Aluminum casting is an essential manufacturing process used across various industries, including automotive, aerospace, construction, and electronics. The ability to produce complex and lightweight parts with excellent mechanical properties makes aluminum casting a preferred method for fabricating high-quality components.

This article provides an in-depth exploration of aluminum casting, including the aluminum casting process, different aluminum casting methods, and how to effectively cast aluminum parts to achieve optimal performance and quality.

What Are Aluminum Casting Parts?

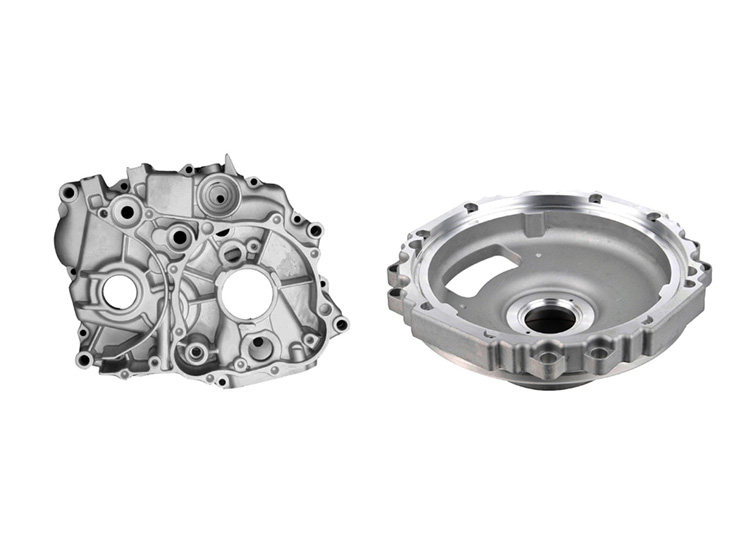

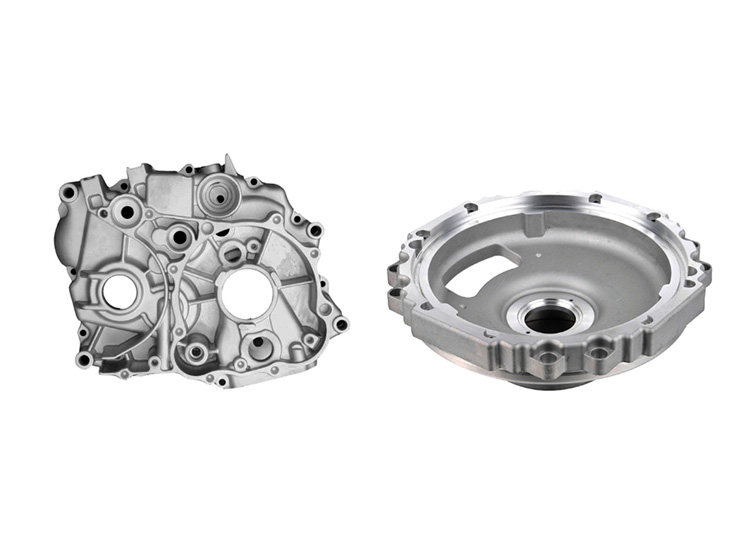

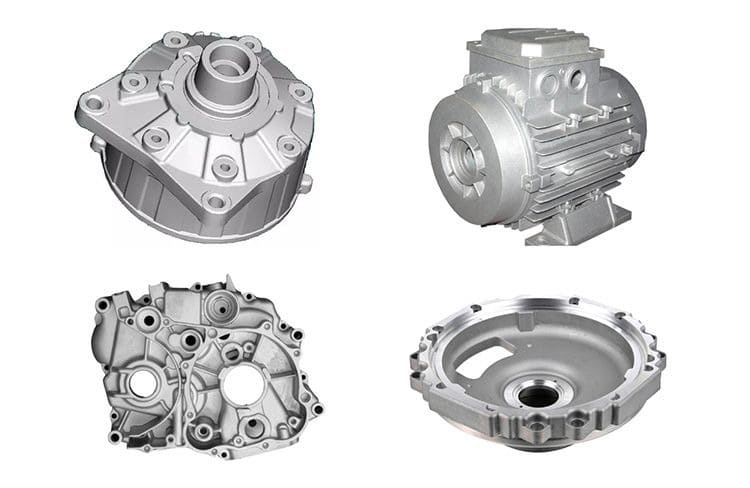

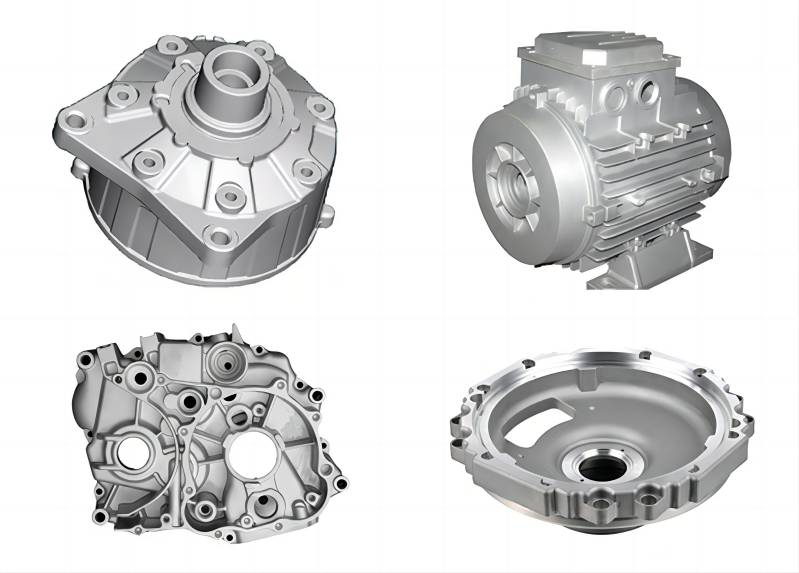

Aluminum casting parts are metal components created by pouring molten aluminum into a mold and allowing it to solidify. These parts are used in various industries due to their strength, lightweight nature, corrosion resistance, and excellent thermal and electrical conductivity.

Advantages of Aluminum Casting

1. Lightweight and High Strength

One of the most significant advantages of aluminum casting is its exceptional strength-to-weight ratio. Aluminum is a low-density metal, making it much lighter than steel or iron while maintaining sufficient strength for structural applications. This property is especially critical in industries such as aerospace and automotive manufacturing, where reducing weight improves fuel efficiency, increases payload capacity, and enhances overall performance.

Aluminum possesses natural corrosion resistance, thanks to its ability to form a thin, protective oxide layer when exposed to air. This oxide layer prevents further oxidation and degradation, making aluminum an excellent material for use in harsh environments, including marine, chemical, and outdoor applications.

3. Excellent Machinability and Workability

Cast aluminum parts can be easily machined, drilled, welded, and finished to achieve precise dimensions and surface finishes. Compared to other metals, aluminum requires less energy and effort for machining, making it a cost-effective choice for high-precision applications. Additionally, aluminum components can be anodized, powder-coated, or painted for added protection and enhanced aesthetic appeal.

4. Superior Thermal and Electrical Conductivity

