As the global demand for sustainable energy continues to grow, electric vehicles (EVs) are rapidly becoming mainstream in the automotive industry as a key technology to reduce carbon emissions and dependence on fossil fuels. Battery boxes, as a vital component of electric vehicles, not only carry battery cells, but also directly affect the vehicle’s range and safety. Aluminum materials, with their unique properties, have become one of the preferred materials for battery box manufacturing, providing important guarantees for the performance improvement and safety protection of electric vehicles.

Get to Know the Battery Cases in EVs

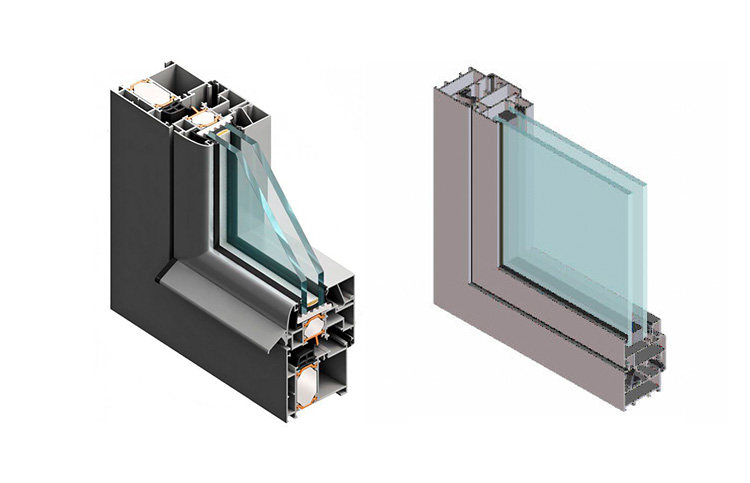

The importance of the battery box in electric vehicles is that it not only needs to provide a strong structure to protect the expensive and sensitive battery cells, but also must ensure thermal management of the battery, prevent overheating and protect the passengers and battery from accidental situations such as collisions. damage. The design and material selection of the battery box directly affects the performance and safety standards of electric vehicles.

Why Aluminum is Used in Electric Car Battery Cases:

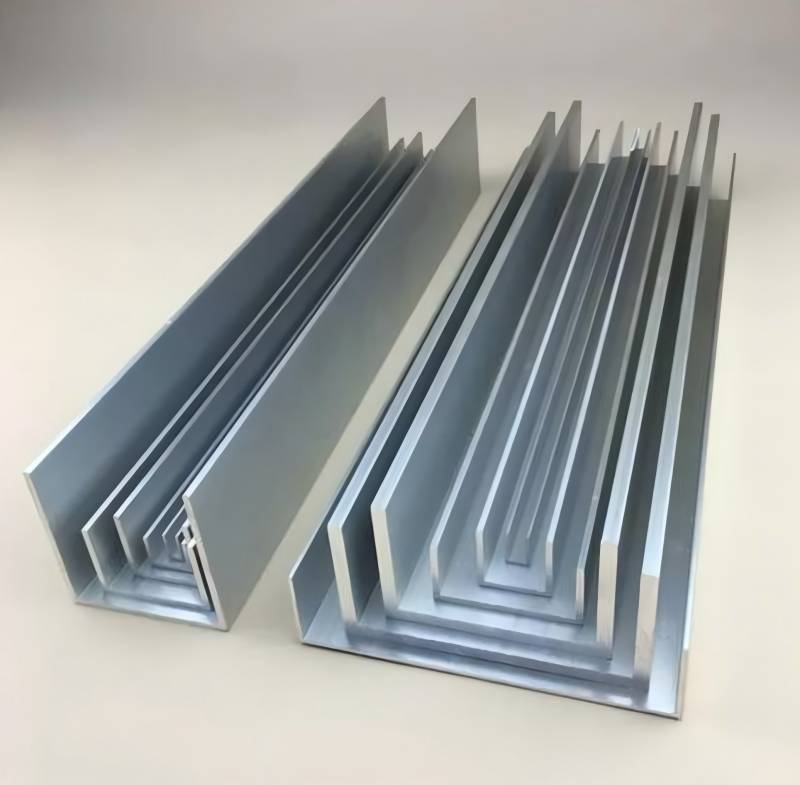

- Lightweight: Aluminum is a lightweight metal. The use of aluminum materials can significantly reduce the weight of the battery box, thereby reducing the overall weight of the electric vehicle, which is crucial to increasing the cruising range.

- Strength and corrosion resistance: Aluminum and its alloys have good mechanical strength and corrosion resistance, and can effectively protect battery cells from external impact and environmental factors.

- Thermal management: Aluminum has good thermal conductivity, which helps the thermal management of the battery box. Through efficient heat dissipation, it maintains the battery within a suitable operating temperature range and improves battery efficiency and lifespan.

How Aluminum Material in EV Battery Cases Influences Range and Safety

The aluminum material in electric vehicle battery boxes significantly affects the vehicle’s range and safety through its lightweight, strength, corrosion resistance and thermal management capabilities.

Influence of Aluminum on EV Range

One of the most significant advantages of using aluminum in EV battery cases is its contribution to enhancing the vehicle’s range. The lightweight nature of aluminum reduces the overall weight of the vehicle, which in turn lowers the energy required to propel it. This energy efficiency translates into an extended driving range, allowing the vehicle to travel further on a single charge.

