What is an extruded aluminum heat sink?

An extruded aluminum heat sink is a thermal management device that is used to dissipate heat away from electronic components. It is made by extruding aluminum metal through a die. This extrusion process allows for a wide range of heat sink sizes and shapes, making it possible to create customized designs that are optimized for specific applications. Extruded aluminum heat sinks are popular due to their cost-effectiveness, versatility, and ease of customization. They are used in a wide range of electronic devices, including computers, televisions, LED lighting, and power supplies, among others. The fins of extruded aluminum heat sinks can be further modified to adjust the heat transfer characteristics, depending on the cooling requirements of the electronic device.

The aluminum heat sink extrusion is a highly effective and efficient thermal management solution. When it comes to selecting an extruded aluminum heat sink, one of the most critical factors to consider is the size of the heat sink. The size of the heat sink plays a crucial role in determining its effectiveness in dissipating heat away from electronic components. Choosing the right size heat sink can help prevent overheating, extend the lifespan of the electronic device, and improve its overall performance.

What are the factors need to consider before choosing the Right Extruded Aluminum Heat Sink?

When choosing the right extruded aluminum heat sink for your electronic device, there are several factors to consider. These include:

- Heat dissipation requirements: The heat dissipation requirements of the electronic device will determine the size of the heat sink needed. Devices that generate more heat will require a larger heat sink to dissipate that heat efficiently.

- Available space: The available space in the device will also play a role in determining the size of the heat sink. It is important to choose a heat sink that can fit into the available space without obstructing other components.

- Airflow: The airflow around the heat sink is critical for effective heat dissipation. The size and shape of the fins on the heat sink will affect the airflow, so it is important to consider the airflow requirements of the device when choosing a heat sink.

- Thermal conductivity: The thermal conductivity of the heat sink material will also affect its effectiveness in dissipating heat. Aluminum is an excellent thermal conductor, making it a popular choice for heat sinks.

- Ambient temperature: The ambient temperature of the device’s environment will affect the heat dissipation requirements. Devices that operate in hotter environments will require larger heat sinks to dissipate heat effectively.

- Power dissipation: The amount of power that the device consumes will affect the amount of heat generated, which in turn will determine the size of the heat sink needed.

By considering these factors, you can choose an extruded aluminum heat sink that is the right size for your electronic device and provides optimal thermal management.

What are the types and applications of extruded aluminum heat sinks?

There are several types of extruded aluminum heat sinks available, each with its own unique design and characteristics. Choosing the right type of heat sink will depend on the specific heat dissipation requirements of the electronic device, as well as other factors such as available space and airflow. Here are some common types of extruded aluminum heat sinks and how to choose them for different occasions:

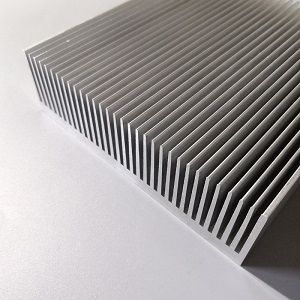

- Straight Fin Heat Sink: This type of heat sink has fins that run perpendicular to the base of the heat sink, providing efficient heat dissipation in a vertical direction. Straight fin heat sinks are best suited for applications where the airflow is limited to a single direction, such as in desktop computers or servers.

- Cross-Cut Heat Sink: This heat sink has fins that are cut into the base of the heat sink in a cross-cut pattern, providing increased surface area for heat dissipation. Cross-cut heat sinks are ideal for applications where the airflow is limited, but the heat dissipation requirements are high, such as in LED lighting or power supplies.

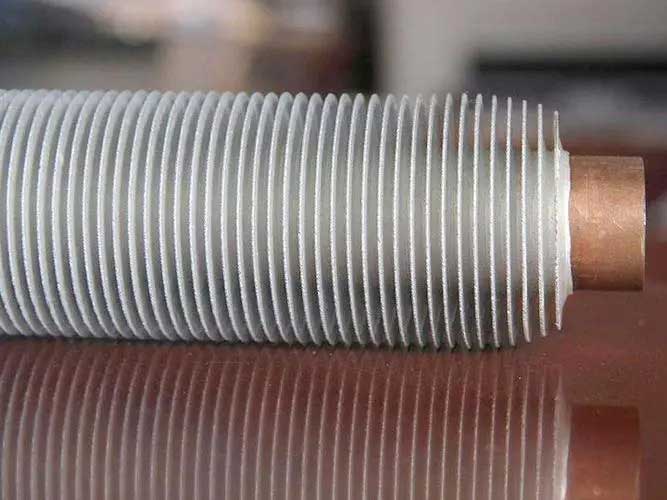

- Pin Fin Heat Sink: This heat sink has pins that extend from the base of the heat sink, providing increased surface area for heat dissipation. Pin fin heat sinks are best suited for applications where there is ample airflow, such as in outdoor LED lighting or in automotive cooling systems.

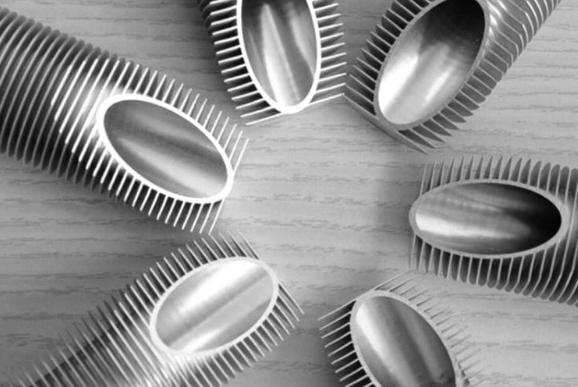

- Elliptical Fin Heat Sink: This heat sink has elliptical fins that provide increased surface area for heat dissipation while maintaining a low profile. Elliptical fin heat sinks are best suited for applications where space is limited, such as in mobile devices or thin laptop computers.

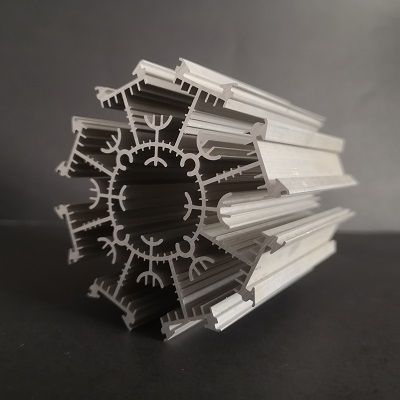

- Omni-Directional Heat Sink: This heat sink has fins that are angled in multiple directions, providing efficient heat dissipation in all directions. Omni-directional heat sinks are ideal for applications where the airflow is unrestricted, such as in large electronic enclosures or in industrial machinery.

When choosing the right type of extruded aluminum heat sink for different occasions, it is important to consider the specific heat dissipation requirements of the device, as well as available space and airflow. By selecting the right type of heat sink, you can ensure efficient and effective thermal management for your electronic device.

By following the guidelines outlined in this article, you can make an informed decision when selecting an extruded aluminum heat sink. Remember to carefully assess your specific requirements and to work with a reputable supplier who can provide expert guidance and support throughout the process.

Believe CHAL is your best choice. We are a professional aluminium heat sink manufacturer in standard and custom-designed aluminum heat sinks. We provide customers with a full range of services, including design to production, technical support, quick delivery, and a large selection of high-quality products that are always in stock and available at the most affordable prices. Please feel free to contact us.

Related Products

Related Articles