Aluminum is known for its excellent heat dissipation and electrical conductivity, making it a preferred material for applications that require efficient energy transfer. Its high thermal conductivity allows for rapid heat dissipation, which is crucial in industries where temperature regulation is essential, such as electronics, power transmission, and industrial machinery.

5. 100% Recyclability and Sustainability

Aluminum is a fully recyclable material, meaning it can be melted down and reused multiple times without losing its essential properties. Recycling aluminum requires only 5% of the energy needed to produce primary aluminum from raw ore, significantly reducing environmental impact and manufacturing costs. This makes aluminum casting an eco-friendly choice for industries committed to sustainability and reducing carbon footprints.

Types of Aluminum Casting Processes

Aluminum casting involves different techniques depending on production requirements, part complexity, and cost considerations. The most commonly used aluminum casting processes include:

1. Aluminum Sand Casting

Aluminum sand casting is one of the oldest and most widely used methods for producing aluminum casting parts. The process involves creating a mold using a sand-based mixture, into which molten aluminum is poured. Once the metal solidifies, the mold is broken apart to extract the final casting.

Key Steps in Aluminum Sand Casting

- Pattern Making – A replica of the desired part (typically made of wood, plastic, or metal) is created to shape the sand mold.

- Mold Preparation – Sand mixed with binders is packed around the pattern in a box called a flask. The pattern is then removed, leaving a cavity in the sand.

- Metal Pouring – Molten aluminum is carefully poured into the sand mold cavity.

- Cooling and Solidification – The metal cools and takes the shape of the mold.

- Mold Breaking and Part Extraction – The sand mold is broken apart to retrieve the aluminum casting.

- Finishing Processes – The cast part undergoes trimming, machining, and surface treatments as required.

Advantages of Aluminum Sand Casting:

- Low Cost: Sand molds are inexpensive and can be easily formed, making this method cost-effective for low- to medium-volume production.

- Versatility: Suitable for large, heavy, and intricate components that may be difficult to produce using other casting methods.

- Material Flexibility: Can accommodate a wide range of aluminum alloys.

Applications of Aluminum Sand Casting:

- Automotive Industry: Engine blocks, transmission cases, and cylinder heads.

- Aerospace Industry: Large structural components and housings.

- Industrial Equipment: Pumps, impellers, and machine tool bases.

