In the modern world, where electronic devices and communication systems are integral to daily life, the importance of protecting cables cannot be overstated. Cables are the lifelines of electrical and electronic systems, enabling the transfer of power and data. However, they are susceptible to various forms of interference and damage. One effective method to safeguard these vital components is by using aluminum foil. This article delves into how aluminum foil is used to protect cables, examining its properties and the specific role it plays in ensuring the integrity and functionality of cabling systems.

Understanding Cable Protection

Cables, whether used in household electronics, industrial machinery, or communication networks, are prone to physical damage and electromagnetic interference (EMI). Physical damage can result from abrasion, moisture, and mechanical stress, while EMI can disrupt the signals transmitted through cables, leading to data loss or corruption. Effective cable protection is essential to maintain the performance and longevity of these systems. Protective measures include physical shielding, insulating materials, and the use of conductive barriers to prevent interference.

Why Choose Aluminum Foil for Cable Protection?

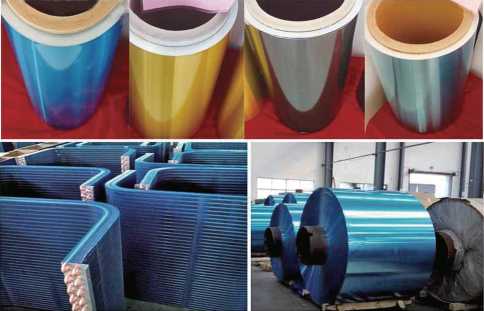

When it comes to ensuring the integrity and performance of cables in various applications, selecting the right protective material is crucial. Aluminum foil stands out as a preferred choice for cable protection due to its unique combination of properties and benefits. Here are several compelling reasons why aluminum foil is the material of choice for safeguarding cables:

1. Excellent Electromagnetic Shielding

One of the primary reasons for using aluminum foil in cable protection is its exceptional ability to shield against electromagnetic interference (EMI). EMI can disrupt the signals transmitted through cables, leading to data loss and degradation in performance. Aluminum foil acts as a conductive barrier that effectively reflects and absorbs electromagnetic waves, preventing them from penetrating the cable. This ensures the integrity and reliability of the signals, making aluminum foil indispensable in environments with high levels of electromagnetic activity, such as industrial facilities, data centers, and urban areas with dense electronic infrastructure.

2. Lightweight and Flexible

Aluminum foil is both lightweight and highly flexible, which makes it easy to apply around cables of various shapes and sizes without adding significant weight or bulk. This flexibility allows the foil to form a tight, conforming layer around the cable, ensuring comprehensive coverage and protection. The ease of application also makes aluminum foil a practical choice for manufacturers and installers, facilitating efficient and effective cable protection.

3. Corrosion Resistance

Cables are often exposed to harsh environmental conditions, including moisture, chemicals, and fluctuating temperatures. Aluminum foil is resistant to corrosion, providing a durable protective barrier that extends the lifespan of the cables. This corrosion resistance is particularly important in outdoor applications and in environments where cables are subjected to moisture or chemical exposure.

4. Cost-Effective

Compared to other shielding materials, aluminum foil is relatively inexpensive. Its cost-effectiveness, combined with its high performance, makes it an attractive option for cable manufacturers and consumers alike. By using aluminum foil, manufacturers can provide high-quality cable protection without significantly increasing production costs, which in turn makes the end product more affordable for consumers.

5. Heat Dissipation

Aluminum has excellent thermal conductivity, which means it can effectively dissipate heat generated within the cable. This property helps to maintain optimal operating temperatures, preventing overheating and potential damage to the cable and its components. By managing heat efficiently, aluminum foil contributes to the overall reliability and safety of the cable system.

6. Physical Protection

In addition to its electromagnetic shielding capabilities, aluminum foil also offers robust physical protection. It acts as a barrier against abrasion, punctures, and other mechanical stresses that can damage the cable. Moreover, it protects against moisture ingress, which can lead to short circuits and other electrical failures. The physical durability of aluminum foil ensures that cables remain intact and functional even in demanding environments.

