For customers who don’t know much about aluminum tubes, they often ask such questions: Why do aluminum tubes that look the same are so different in their hardness? Is aluminum hardness directly related to its quality? In fact, there is already a difference in hardness of aluminum tubes during production. There are several factors that can affect the hardness of aluminum tubes during production, and this article will focus on the impact of the production environment temperature on the hardness of aluminum tubes.

As a manufacturer of professional Aluminum Tube for more than ten years, CHAL will help you to answer this question.

Manufacture at different Temps Comes Out with Different Hardness

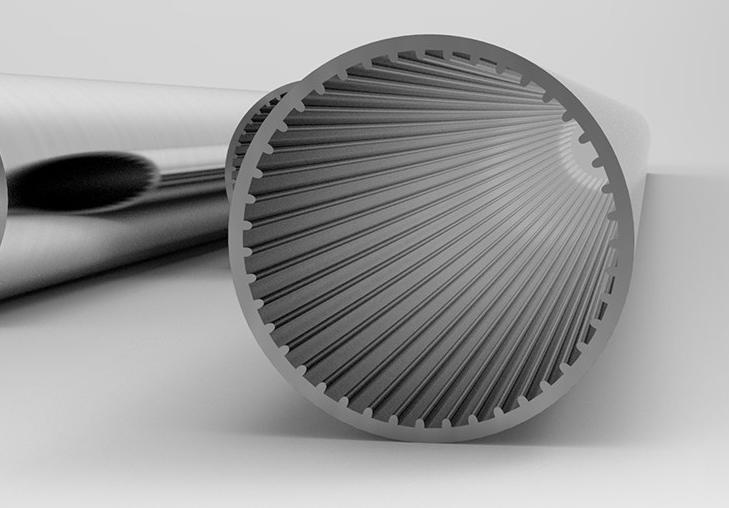

After extrusion, the aluminum tube will pass through the cold bed, and then be straightened into the aging furnace for artificial aging treatment, the purpose is to meet the aluminum tube aging treatment, get a better hardness.

Aluminum profiles are divided into AL6063 and AL6061 aluminum alloy according to the material, the hardness after aging is required to be at 9~12 degrees and 15~17 degrees respectively. However, if the temperature is not well grasped in the extrusion process, or the time of aging is not correct, it will cause trouble of insufficient hardness or over-aging. There are three temperatures that have a great influence on the hardness of aluminum tube forming, one is the temperature of the extrusion tube, that is, the temperature of the extrusion mold, one is the temperature of the aging furnace. The temperature of the aluminum profile must be controlled at no less than 490 degrees. Otherwise, the temperature is too low, after the first cooling, it will not reach the ideal hardness, and will be difficult to reach it when artificial aging.

When manufacturing 6061 the temperature in the aging furnace should be controlled at 175 degrees, and for 6063 which should be at 185 degrees. The aging time of 6061 is 6 hours, and 6063 is about 4~5 hours, so that the aluminum tube can reach the ideal hardness after aging. If the aging time is too long, it is possible to cause aluminum profile annealing, it is possible to cause the whole batch of aluminum scrap. In the aging process, pay attention to the fan’s air distribution, and the aluminum should be placed evenly, so as not to cause uneven hardness after aging.

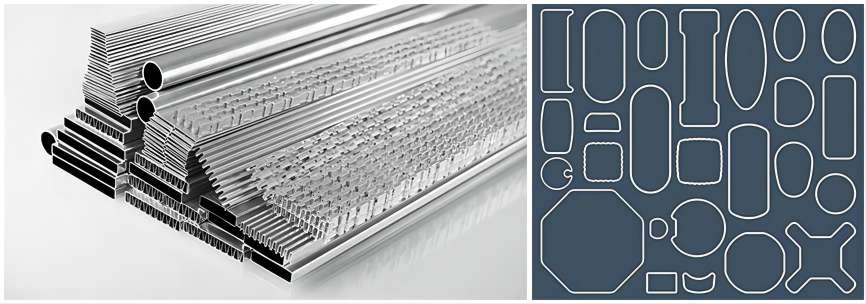

Applications of Aluminum Tube

Aluminum tubes are used in a variety of industries and hobbyists, in a variety of DIY projects and manufacturing and construction fields. In addition, it is widely used in the aerospace industry.

A good example is the 6061-T6 aluminum tube, which is commonly used in the aircraft/aerospace industry due to its strength, weldability and ease of machining. Most all-aluminum tubes can be brazed and welded by all types of welding.

Aluminum and aluminum alloys are the most commonly used metals in the aerospace industry for a variety of reasons. Its relatively low cost, light weight and processability are the main reasons for its widespread use.

Aluminum has good physical characteristics such as no sparking, no magnetism, no electrical, no thermally conductive, and strong chemical resistance. In addition to the aircraft industry, it is also popular for construction and marine applications due to its ease of manufacture, non-toxicity, strength, and corrosion resistance in industrial and marine environments.

Anodizing aluminum can improve its corrosion resistance and obtain a rainbow finish of various colors. Because some alloys can be slightly corrosive, they are coated with a thin layer of aluminum to provide additional protection.

Other Causes Affecting Aluminum’s Hardness

- The aluminum extrusion frame should not be too narrow, and there should be a gap between the material and the material, especially the small thick wall aluminium tubes that are not ventilated. The tube material is placed below, which is conducive to the aging cycle air supply.

- Before the aluminum profiles are loaded into the furnace, other special alloys of 6xxx and the ordinary 6063 alloys shall be loaded separately for aging. When the aging is done in the same furnace due to production reasons, the special alloy process shall be used for aging.

Aluminum at CHAL

No matter which kind of hardness of the aluminum tube you need, CHAL- one of the most professional aluminum tube suppliers– can support you with the best products. We also are able to support you aluminium plates, aluminium foils, aluminium circle, etc. These profiles are widely used in various industries. Also as an OEM aluminum products supplier, our professionals will help you create custom aluminum profiles to meet your needs. Our custom and OEM extrusion services enable us to meet almost any requirements of customers.