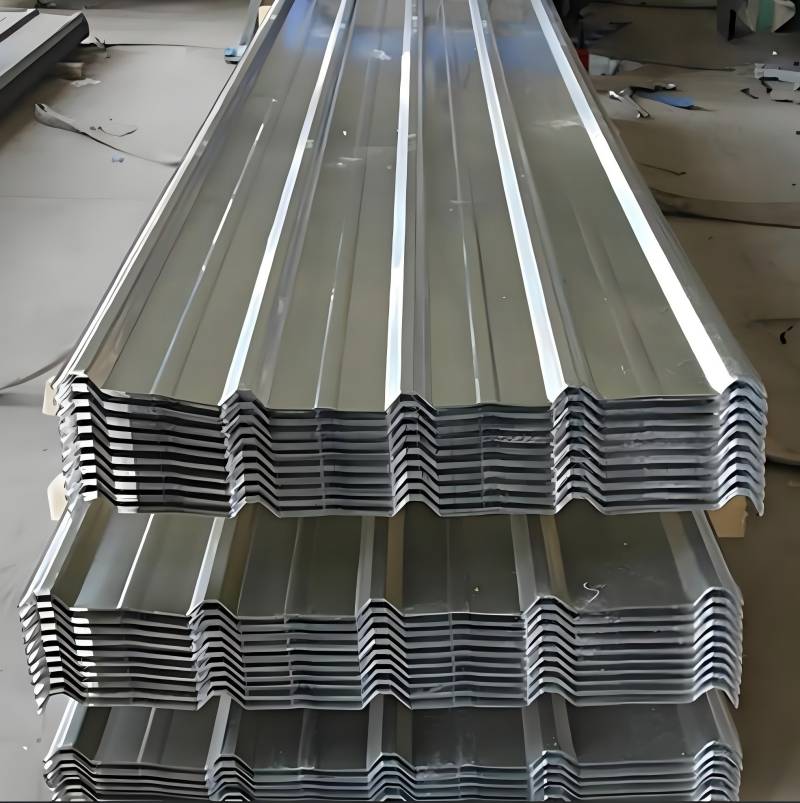

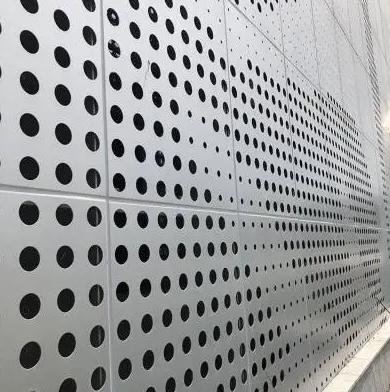

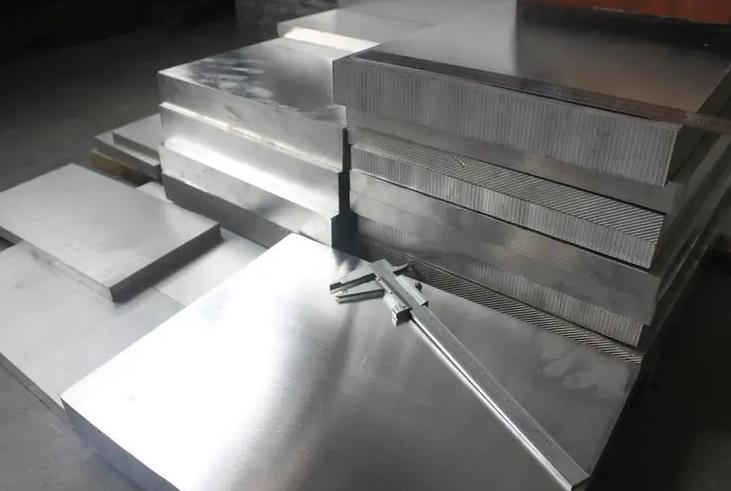

The curtain wall aluminum veneer base material adopts 1100H24, 3003H24, 5005H24, and other special single-layer aluminum plates for the curtain wall. As a kind of aluminum curtain wall, aluminum veneer curtain wall has advantages in the use of high-rise buildings due to its light texture and good strength. Because high-rise buildings are always subjected to various loads, especially the wind pressure, mosaic It is easy to fall off, and the curtain wall material with low hardness will be deformed due to the large wind pressure. High-rise buildings are large users of curtain walls, and aluminum veneer curtain walls are widely used based on their unique advantages. As a high-quality material, aluminum veneer has received more and more attention from all walks of life in building curtain walls and building decoration. Especially as a high-quality curtain wall material, it has received more and more attention from all walks of life.

Steps of Installing Aluminum Veneer

(1) The aluminum veneer and accessories are transported to each construction node with vertical transportation equipment such as elevators.

(2) Clean the inner side of the aluminum veneer and the surface of the column frame with detergent.

(3) The whole aluminum veneer is connected to the keel through the surrounding aluminum corners (hanging ears) and fixed on the keel.