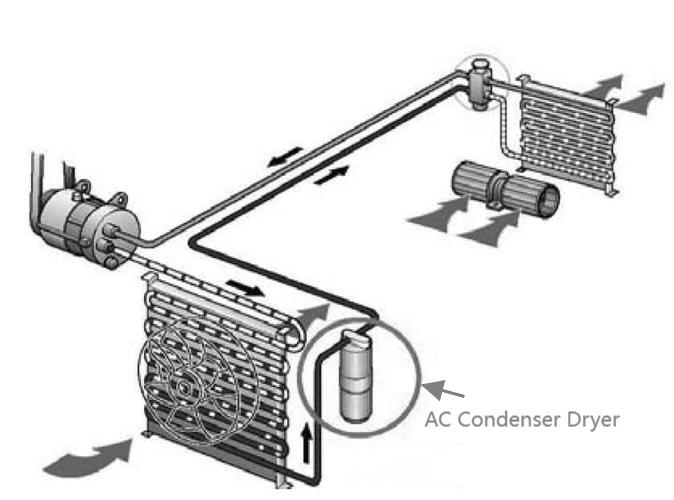

In addition to its lightweight properties, aluminum’s excellent thermal conductivity plays a crucial role in maintaining the battery’s temperature within optimal limits. Efficient thermal management prevents the battery from overheating, which can otherwise lead to reduced efficiency and shortened battery life. By helping to keep the battery cool, aluminum ensures that the battery operates at its peak efficiency, further enhancing the vehicle’s range.

Influence of Aluminum on EV Safety

Safety is a paramount concern in the design and manufacturing of EV battery cases, and aluminum excels in this regard as well. The strength-to-weight ratio of aluminum is impressive, meaning that it can provide substantial protection without adding excessive weight. In the event of a collision, aluminum battery cases are capable of absorbing and dissipating impact energy, reducing the risk of damage to the battery cells and minimizing the chances of a fire.

Furthermore, aluminum’s high thermal conductivity helps prevent thermal runaway, a dangerous chain reaction that can occur when a battery cell overheats. By efficiently dissipating heat, aluminum reduces the likelihood of such incidents, ensuring the safety of both the vehicle and its occupants. Additionally, aluminum’s natural corrosion resistance ensures that the battery case remains intact and effective even after prolonged exposure to various environmental conditions, further enhancing the overall safety of the EV.

Balancing Range and Safety with Aluminum

One of the key challenges in EV design is balancing the need for an extended range with the requirement for robust safety features. Aluminum, with its combination of lightweight and strong protective properties, allows for this balance to be achieved effectively. By reducing the vehicle’s weight, aluminum contributes to improved range without compromising safety. On the other hand, its strength and thermal management capabilities ensure that the battery is well-protected, even in extreme conditions.

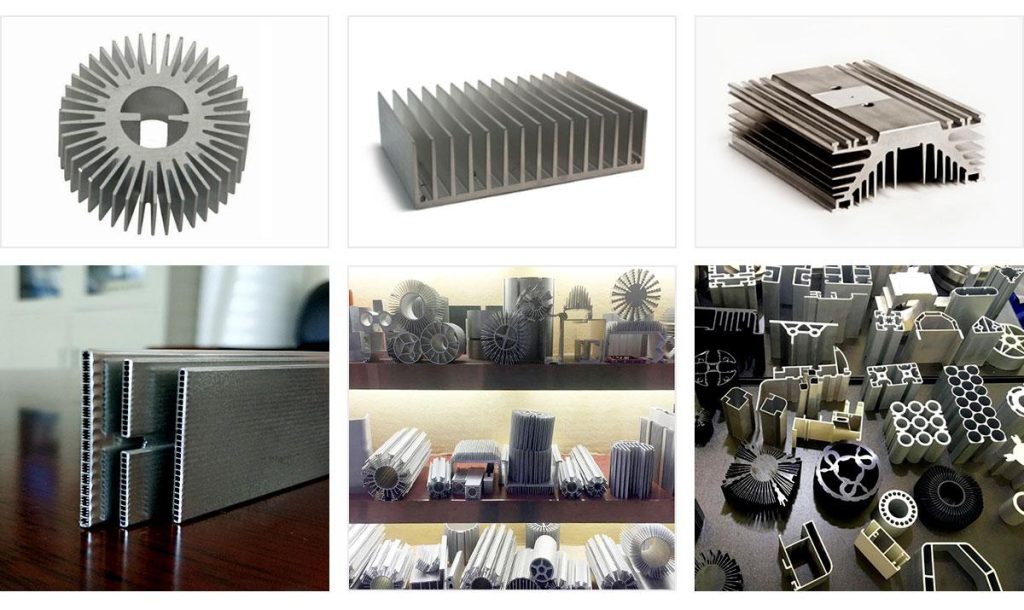

With the continuous development of electric vehicle technology, the application of aluminum materials in battery boxes will become more extensive. Manufacturers can optimize the use of aluminum by carefully designing battery cases that maximize its benefits. For instance, the use of advanced aluminum alloys can further enhance the material’s performance, offering even better protection and thermal management while maintaining or even reducing weight. This balance is crucial as it allows EVs to meet the high expectations of consumers in terms of both performance and safety, also making greater contributions to promoting green travel and sustainable development.