Selecting the appropriate aluminum foil duct is crucial for ensuring optimal performance and safety in various applications, particularly in HVAC systems and kitchen ventilation. The right choice can enhance airflow efficiency, reduce energy costs, and ensure longevity. This article will guide you through understanding aluminum foil ducts, the factors to consider when choosing them, and recommend a reliable aluminum foil duct supplier.

What are Aluminum Foil Ducts?

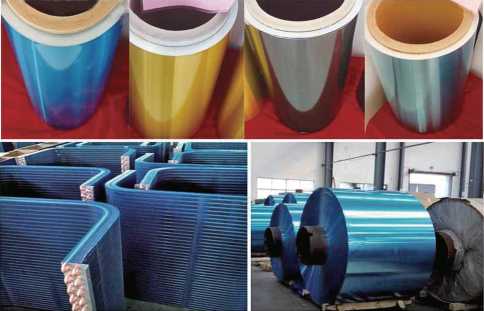

Aluminum foil ducts are typically constructed with a layer of aluminum foil laminated to a polyester film. This design harnesses the excellent thermal conductivity, corrosion resistance, and lightweight properties of aluminum, making these ducts essential components in various ventilation and air handling systems. They offer a combination of flexibility, durability, and efficiency. In this section, we will explore the different types of aluminum foil ducts, their unique characteristics, and their common applications to help you make an informed decision.

Types of Aluminum Foil Ducts

Aluminum foil ducts come in various types, each designed for specific applications and environments. Below are the common types of aluminum foil ducts and the typical grades associated with them:

1. Standard Aluminum Foil Ducts

These are the basic, uninsulated ducts commonly used for general ventilation and exhaust applications.

Typical Grades:

1100 Aluminum foil: Nearly pure aluminum, known for excellent corrosion resistance and high thermal conductivity.

2. Insulated Aluminum Foil Ducts

These ducts have an additional layer of insulation, which helps maintain the temperature of the air being transported and reduces energy loss.

Typical Grades:

3003 Aluminum foil: Aluminum alloyed with manganese, offering good corrosion resistance and moderate strength.

8011 Aluminum foil: Aluminum with iron and silicon, providing high corrosion resistance and good strength.

3. Flexible Aluminum Foil Ducts

These ducts are highly flexible and can be easily maneuvered around obstacles, making them ideal for tight spaces and complex installations.

Typical Grades:

1100 Aluminum foil: Nearly pure aluminum, providing excellent flexibility and corrosion resistance.

3003 Aluminum foil: Adds moderate strength while maintaining good flexibility.

4. Semi-Rigid Aluminum Foil Ducts

These ducts offer a balance between flexibility and rigidity, making them suitable for applications that require both durability and some degree of maneuverability.

Typical Grades:

5052 Aluminum foil: Aluminum alloyed with magnesium and chromium, known for its high strength and excellent corrosion resistance.

Unique Characteristics of Aluminum Foil Ducts

- Thermal Conductivity: Aluminum foil’s high thermal conductivity ensures efficient heat transfer, making these ducts ideal for heating and cooling applications.

- Corrosion Resistance: The natural resistance of aluminum to corrosion prolongs the lifespan of the ducts, especially in moist or chemically reactive environments.

- Lightweight: The low density of aluminum makes these ducts easy to handle and install, reducing labor costs and installation time.

- Flexibility: Flexible and semi-rigid options provide versatile solutions for various installation scenarios, including tight spaces and complex layouts.

- Durability: Aluminum foil ducts are robust and can withstand physical stresses, making them suitable for both residential and commercial applications.

Common Applications of Aluminum Foil Ducts

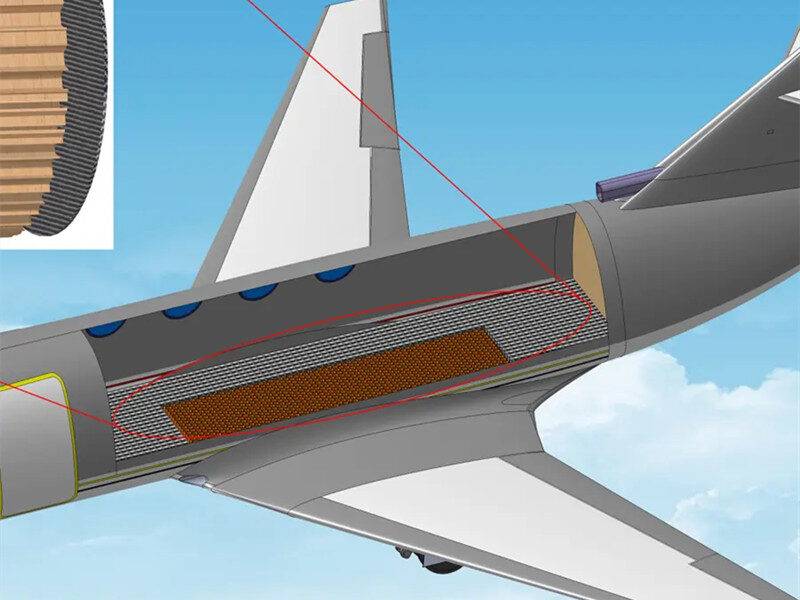

- Residential HVAC Systems: Used in heating, ventilation, and air conditioning systems to ensure efficient airflow and temperature regulation.

