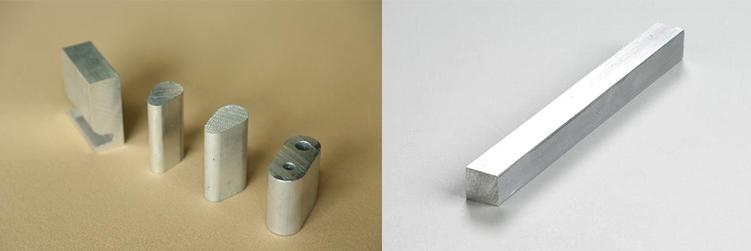

Aluminium square bars can be divided into hollow and solid types based on their cross-sectional geometry. Here’s how they differ:

- Solid Aluminium Square Bars: These bars have a uniform, solid cross-section throughout their length. They are made entirely of solid aluminium material without any voids or hollow spaces in the center.

- Hollow Aluminium Square Bars: These bars have a hollow cross-section, with a void or empty space in the center. The walls of the bar form a square or rectangular shape, enclosing the empty space within.

The distinction between hollow and solid aluminium square bars is based solely on the presence or absence of a void or hollow space within the cross-sectional area of the bar. Let’s know more details of this two types.

Hollow Aluminium Square Bars

Hollow aluminium square bars are a type of aluminium extrusion characterized by their square cross-sectional shape and empty interior. These bars offer several advantages:

- Weight Reduction: Hollow aluminium square bars are significantly lighter than their solid counterparts due to the absence of material in the interior. This weight reduction makes them ideal for applications where minimizing mass is critical, such as aerospace and automotive components, where lighter structures can improve fuel efficiency and performance.

- Enhanced Strength-to-Weight Ratio: Despite their lighter weight, hollow aluminium square bars maintain a high strength-to-weight ratio. This characteristic ensures structural integrity while reducing the overall load on supporting structures.

- Improved Thermal Conductivity: The hollow design of these bars allows for better thermal conductivity compared to solid bars. This property is beneficial in applications requiring efficient heat transfer, such as heat exchangers and cooling systems in industrial equipment and electronics.

- Cost Savings: Hollow aluminium square bars can offer cost savings compared to solid bars, as they require less raw material for production. Additionally, their lighter weight may result in reduced transportation and handling costs.

- Design Flexibility: Manufacturers can customize the dimensions, wall thickness, and internal profiles of hollow aluminium square bars to meet specific project requirements. This design flexibility allows for tailored solutions in a wide range of applications.

Overall, hollow aluminium square bars offer a combination of lightweight design, strength, thermal conductivity, and corrosion resistance, making them versatile solutions for a wide range of industrial applications where performance and efficiency are paramount.

Solid Aluminium Square Bars

Solid aluminium square bars, unlike their hollow counterparts, do not have an empty interior but instead consist of solid aluminium throughout their cross-sectional area. These bars offer several advantages due to their unique properties:

- High Strength and Rigidity: Solid aluminium square bars are known for their exceptional strength and rigidity. The absence of voids or hollow spaces contributes to their structural integrity, making them suitable for load-bearing applications where durability is paramount.

- Ease of Machining: Solid aluminium square bars are easier to machine compared to hollow bars. Their uniform composition allows for precise cutting, drilling, and shaping, making them ideal for manufacturing custom components and parts with intricate designs.

- Versatility: Solid aluminium square bars are available in various sizes, thicknesses, and alloys, offering versatility in a wide range of applications. They can be easily fabricated, welded, and joined to meet specific project requirements across different industries.

- Corrosion Resistance: Like all aluminium alloys, solid aluminium square bars exhibit excellent corrosion resistance, even in harsh environments. This property ensures longevity and durability in outdoor applications and corrosive conditions, making them suitable for marine, architectural, and industrial use.

- Cost-Effectiveness: Solid aluminium square bars may offer cost advantages in certain applications due to their simpler manufacturing process and lower material wastage compared to hollow bars. They provide a cost-effective solution for projects where high strength and durability are required.

- Consistent Mechanical Properties: Solid aluminium square bars exhibit consistent mechanical properties throughout their entire cross-section, ensuring predictable performance in structural applications. This uniformity makes them reliable for critical components and load-bearing structures.

Overall, solid aluminium square bars offer a combination of strength, rigidity, ease of machining, corrosion resistance, and cost-effectiveness, making them versatile materials for a wide range of industrial applications. Whether used in construction, manufacturing, automotive, or architectural projects, solid aluminium square bars provide reliable performance and durability in demanding environments.

Comparison of Hollow and Solid Aluminium Square Bars

Here’s a comparison of hollow and solid aluminum square bars:

- Weight: The most noticeable difference between hollow and solid aluminum square bars is their weight. Solid bars are denser and therefore heavier compared to hollow bars of the same dimensions. This makes hollow bars advantageous in applications where weight reduction is critical, such as aerospace or automotive industries.

