Aluminum strips are a new type of environmentally friendly building material product made of high-purity aluminum, which has the characteristics of corrosion resistance. The aluminum strip is an essential material for making insulating glass, so the quality of the aluminum strip is closely related to the use effect of the glass. So how to choose the right and good quality aluminum strips?

Usually, the raw material of aluminum strips is high-purity aluminum, which is made after surface treatment. The aluminum strip is used with insulating glass and has good compatibility. You can choose aluminum strips from the following aspects:

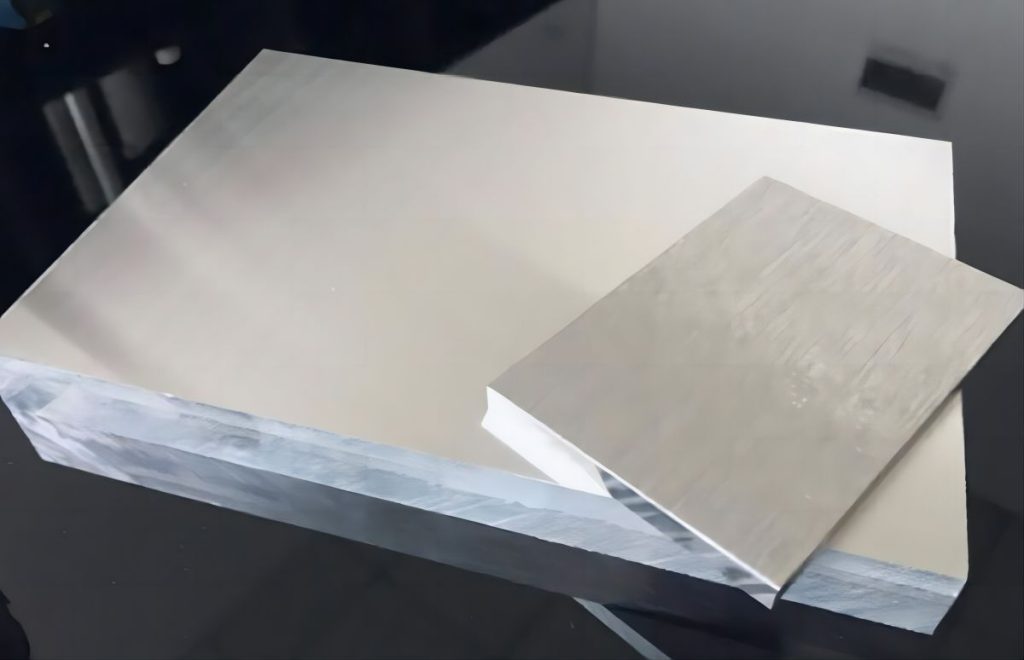

Choose the exterior of aluminum strips

The hollow aluminum strip is mainly to separate the hollow glass and play an effective supporting role, so the surface of the aluminium strip needs to be flat without obvious oil stains. Besides, the aluminum strip must be straight and cannot be bent.

Choose the right type of aluminum strips

Aluminum strips are divided into high-frequency welding aluminum strips and cold drew aluminum strips. Due to the low oxidation resistance of cold-drawn aluminum strips and their unsightly appearance. The cold-drawn aluminum strip is gradually replaced by high-frequency welding aluminum strips. So it is not recommended to buy cold-drawn aluminum strips.

Choose the right width of aluminum strips

The width of the aluminum strips on the market is between 5.5mm and 26.5mm, and the appropriate specification should be selected according to the size of the insulating glass. In most cases, the specification of x.5 is more commonly used, such as 5.5A, 8.5A, and 11.5A.

Choose the right wall thickness for aluminum strips

Wall thickness refers to the thickness of the inner wall of the aluminum strip, which can be divided into bending and non-bending. The thickness of the unbendable aluminum strip is 0.2mm-0.29mm. The thickness of the bendable aluminum strip is 0.3mm-0.35mm. The thicker the aluminum strip, the less the bending loss.

In addition, the thickness of the aluminum strip is 0.2mm-0.25mm, and the aluminum strip within this specification range is manually operated, which can save costs. Aluminum strips with a thickness of 0.23mm-0.29mm can be used both by hand and by machine. For machines and sheets, it is recommended to use aluminum strips with a thickness of 0.21mm or more. Aluminum strips with a thicker wall have better toughness and are less likely to be damaged by machines.

Choose the right height for aluminum strips

The height of the aluminum strip is fixed between 5.5mm-7mm. The higher the height, the thicker the aluminum strip. The international standard height of aluminum strips is 7mm with an error of +-0.025mm.

CHAL aluminum strips have the height of international standard and perfect cross-section, and the surface is bright, beautiful, and generous, with double rows of holes on one side to ensure the activity of the desiccant. CHAL strictly controls the procurement and production errors of raw materials, with no deformation, and accurate and stable dimensions, from product quality to product appearance are perfect. Aluminum strips are anti-rust, anti-corrosion, and high in brightness. The surface of the aluminum strip has uniform pores, good straightness, no deformation, and stable dimensions. Aluminum strips are high strength and have good toughness.