For centuries, the construction industry has relied heavily on traditional materials like steel and concrete. While these materials have proven their worth in countless projects, they also present certain limitations. Steel, for instance, is susceptible to corrosion and can be incredibly heavy, making transportation and construction challenging. Concrete, while strong in compression, is relatively weak in tension and prone to cracking. These limitations have driven a search for alternative materials that offer superior performance and efficiency. In recent years, aluminum has emerged as a compelling contender, transforming how engineers approach construction projects, and offering new possibilities for strength, sustainability, and efficiency.

Unique Properties of Aluminum Beams

Aluminum possesses a unique combination of physical and chemical properties that make it an ideal material for structural applications. Its inherent characteristics provide a significant advantage over traditional materials like steel and concrete, offering enhanced performance and sustainability.

Physical and Chemical Properties:

- Lightweight: Aluminum boasts an exceptionally low density, making it significantly lighter than steel for a given volume. This low weight translates to reduced transportation costs, easier handling during construction, and overall project efficiency.

- High Strength-to-Weight Ratio: Despite its low density, aluminum exhibits remarkable strength. It possesses a high strength-to-weight ratio, meaning it can support significant loads while minimizing the amount of material used. This is crucial for achieving slender, lightweight structures that are both aesthetically pleasing and structurally sound.

- Excellent Corrosion Resistance: Aluminum naturally forms a thin, protective oxide layer on its surface, providing excellent resistance to corrosion. This inherent protection significantly enhances the material’s durability and longevity, reducing the need for extensive maintenance and costly repairs.

- High Ductility and Formability: Aluminum is highly ductile, meaning it can be easily shaped and formed into various complex geometries. This versatility allows for innovative and intricate designs that would be difficult or impossible to achieve with other materials.