(4) Fixing method: If it is a seamlessly spliced aluminum veneer inside, you can use an electric drill to turn the hole at the corresponding position on the keel, and then use a flat head (countersunk) aluminum rivet to rive it; The end screw is directly drilled into the keel through the connecting hole of the aluminum angle code to fix the aluminum plate, but pay attention to controlling the tightness of the drill bit to adjust the aluminum plate.

(5) Before the aluminum veneer enters the field, make a trial assembly. First fix the aluminum veneer on the keel slightly, pay attention to the control of the installation accuracy, and adjust the plate before tightening.

(6) When installing the aluminum veneer, install it on the wall in sequence according to the number of the aluminum veneer.

(7) The installation of aluminum veneer starts from the front, large area, and corner, and the principle of installation from top to bottom.

(8) The connection between the aluminum veneer and the keel must meet the requirements of the drawings, it must be firm and reliable, and bolts must be installed.

(9) The corners of the curtain wall and the surrounding walls, the connection structure of the upper and lower seals, and the treatment of the deformation joints shall meet the design requirements.

(10) Curtain wall joint structure and closing treatment

Wall panel joints: Usually, the joints of the joints are prone to uneven top and bottom or unequal panels. Therefore, one side panel should be installed first, aligned with the line, and the horizontal and vertical control lines should be used to determine the installation position of the other side panel. After both sides of the board meet the requirements, then pull out the rivets in turn, and install the pressure plate to fix it.

The lower end of the wall is closed: special water retaining plate is made according to the actual size, the lower end is sealed, and the gap between the plate and the wall is covered at the same time to prevent rainwater from seeping into the room.

(11) When installing, pay attention to the gap between the panels and the height requirements of the panel interface.

(12) After the aluminum veneer is installed, cover and protect the parts that are prone to contamination with plastic film or other materials.

Aluminum Veneer Installation Precautions

- When transporting the aluminum veneer, handle it with care, and do not hit it hard, otherwise, the edges and corners of the aluminum plate and its surface will be damaged, which will affect the installation and construction and waste money.

- During the installation process, pay attention to protecting the board surface, and the board surface should not touch the ground to avoid scratching the decorative surface.

- The variety, quality, color, shape, and line of the aluminum veneer should meet the design requirements and have the corresponding product qualification certificate.

- If the skeleton of the curtain wall is made of steel keel, its specification and shape should meet the design requirements and should be dusted and anti-rust treatment.

- In the installation of aluminum veneer, when there is no design requirement, such as core-pulling aluminum rivets, a rubber ring must be placed in the middle, and the distance between the core-pulling rivets should be controlled by 100mm-150mm.

- After the aluminum veneer is installed, remember to tear off the protective film after 3 days, it will be difficult to tear off after a long time, and it will also affect its appearance after tearing the film.

Conclusion

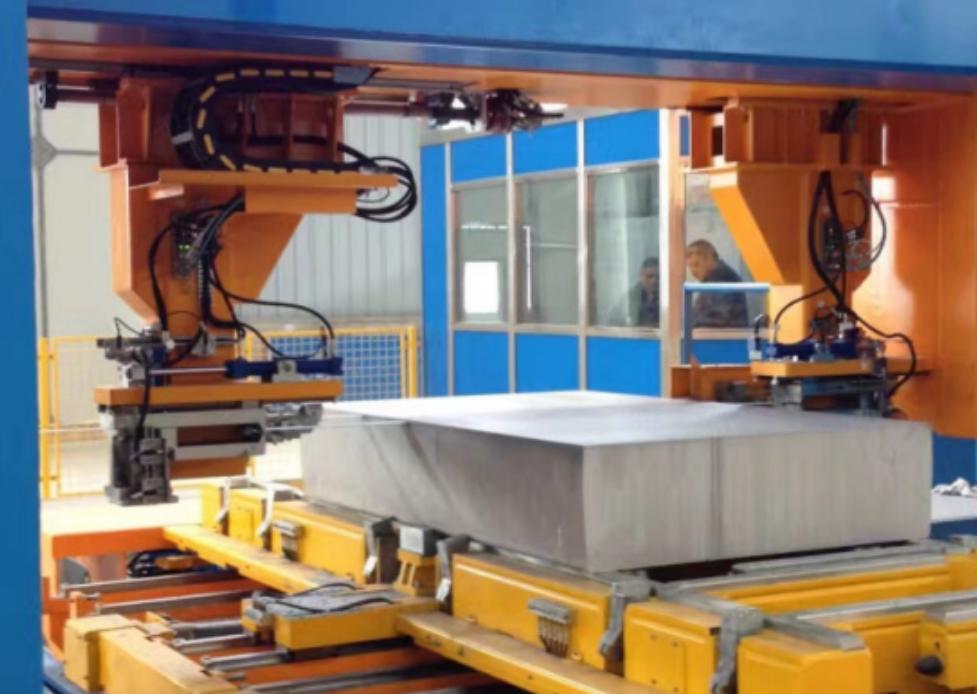

CHAL is a supplier with a focus on aluminum plates. You may find a range of high-quality aluminum processing materials at CHAL, including aluminum plates, aluminum sheets, aluminum profiles, and aluminum tubes. Every year, we supply high-quality aluminum products to hundreds of businesses all around the world, and the material dependability and safety are what allow us to gain market share.