From enhancing the aesthetics of vehicle exteriors to improving functionality and durability, Aluminum paste plays a crucial role in various aspects of automobile manufacturing and design. This article explores the specific applications of aluminum paste in automobiles and the methods employed to apply it during manufacturing.

Specific Applications of Aluminum Paste in Automobile

Aluminum paste is commonly used in automobiles for various purposes, primarily in the manufacturing of paints and coatings applied to automotive bodies and components. Here’s how aluminum paste is used in automobiles:

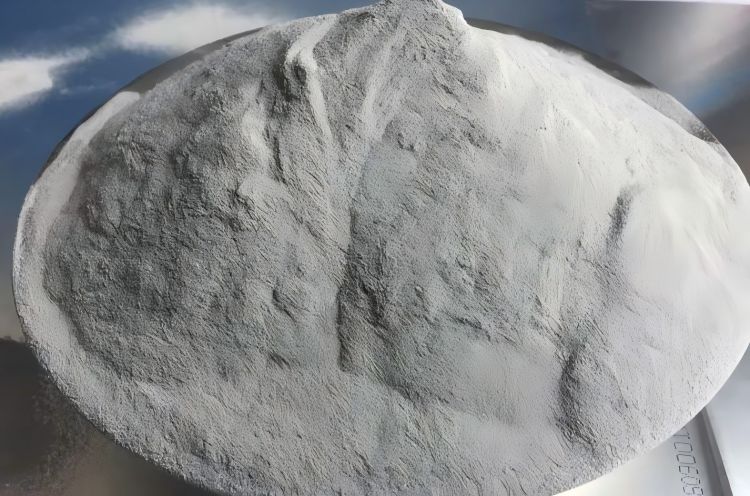

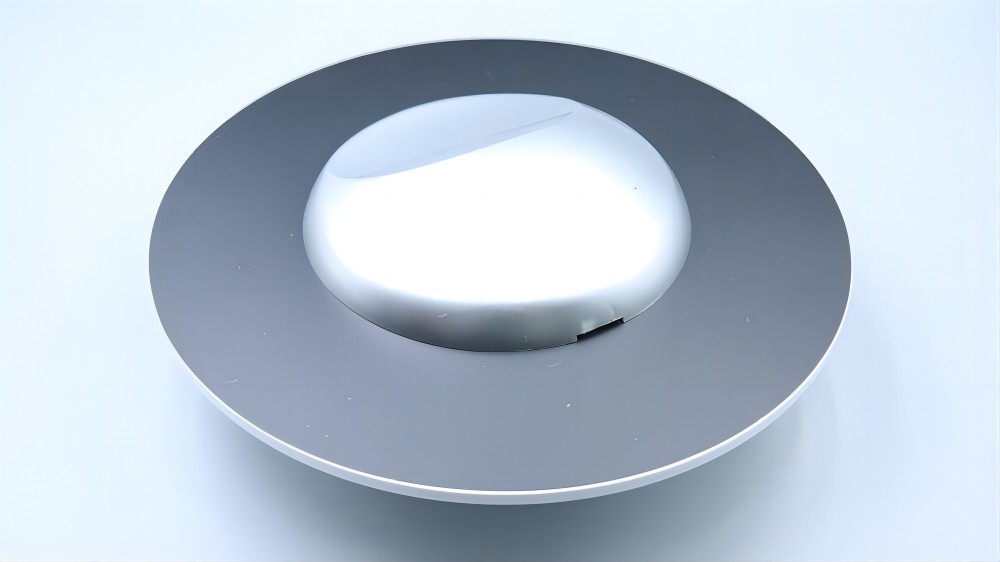

- Paint and Coatings: Aluminum paste is commonly used in automotive paints and coatings to impart metallic effects and enhance the visual appeal of vehicles. When mixed with automotive paint, aluminum paste creates a lustrous finish that adds depth and brilliance to the exterior surface. This metallic luster not only improves the overall aesthetics but also helps to reflect sunlight, reducing heat buildup and improving energy efficiency.

- Conductive Adhesives: In electric and hybrid vehicles, aluminum paste is utilized in conductive adhesives for bonding electronic components and ensuring reliable electrical connections. These adhesives contain aluminum particles dispersed in a conductive resin matrix, providing both mechanical strength and electrical conductivity. This application is critical for maintaining the performance and efficiency of electrical systems in modern automobiles.

- Thermal Management: Aluminum paste is incorporated into thermal interface materials (TIMs) used for heat dissipation in automotive electronics and powertrain components. By facilitating efficient heat transfer between heat-generating components and heat sinks, aluminum paste helps prevent overheating and ensures the optimal functioning of critical vehicle systems. This is particularly important in high-performance vehicles and electric vehicles where thermal management is paramount.

- Sound Insulation: Aluminum paste is sometimes integrated into automotive sound deadening materials to reduce noise and vibration inside the vehicle cabin. By adding aluminum particles to soundproofing materials, manufacturers can enhance their acoustic absorption properties, resulting in a quieter and more comfortable driving experience for passengers.

Overall, aluminum paste plays a crucial role in enhancing the aesthetic appeal, durability, and performance of automotive coatings, contributing to the overall quality and longevity of automobiles.

What Methods are Employed to Apply Aluminum Paste in Automotive Manufacturing?

The application of aluminum paste in automotive manufacturing involves several methods, each tailored to specific requirements and desired outcomes:

- Spray Painting: Aluminum paste can be applied to automotive parts using spray painting techniques. This method involves atomizing the paste into fine particles and spraying it onto the surface of the parts using compressed air or specialized spray equipment.

- Brushing or Roll-Coating: In some cases, aluminum paste may be applied to automotive components using brushes or rollers. This method allows for precise application and control over the thickness of the coating.

- Screen Printing: Screen printing is another method used to apply aluminum paste onto automotive parts. This technique involves forcing the paste through a fine mesh screen onto the surface of the parts, creating a uniform and controlled layer of the paste.

- Electrostatic Coating: Electrostatic coating involves charging the aluminum paste particles and then applying them to the automotive parts using an electrostatic field. This method ensures even coverage and can be more efficient than conventional spray painting methods.

- Dip Coating: Dip coating involves immersing the automotive parts into a tank containing the aluminum paste solution. The parts are then withdrawn from the tank, and excess paste is drained off, leaving a uniform coating on the surface.

- Powder Coating: Although less common for aluminum paste, powder coating can also be used in automotive manufacturing. This method involves electrostatically charging dry powder particles and then applying them to the surface of the automotive parts. The parts are then heated to melt and fuse the powder, forming a durable coating.

Conclusion

In conclusion, aluminum paste is a versatile material that finds wide-ranging applications in automobile manufacturing. From enhancing the visual appeal of vehicle exteriors to improving thermal management and sound insulation, aluminum paste contributes to the performance, durability, and aesthetics of modern automobiles. By employing various application methods such as spray painting, screen printing, roller coating, and dispensing, automotive manufacturers can leverage the unique properties of aluminum paste to meet the diverse requirements of today’s automotive industry.