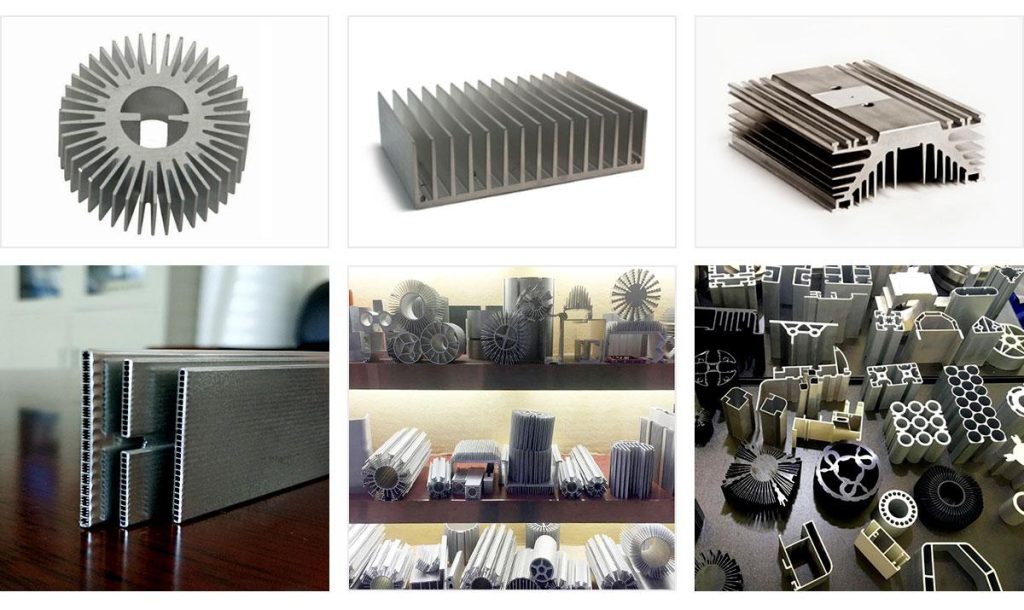

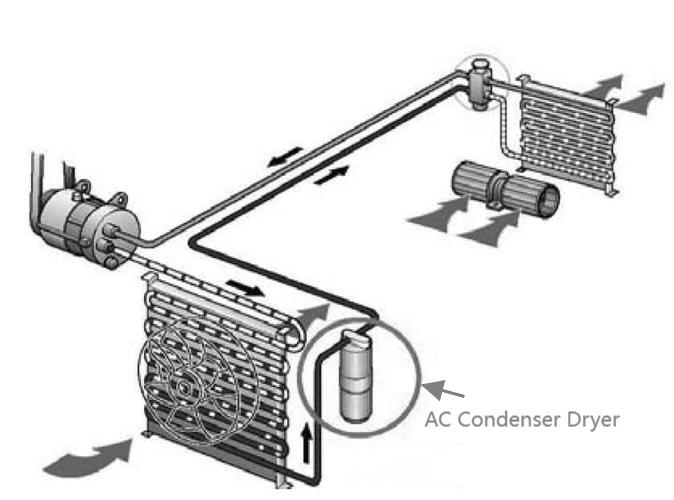

- Good Thermal and Electrical Conductivity: While not always a primary concern in structural applications, aluminum’s high thermal and electrical conductivity can be advantageous in certain situations, such as in applications involving heat dissipation or electrical grounding.

Advantages Over Traditional Materials:

- Aluminum vs Steel: Compared to steel beams, aluminum beams are significantly lighter. In large-scale construction projects such as buildings and bridges, reducing self-weight can lessen the load on the foundation, thereby lowering construction costs. For example, when building high-rise structures on soft soil, using aluminum beams as part of the structural materials can reduce the overall weight of the building and lower the risk of foundation settlement.

- Aluminum vs Wood: Compared to wood, aluminum beams offer superior fire resistance. In areas with high fire risks or buildings with stringent fire safety requirements (such as shopping malls and hospitals), aluminum beams can provide more reliable structural safety. Moreover, unlike wood, aluminum beams are not susceptible to insect damage or rot, and thus have a longer service life.

- Aluminum vs Concrete: Compared with concrete, aluminum beams have a higher strength-to-weight ratio. Although concrete has a high compressive strength, it is heavy and does not have an advantage in some projects that have strict restrictions on the deadweight of the structure. In addition, the construction speed of aluminum beams is relatively fast. Concrete needs a certain curing time after pouring to reach the design strength, while aluminum beams can bear a certain load after installation, which can effectively shorten the construction period. Moreover, aluminum beams are easier to handle than concrete during later renovation or demolition, and their materials can be recycled and reused, while most concrete can only be treated as construction waste after demolition.

The advantages of aluminum beams over traditional materials (steel, wood, concrete) solve the pain points of traditional materials in many aspects, provide a more optimized choice for structural engineering, and can meet the strict requirements of modern engineering for materials in many aspects.