- Strength: Solid aluminum bars generally have higher strength and stiffness compared to hollow bars of the same material and dimensions. This is because the material is distributed uniformly throughout the solid bar, providing more resistance to bending and torsional forces. However, hollow bars can be engineered with thicker walls to achieve similar strength characteristics while still reducing weight.

- Cost: Hollow aluminum bars typically require less material to manufacture compared to solid bars of the same dimensions. As a result, hollow bars are often more cost-effective, especially in applications where weight reduction is a significant factor. However, the manufacturing process for hollow bars may be more complex, which can affect production costs.

- Corrosion Resistance: Both hollow and solid aluminum bars offer excellent corrosion resistance, thanks to the natural oxide layer that forms on the surface of aluminum when exposed to air. This oxide layer acts as a protective barrier against corrosion, making aluminum suitable for a wide range of indoor and outdoor applications, including marine environments.

- Versatility: Solid aluminum bars are generally more versatile and can be used in a wider range of applications compared to hollow bars. Solid bars are often preferred in structural applications where high strength and rigidity are required, such as in construction or machinery. However, hollow bars are also versatile and can be used in applications where weight reduction and corrosion resistance are priorities.

- Machinability: Both hollow and solid aluminum bars are relatively easy to machine using standard metalworking tools and techniques. However, solid bars may be slightly easier to machine due to their uniform composition. Hollow bars may require special considerations during machining to ensure that the walls remain structurally sound.

This table summarizes the key differences between hollow and solid aluminum square bars across various aspects such as weight, strength, cost, corrosion resistance, versatility, and machinability.

| Aspect | Hollow Aluminum Square Bars | Solid Aluminum Square Bars |

| Weight | Lighter due to less material | Heavier due to denser material |

| Strength | Generally lower strength compared to solid bars | Higher strength and stiffness |

| Cost | Often more cost-effective | May be more expensive due to more material |

| Corrosion Resistance | Excellent corrosion resistance | Excellent corrosion resistance |

| Versatility | Versatile, suitable for weight-sensitive applications | Widely used in various applications due to high strength |

| Machinability | Relatively easy to machine | Relatively easy to machine |

In summary, the choice between hollow and solid aluminum square bars depends on the specific requirements of the application, including factors such as weight, strength, cost, corrosion resistance, and machining considerations. Hollow bars offer advantages in weight reduction and cost-effectiveness, while solid bars provide higher strength and stiffness.

Factors to Consider When Choosing Between Hollow and Solid Aluminium Square Bars

When choosing between hollow and solid aluminum square bars, several factors should be considered to ensure the most suitable option for your specific application. Here are some key factors to consider:

- Weight Requirements: Determine whether weight reduction is critical for your application. Hollow aluminum bars are lighter than solid bars due to their reduced material volume, making them preferable for weight-sensitive applications such as aerospace or automotive industries.

- Strength and Stiffness: Assess the structural requirements of your project. Solid aluminum bars generally offer higher strength and stiffness compared to hollow bars of the same material and dimensions. Consider whether the strength and rigidity provided by solid bars are necessary for your application.

- Cost Considerations: Evaluate the cost-effectiveness of both options. Hollow aluminum bars typically require less material to manufacture compared to solid bars of the same dimensions, making them potentially more cost-effective. However, consider other factors such as manufacturing complexity and machining costs.

- Corrosion Resistance: Ensure that the chosen aluminum bars offer adequate corrosion resistance for the intended environment. Both hollow and solid aluminum bars naturally form an oxide layer that protects against corrosion. Consider the specific conditions in which the bars will be used, such as exposure to moisture or chemicals.

- Application Versatility: Consider the versatility of each option for different applications. Solid aluminum bars are generally more versatile and can be used in a wider range of structural and load-bearing applications. However, hollow bars are also versatile and offer advantages in weight-sensitive applications where corrosion resistance is crucial.

- Machinability: Evaluate the ease of machining for both hollow and solid aluminum bars. While both options are relatively easy to machine using standard metalworking tools and techniques, solid bars may be slightly easier to machine due to their uniform composition. Consider any special machining considerations required for hollow bars, such as maintaining structural integrity while machining.

- Aesthetic Requirements: Consider any aesthetic preferences or design considerations for your project. Hollow aluminum bars may offer a different visual appearance compared to solid bars, which can affect the overall design aesthetic of your project.

By carefully considering these factors, you can make an informed decision when choosing between hollow and solid aluminum square bars for your specific application.

Conclusion

By understanding the advantages and applications of hollow and solid aluminium square bars, you can make an informed decision for your project. If you prioritize weight reduction and material efficiency, hollow bars may be suitable. However, if superior strength, rigidity, and load-bearing capacity are essential, solid bars are the better choice. When unsure, consult with a professional to determine the best aluminium square bar type for your specific needs. CHAL is one of the best choices for you.