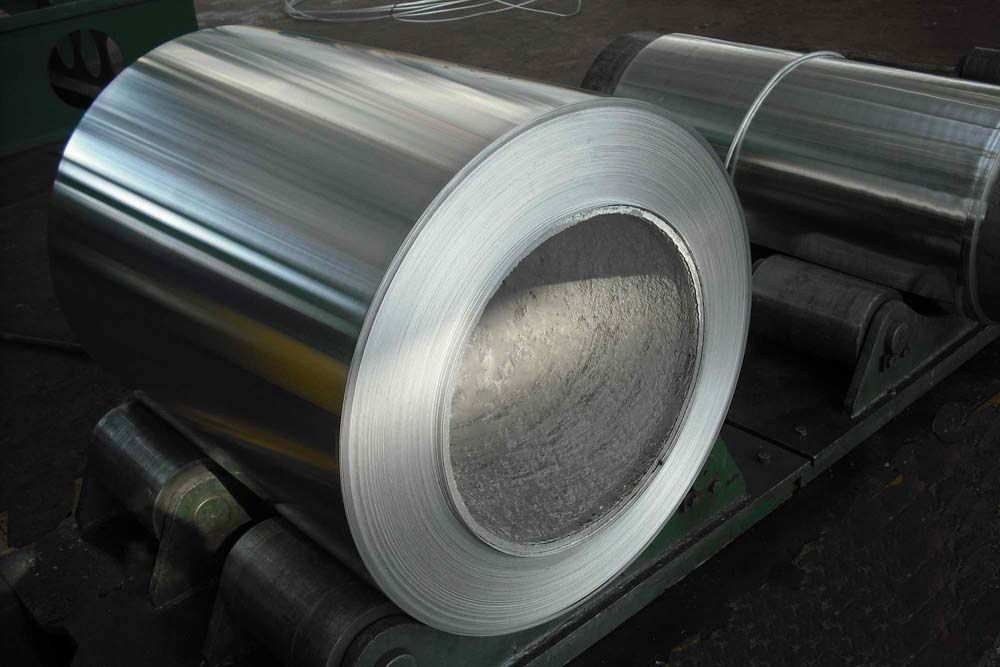

Do you know aluminum coils? Have you heard of the 3003 aluminum coil? 1050 aluminum coil? 6061 aluminum coil? What do they mean? Why are there so many types of aluminum coils? How should I choose? This article will introduce you in detail to why there are so many models of aluminum coils.

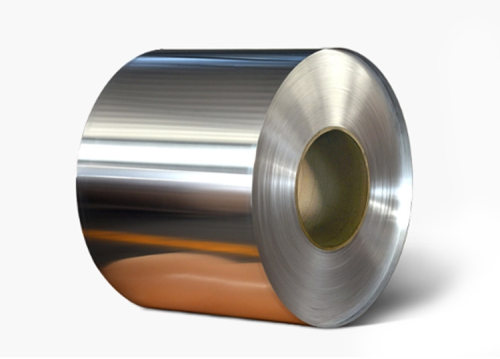

An aluminum coil (aluminum coil) is a metal product for flying shear after rolling and bending corner processing by casting and rolling mill. Aluminum coil is a metal material widely used in electronics, packaging, construction, machinery, and other fields. At present, according to the different metal elements contained in aluminum coils, aluminum coils are roughly divided into 9 categories, namely 9 series.

Aluminum Coil Classification

1000 Series Aluminum Coil

The 1000 series aluminum coil represents the 1000 series aluminum sheet, which is also called a pure aluminum sheet. Among all the series, the 1000 series belongs to the series with the most aluminum content. The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is currently the most commonly used series in conventional industries. Most of the products circulating in the market are the 1050 and 1060 series. The 1000 series aluminum plate determines the minimum aluminum content of this series according to the last two Arabic numerals. For example, the last two Arabic numerals of the 1050 series are 50. According to the international brand naming principle, the aluminum content must reach 99.5% or more to be a qualified product.

2000 Series Aluminum Coil

2000 series aluminum coils represent 2A16 (LY16), 2A06 (LY6); 2000 series aluminum plates are characterized by high hardness, of which the copper element content is the highest, about 3-5%. 2000 series aluminum plates are aviation aluminum materials, which are not often used in conventional industries.

3000 Series Aluminum Coil

The representative of 3000 series aluminum coil is mainly 3003, 3003, 3A21. It can also be called an anti-rust aluminum plate. The 3000 series aluminum plate is made of manganese as the main component. And China’s 3000 series aluminum plates are relatively outstanding in the market.

4000 Series Aluminum Coil

The representative of the 4000 series aluminum coil is 4A01, 4000. This series of aluminum plates belong to the series with the higher silicon content. Usually, the silicon content is between 4.5-6.0%. 4000 series aluminum coil belongs to construction materials, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance, and has the characteristics of heat resistance and wear resistance.