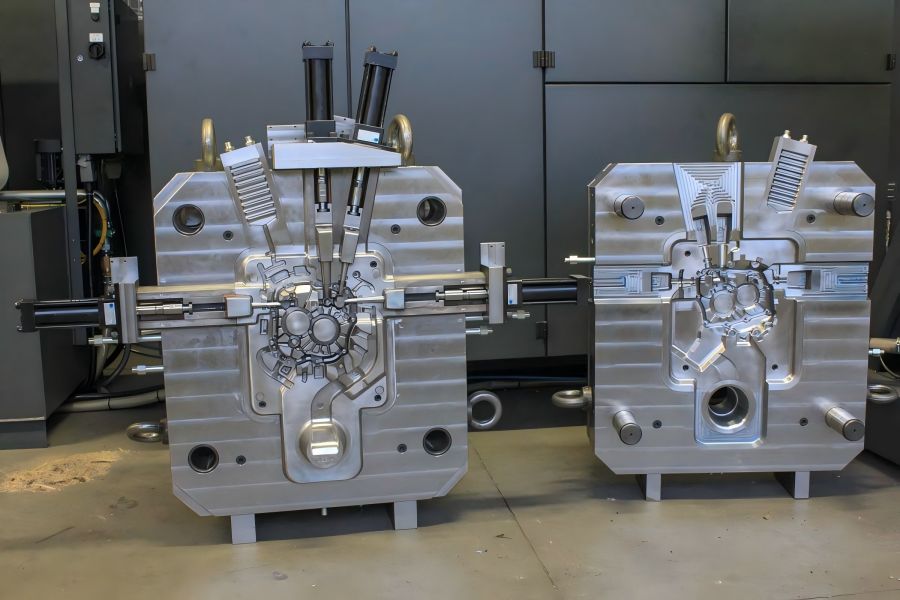

2. Aluminum Die Casting

Aluminum die casting is a high-precision method that involves injecting molten aluminum under high pressure into a steel mold (die). The process is highly efficient and used for producing complex, high-volume aluminum parts with fine details and excellent surface finishes.

Key Steps in Aluminum Die Casting

- Mold Preparation – The metal mold (die) is preheated and coated with a lubricant to prevent sticking.

- Metal Injection – Molten aluminum is injected into the die cavity under high pressure (typically 10-175 MPa).

- Cooling and Solidification – The metal rapidly cools and hardens within the die.

- Ejection and Trimming – The solidified casting is ejected from the die, and excess material is removed.

- Finishing – Additional machining and surface finishing (such as anodizing or painting) may be applied.

Advantages of Aluminum Die Casting:

- High Production Efficiency: Short cycle times and minimal post-processing make it ideal for mass production.

- Excellent Dimensional Accuracy: Produces parts with tight tolerances and complex geometries.

- Smooth Surface Finish: Reduces the need for extensive machining and finishing.

Applications of Aluminum Die Casting:

- Automotive Components: Engine blocks, transmission housings, wheels, and brackets.

- Electronics and Consumer Goods: Smartphone housings, laptop frames, and appliance casings.

- Industrial and Medical Equipment: Precision-machined parts for machinery and medical devices.

3. Aluminum Investment Casting (Lost Wax Casting)

Aluminum investment casting, also known as lost wax casting, is a precision method used to create highly detailed and intricate aluminum parts. The process involves making a wax model, coating it with a ceramic shell, and then removing the wax to leave a cavity for molten aluminum.

Key Steps in Aluminum Investment Casting

- Wax Pattern Creation – A wax replica of the final part is made.

- Shell Coating – The wax pattern is dipped in ceramic slurry multiple times to form a hard shell.

- Dewaxing – The wax is melted and drained, leaving a hollow ceramic mold.

- Metal Pouring – Molten aluminum is poured into the ceramic mold.

- Cooling and Shell Removal – Once the aluminum solidifies, the ceramic shell is broken away.

- Final Processing – The casting is cleaned, machined, and finished as needed.

Advantages of Aluminum Investment Casting:

- Superior Detail and Precision: Produces intricate and complex parts with fine details that other casting methods struggle to achieve.

- Minimal Machining Required: Due to high accuracy, additional machining is often unnecessary.

- Excellent Surface Finish: Results in smooth surfaces with minimal defects.

Applications of Aluminum Investment Casting:

- Aerospace and Defense: Jet engine components, turbine blades, and structural aircraft parts.

- Medical Industry: Surgical tools, prosthetics, and orthopedic implants.

- High-Precision Industrial Components: Valve bodies, pump housings, and intricate mechanical parts.

4. Aluminum Gravity Die Casting

Aluminum gravity die casting, also known as permanent mold casting, involves pouring molten aluminum into a reusable metal mold using gravity, without applying external pressure. This method is used for medium to high-volume production of parts with good mechanical properties.