Applications of Aluminum Beams in Structural Engineering

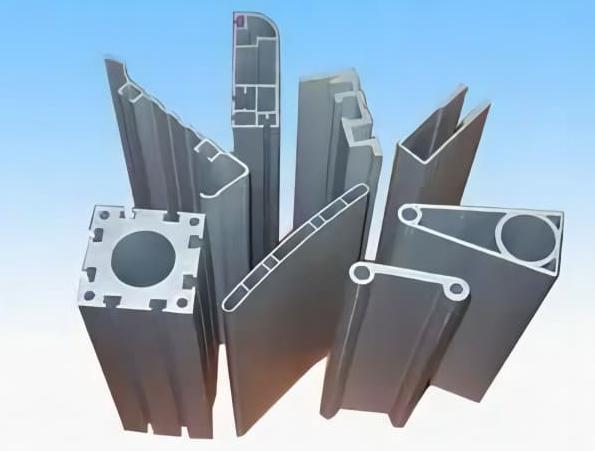

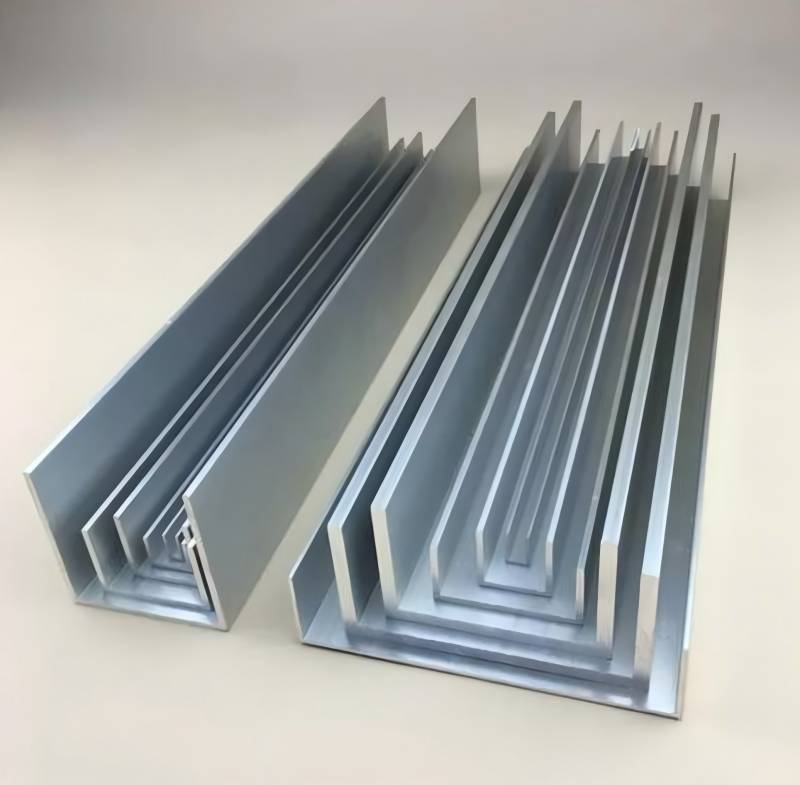

Aluminum beams have found widespread application in various sectors of structural engineering, revolutionizing the construction from high-rise buildings and bridges to renewable energy structures. It can be manufactured through processes such as extrusion or rolling, and have various cross-sectional shapes to meet different structural requirements. Common aluminum beams including I-beams, H-beams, T-beams, and C-beams.

Common Types of Aluminum Beams and Their Applications

- Aluminum I-Beams: Commonly used in construction for frameworks and support structures, I-beams provide excellent load-bearing capacity while maintaining a lightweight profile.

- Aluminum H-Beams: Similar to I-beams but with wider flanges, H-beams are ideal for heavy-duty applications where enhanced stability is needed.

- Aluminum T-Beams: Frequently used in bridges and architectural designs, T-beams offer versatility in combining structural integrity with aesthetic appeal.

- Aluminum C-Beams: Recognized for their C-shaped cross-section, these beams are often used in framing and bracing applications. Their design offers high strength while allowing easy integration with other structural components.

These beams are utilized in diverse fields, including residential and commercial buildings, transportation infrastructure, and industrial machinery.

Challenges and Solutions

Despite their many advantages, aluminum beams are not without challenges. Their relatively high initial cost compared to steel can be a deterrent. However, this is often offset by lower lifecycle costs due to durability and reduced maintenance needs.

Another challenge is the lower modulus of elasticity in aluminum compared to steel, which means it can deform more under heavy loads. Engineers address this by designing thicker or specially reinforced beams to handle specific stresses. Advances in alloying and fabrication techniques continue to expand aluminum’s capabilities, making it increasingly competitive with traditional materials.

The Impact of Aluminum Beams on Structural Engineering Design Concepts

Traditional structural engineering design concepts are largely limited by material properties. For example, when designing large buildings or bridges, it is necessary to focus on the impact of the material’s own weight on the structure. The lightweight and high-strength characteristics of aluminum beams break this limitation, allowing designers to be bold in innovative design and no longer be limited to traditional structural forms. For example, more complex and lightweight architectural shapes can be designed, such as some modern buildings with unique curves and cantilever structures.

The sustainability characteristics (recyclability) of aluminum beams also prompt the design concept to shift towards green and environmental protection. When designers conduct structural engineering design, they will consider the entire life cycle of the material more, from mining, processing, and use to recycling. Choosing aluminum beams helps achieve the sustainable development goals of structural engineering.

Aluminum beams have prompted a shift in the concept of structural engineering design, from traditional design based on material limitations to a more free, innovative, and sustainable direction.

Aluminum beams have shown great potential in structural engineering due to their unique properties. Their physical and chemical properties, advantages over traditional materials, and applications in different projects are redefining structural engineering. Although there are still some challenges, with the advancement of technology and the improvement of specifications, the position of aluminum beams in structural engineering will become increasingly important. It will continue to promote the development of structural engineering in a more efficient, environmentally friendly and innovative direction, bringing more possibilities for future buildings and infrastructure construction.