5000 Series Aluminum Coil

The representative of 5000 series aluminum coil is 5052, 5005, 5083, 5A05 aluminum coil. The 5000 series aluminum plate belongs to the more commonly used alloy aluminum plate series, the main element is magnesium, and the magnesium content is between 3-5%. It can also be called an aluminum-magnesium alloy. The main features are low density, high tensile strength, and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than other series. Therefore, it is commonly used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industries. The processing technology is continuous casting and rolling, which belongs to the hot-rolled aluminum plate series, so it can be used for deep oxidation processing.

6000 Series Aluminum Coil

The representative of 6000 series aluminum coil is 6061. It mainly contains two elements of magnesium and silicon, so it concentrates the advantages of 4000 series and 5000 series 6061 is a cold-treated aluminum forged product, suitable for applications with high requirements for corrosion resistance and oxidation. Good workability, excellent interface characteristics, easy coating, and good processability. It can be used on low-pressure weapons and aircraft joints.

The general characteristics of 6061 aluminum coil: excellent interface characteristics, easy coating, high strength, good workability, and strong corrosion resistance.

Typical uses of 6061 aluminum: aircraft parts, camera parts, couplers, marine accessories and hardware, electronic accessories and joints, decorative or various hardware, hinge heads, magnetic heads, brake pistons, hydraulic pistons, electrical accessories, valves, and valve parts.

7000 Series Aluminum Coil

The representative of 7000 series aluminum coil is 7075. It mainly contains zinc. It also belongs to the aviation series. It is an aluminum-magnesium-zinc-copper alloy, a heat-treatable alloy, and a super hard aluminum alloy with good wear resistance. The 7075 aluminum plate is stress-relieved and will not be deformed or warped after processing. All super The thick 7075 aluminum plates are all ultrasonically detected, which can ensure that there are no blisters and impurities. The 7075 aluminum plate has high thermal conductivity, which can shorten the forming time and improve work efficiency. The main feature is that the hardness of 7075 is a high-hardness, high-strength aluminum alloy, which is often used in the manufacture of aircraft parts. It requires the manufacture of high-stress structural parts and molds with high strength and strong corrosion resistance.

8000 Series Aluminum Coil

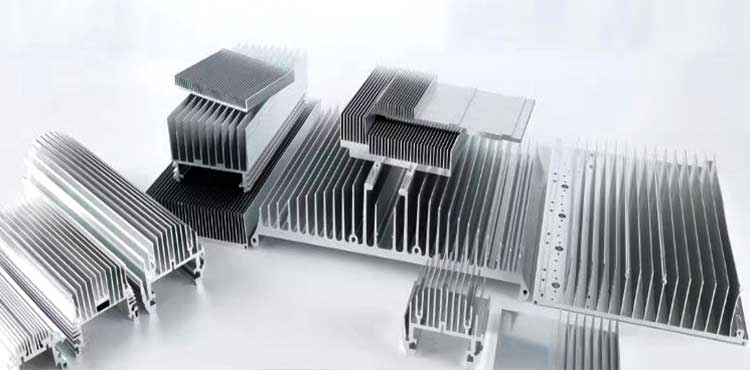

The more commonly used in 8000 series aluminum coil is 8011. It is an aluminum plate whose main function is to make bottle caps, and it is also used in radiators, most of which are aluminum foil.

9000 Series Aluminum Coil

The 9000 series of aluminum coils belong to the spare series, and the technology is so advanced. To cope with the emergence of aluminum plates containing other alloy elements, the International Aluminum Strip Federation has indicated that the 9000 series is spare, waiting for another new variety to appear to fill the gap of the 9000 series.

The Key to Choosing Aluminum Coil

When we choose aluminum coils, it should be noted that choosing the right aluminum coil alloy directly depends on the performance and specific use scenarios. Before buying aluminum coils, you must pay attention to liquidity:

- Tensile strength

- Thermal conductivity

- Weldability

- Formability

- Corrosion resistance

For most companies that need aluminum coils as raw materials for secondary processing, the key to choosing high-quality aluminum coils is to choose a good aluminum coil supplier. My recommendation is CHAL Aluminium Corporation. CHAL is a professional supplier of aluminum coils. The price advantage of aluminum coils has always been an important reason why Chal has been welcomed by customers from all over the world. Provide high-quality aluminum coils from China to customers all over the world. If you want to buy high-quality aluminum coils, you can consult the sales staff of Chal, they will give you high-quality services and meet your requirements. If you want to buy high-quality aluminum coils, you can consult the sales staff of Char, they will give you high-quality service and recommend the aluminum coils that are suitable for you.