Key Steps in Aluminum Gravity Die Casting

- Mold Preparation – A permanent metal mold (die) is coated with a refractory material to improve part release and durability.

- Metal Pouring – Molten aluminum is poured into the mold, relying on gravity to fill the cavity.

- Cooling and Solidification – The aluminum gradually cools and solidifies into the mold shape.

- Part Removal – Once cooled, the casting is removed, and the mold is cleaned for reuse.

- Finishing Operations – The casting may undergo trimming, machining, or additional surface treatments.

Advantages of Aluminum Gravity Die Casting:

- Higher Mechanical Strength: The slow cooling process results in denser and stronger aluminum castings compared to sand casting.

- Good Dimensional Accuracy: Offers better precision than sand casting but lower than die casting.

- Reusable Molds: Reduces production costs for medium-to-high-volume manufacturing.

Applications of Aluminum Gravity Die Casting:

- Automotive Industry: Engine blocks, cylinder heads, and suspension components.

- Electronics and Heat Management: Heat sinks, LED housings, and radiator components.

- Household and Industrial Equipment: Gas burners, cookware, and heavy-duty machinery parts.

How to Cast Aluminum Parts: Step-by-Step Process

Here’s a detailed Step-by-Step Process for casting aluminum parts:

| Step | Description | Key Considerations |

| 1. Selecting the Right Aluminum Alloy | Choose an aluminum alloy based on the required strength, corrosion resistance, and thermal properties. Common alloys include A356 (high strength, excellent castability), 6061 (strong, corrosion-resistant), and 319 (used in automotive applications). | The alloy selection depends on the part’s function, mechanical requirements, and operating environment. |

| 2. Mold Preparation | Prepare the mold using sand, metal, or ceramic materials, depending on the chosen casting method. Ensure the mold has proper gating and venting systems to allow smooth metal flow and prevent defects. | For die casting, reusable steel molds are used. For sand casting, the mold must be broken after each use. For investment casting, ceramic shells are used for fine details. |

| 3. Melting the Aluminum | Heat aluminum in a furnace until it reaches a liquid state (around 660°C / 1220°F). Remove impurities and trapped gases by using degassing agents and fluxes. | Proper temperature control prevents porosity, oxidation, and inclusions in the final casting. |

| 4. Pouring the Molten Aluminum | Carefully pour the molten aluminum into the mold cavity, ensuring even distribution and preventing air entrapment. In die casting, the metal is injected under high pressure. In sand casting and gravity die casting, gravity is used for filling the mold. | Use proper gating and risers to ensure smooth flow and avoid cold shuts (incomplete filling) and air pockets. |

| 5. Cooling and Solidification | Allow the aluminum to cool and solidify inside the mold. This step determines the part’s microstructure and mechanical properties. Controlled cooling prevents internal stresses and defects. | Rapid cooling (quenching) improves strength, while slow cooling can prevent warping or cracking. |

| 6. Removing the Casting from the Mold | After solidification, extract the aluminum part from the mold. In sand casting, the mold is broken to retrieve the part. In die casting and investment casting, the mold is opened or removed without damage. | Care must be taken to avoid deformations or fractures when removing the part from the mold. |

| 7. Finishing and Post-Processing | Trim excess material, remove gating systems, and apply surface treatments. Machining, polishing, powder coating, anodizing, or heat treatment may be required. | Finishing improves dimensional accuracy, strength, and aesthetics of the final part. |

| 8. Quality Inspection | Conduct visual, dimensional, and non-destructive testing (X-ray, ultrasonic, or dye penetrant inspection) to detect internal and external defects. | Ensures the final part meets industry standards and specifications for strength, durability, and precision. |

Common Aluminum Casting Defects and Solutions

During the aluminum casting process, defects may arise that impact the quality of the final product. Below are some common issues and solutions:

| Defect | Cause | Solution |

| Porosity (Gas Holes) | Trapped air, improper degassing | Use proper venting, degassing agents, and controlled pouring techniques |

| Shrinkage | Uneven cooling, inadequate feeding | Optimize mold design, use risers to compensate for shrinkage |

| Cracks | Rapid cooling, thermal stress | Adjust cooling rate, apply heat treatment |

| Misruns (Incomplete Filling) | Low pouring temperature, slow metal flow | Increase metal temperature, optimize gating system |

Aluminum casting is a versatile and efficient method for producing high-quality metal parts with various applications across industries. By understanding the aluminum casting process, choosing the right aluminum casting methods, and implementing best practices, manufacturers can optimize production efficiency and ensure superior aluminum casting parts.

With advancements in casting technology, aluminum continues to be a leading material in engineering and industrial applications. Whether for industrial applications or custom manufacturing, mastering aluminum casting techniques allows for cost-effective and precision-driven production.