7. Versatility in Applications

Aluminum foil is used in a wide range of cable types, including coaxial cables, Ethernet cables, and audio/video cables. Its versatility makes it suitable for various applications, from consumer electronics and home networking to industrial automation and telecommunications. This adaptability underscores the value of aluminum foil as a universal solution for cable protection across different industries and use cases.

Choosing aluminum foil for cable protection offers numerous advantages, from its superior electromagnetic shielding and physical durability to its cost-effectiveness and ease of application. Its unique combination of properties makes it an ideal material for safeguarding cables against a variety of threats, ensuring reliable performance and longevity.

Application in Different Types of Cables

The applications of aluminum foil in cable protection are diverse and extensive, spanning various industries and use cases. Here are some key applications of aluminum foil in cable protection:

| Application | Brief Introduction |

| Coaxial Cables | Used for television and internet connections, aluminum foil shields against EMI to ensure clear signals. |

| Ethernet Cables | Shields against electromagnetic and radio frequency interference, enhancing data transmission speed. |

| Audio and Video Cables | Preserves signal quality by preventing noise and interference, ensuring clear audio and video signals. |

| Shielded Twisted Pair (STP) Cables | Provides individual shielding for twisted pairs to reduce crosstalk and external interference. |

| Power Cables | Protects against electromagnetic interference and enhances cable durability for efficient energy distribution. |

| Automotive Wiring | Shields wiring harnesses from EMI and physical damage, ensuring reliable vehicle electronic systems. |

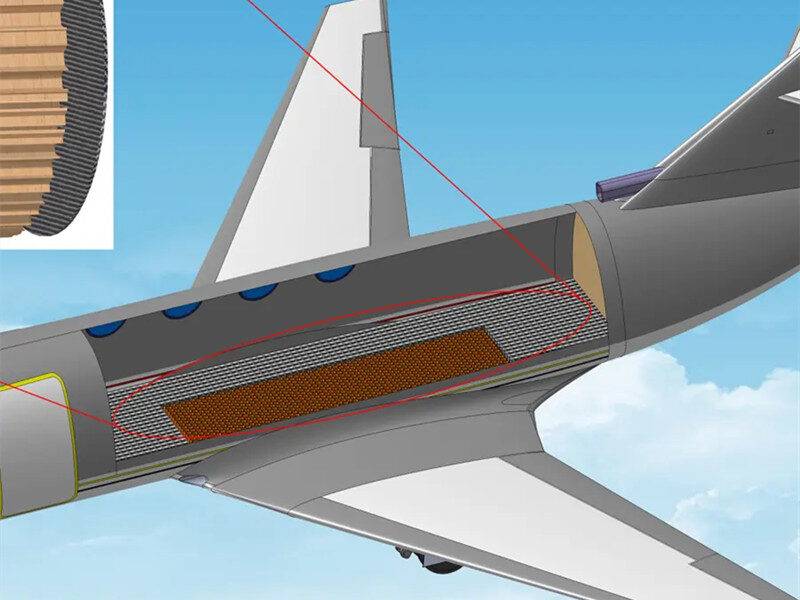

| Aerospace and Defense | Protects cables in harsh conditions, ensuring performance of critical systems in aerospace and defense. |

| Medical Equipment | Ensures accurate data transmission and reduces interference in medical devices and equipment. |

| Industrial Automation | Protects cables from EMI and physical damage, ensuring reliable operation of automated industrial processes. |

The protection of cables is essential for the efficient functioning of electrical and electronic systems. Aluminum foil, with its excellent conductive properties and physical durability, plays a vital role in shielding cables from electromagnetic interference and physical damage. By employing aluminum foil in cable design, manufacturers can ensure the reliability and longevity of their products, ultimately contributing to the seamless operation of modern technological infrastructures. It’s important to note that for professional installations, pre-manufactured shielded cables are recommended, as they offer a more robust and reliable shielding solution.