- Dryer Vents: Facilitate the safe expulsion of moist air from clothes dryers, preventing mold growth and ensuring proper drying.

- Commercial Ventilation: Employed in commercial buildings to provide adequate ventilation and maintain indoor air quality.

- Exhaust Systems: Utilized in kitchens, bathrooms, and industrial settings to remove unwanted odors, smoke, and contaminants from the air.

Typical Applications for Each Type

| Grade | Composition | Properties | Applications |

| 1100 aluminum foil | Nearly pure aluminum (99% or more) | Excellent corrosion resistance, High thermal and electrical conductivity, Good workability | HVAC systems, Kitchen ventilation, General applications requiring high ductility and corrosion resistance |

| 3003 aluminum foil | Aluminum with ~1.2% manganese | Good corrosion resistance, Moderate strength, Excellent workability | General ventilation, Exhaust applications, Applications requiring a balance of strength and flexibility |

| 5052 aluminum foil | Aluminum with 2.2%-2.8% magnesium and 0.15%-0.35% chromium | High strength, Excellent corrosion resistance, Good workability | Industrial ventilation systems, Environments with higher stress and load requirements |

| 8011 aluminum foil | Aluminum with a small amount of iron and silicon | High corrosion resistance, Good strength, Excellent workability | Household and industrial foil products, Some aluminum foil duct applications requiring flexibility and barrier properties |

By understanding the types and typical grades of aluminum foil ducts, you can select the appropriate duct for your specific needs, ensuring optimal performance and efficiency in your ventilation or air handling system.

Factors to Consider When Choosing Aluminum Foil Ducts

Selecting the right aluminum foil duct involves considering various factors to ensure optimal performance and longevity. Here are the key factors to consider:

1. Size and Diameter

The size and diameter of the duct must match the requirements of your system to ensure proper airflow and efficiency.

Considerations: Measure the diameter of your existing ductwork or vent openings to ensure compatibility. Oversized or undersized ducts can lead to airflow issues and reduced system efficiency.

2. Length and Flexibility

The length and flexibility of the duct impact its ease of installation and ability to navigate around obstacles.

Considerations: Determine the required length for your installation and choose a duct that offers the necessary flexibility. Flexible ducts are ideal for tight spaces, while semi-rigid ducts provide more durability for straight runs.

3. Durability and Strength

Durable and strong ducts are less prone to damage and can withstand various environmental conditions.

Considerations: Look for ducts made from high-quality aluminum grades known for their strength and durability, such as Grade 5052 or Grade 6061. Thicker materials generally offer better resistance to wear and tear.

4. Thermal Insulation

Insulated ducts help maintain the temperature of the air being transported, reducing energy loss and improving system efficiency.

Considerations: For applications where thermal insulation is crucial, such as HVAC systems, choose ducts with an additional layer of insulation. Insulated ducts are especially important in environments with significant temperature variations.

5. Fire Resistance

Fire-resistant ducts enhance safety by preventing the spread of fire through ductwork.

Considerations: Ensure the ducts meet fire safety standards and certifications. Fire-resistant ducts are crucial for applications in high-heat environments, such as kitchen ventilation systems.

6. Corrosion Resistance

Corrosion-resistant ducts have a longer lifespan and are better suited for environments with high moisture or exposure to chemicals.

Considerations: Aluminum grades such as 1100 and 3003 offer excellent corrosion resistance. For harsher environments, consider higher-grade options like 5052 or 6061.

7. Cost and Budget

Balancing cost with performance ensures you get the best value without compromising on quality.

Considerations: Compare prices of different duct options while considering their performance and durability. Investing in high-quality ducts can reduce maintenance costs and improve system efficiency over time.

8. Ease of Installation

Easy-to-install ducts save time and effort during setup and maintenance.

Considerations: Flexible ducts are typically easier to install, especially in complex or confined spaces. Ensure the ducts come with installation instructions and any necessary accessories.

By considering these factors, you can select the right aluminum foil duct that meets your specific needs, ensuring efficient and reliable performance in your ventilation or air handling system.

Get Aluminum Foil Ducts from CHAL

CHAL is a reputable supplier of high-quality aluminum foil ducts, offering a wide range of products to meet various needs. Here’s why you should consider CHAL for your aluminum foil duct requirements:

- Wide Selection: CHAL provides a diverse range of aluminum foil ducts, including standard, insulated, flexible, and semi-rigid options.

- Quality Assurance: All products undergo rigorous quality checks to ensure durability, efficiency, and safety.

- Expert Advice: CHAL’s team of experts can help you choose the right duct based on your specific needs and applications.

- Competitive Pricing: CHAL offers cost-effective solutions without compromising on quality.

- Customer Support: Excellent customer service to assist with installation, maintenance, and troubleshooting.

Choosing the right aluminum foil duct is essential for efficient and safe operation in various applications. By understanding the different types, considering key factors, and selecting a reliable supplier like CHAL, you can ensure optimal performance and longevity for your ducting needs.

For more information and to explore CHAL’s range of aluminum foil ducts and other aluminum products, visit CHAL’s official website.