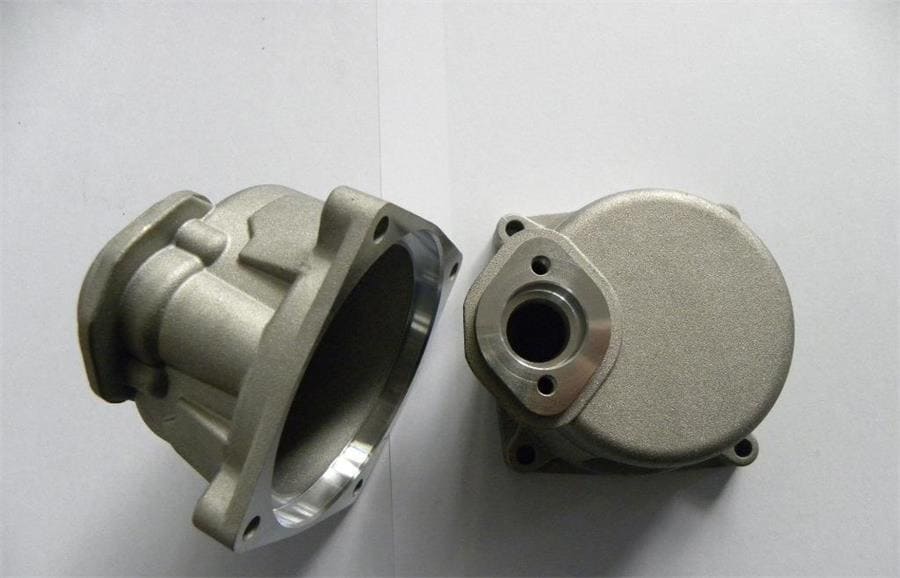

Aluminium fin heat exchanger tube, which is widely used in various fields, enables our products to be better used in all aspects. Because plate-fin heat exchangers have a series of advantages such as flexible volume change and good heat exchange effect, they are widely used in medicine, aviation, aerospace, automobile manufacturing, petrochemical, low-temperature refrigeration, construction machinery, general machinery and other fields. widely.

Why Choose Aluminium for Heat Exchanger Metals?

Compared with stainless steel, aluminum profiles have the characteristics of easy processing. If reasonable planning is required, they can be easily assembled to reduce the need for machining. Moreover, the cost of the aluminum formwork is lower and the heat transfer efficiency is better. If the plate-fin heat exchanger is made of aluminum, it has good heat transfer efficiency and good heat transfer efficiency. It is more convenient and reasonable in the process of use.

Applicable Temperature Range of Aluminium Heat Exchanger

The applicable temperature range is -270℃~+200℃. Since the aluminum plate-fin heat exchanger adopts the brazing process to tightly braze the fins and the partitions together, it bears high pressure, and some large plate-fin heat exchangers The heat exchanger can reach 8MPa.

Aluminium Heat Exchanger Operation Principle

The effect of the aluminum plate-fin heat exchanger is to achieve a good effect of heat dissipation, so that the temperature can be dissipated faster. Improve the pressure bearing capacity of the plate heat exchanger, and because the liquid is in a turbulent state, it can reduce the formation of sediment or dirt, and play a certain “self-cleaning” role. Gasket: Installed in the gasket groove along the periphery of the plates to seal the periphery between the plates to prevent the fluid from leaking out, and seal part of the corner holes according to the design requirements, so that the cold and hot liquids flow according to their respective channels.

Knowing the workable temperature range of aluminium heat exchanger, do you what are the reasoning? Please keep on reading.

What are the Reasons Affecting Heat Exchanging Effect?

The plate heat exchanger is composed of a group of corrugated metal plates with four corner holes for the passage of two liquids for heat transfer. The flow channel gap of the plate heat exchanger is small (2.5-6mm), and the particles larger than 1.5-3mm in diameter are easy to block the plate channel, which makes the pressure drop of the equipment deteriorate sharply, and the heat exchange capacity of the equipment is greatly reduced due to blockage. Seriously cause the continuous production interruption of the device. Due to a large number of impurities in the circulating water, similar devices E208/E209 have been blocked many times, resulting in the frequent shutdown of the device, which has a certain impact on the economic benefits of the enterprise. Later, an easily removable and washable filter was added before the E208/E209 to ensure the long-term operation of the E208/E209.

How to Improve Heat Exchange Rate?

Therefore, a coarse filter or a backwashing device can be installed at the inlet of the medium as required, which can effectively prevent the blockage of the plate heat exchanger. Erosion Corrosion Erosion corrosion is a type of corrosion in which the corrosion process is accelerated due to the relative motion between the medium and the metal surface. Selective corrosion The phenomenon that an element in the alloy preferentially enters the medium due to corrosion is called selective corrosion. Pitting Corrosion Concentrating on individual small points on the metal surface is called pitting corrosion, or small hole corrosion and pitting corrosion. Intergranular corrosion is a kind of corrosion that preferentially corrodes the grain boundaries of metals or alloys and the regions near the grain boundaries, while the grain itself corrodes less.

The gradual popularization of heat exchangers in the use process is to promote the heat dissipation of the machine and controls the degree of pressure change of the equipment. When using the heat exchanger, it is also necessary to check the equipment to prevent the blockage caused by the abnormal use of the equipment from affecting the heat exchange. the cooling effect of the device. The water quality of the circulating water also needs to have corresponding requirements, and more impurities in the water will also affect the effect of heat transfer. In order to effectively prevent the blockage of the equipment, the machinery and equipment can be cleaned regularly.

Advantages of Aluminium Heat Exchanger

1. High heat transfer efficiency

Due to the unique structure of the fin: the fin area is small and the volume is thin, which can cause disturbance to the medium, so that the thermal boundary layer is continuously broken and renewed, the convection heat release coefficient of the fluid is enhanced, and the heat can be dissipated more quickly.

2. Compact structure and light weight.

Aluminum Plate Fin Heat Exchanger

The heat transfer area per unit volume of the aluminum plate-fin heat exchanger is generally 1500-2500m2/m3, which is equivalent to 8 to 20 times that of the shell and tube heat exchanger. The weight is only one tenth of the shell and tube heat exchanger with the same heat exchange area, and the metal consumption per unit heat transfer area can be dozens of times smaller than that of the shell and tube heat exchanger.

3. Wide range of adaptation

Plate-fin heat exchangers can be used for heat exchange of various media between gas-gas, gas-liquid, and liquid-liquid, and can also be adapted to countercurrent, cross-flow, multi-stream, Heat transfer in different working conditions such as multiple processes.

CHAL aluminum is a professional supplier of aluminum products, aluminum heat exchanger is one of our best products, if you are looking for aluminum heat exchanger resources, please look no further, contact us, and get what you want.