Trailers serve a multitude of purposes, from hauling cargo to providing mobile living spaces. The skin of your trailer plays a crucial role in its durability, functionality, and aesthetics. Aluminum sheets have become a popular choice due to their lightweight nature, corrosion resistance, and versatility. However, selecting the right aluminum sheet involves considering several factors, including alloy, thickness, finish, and type, etc. Understanding the specific needs of your trailer is the first step in selecting the right aluminum sheet. Whether you’re building a cargo trailer, a food truck, or an RV, the demands on the material will vary. This article will guide you through the process, ensuring you make an informed decision for your trailer project.

Choosing the Right Aluminum Alloys for Trailers

Aluminum alloys are a combination of aluminum and other elements, such as magnesium, manganese, or silicon, to enhance specific properties. For trailer applications, strength and corrosion resistance are paramount. The most commonly used aluminum alloys for trailers are:

| Alloy | Advantages | Ideal Applications |

| 6061-T6 | High strength-to-weight ratio. Excellent weldability. Good corrosion resistance. Versatile. | Structural components (frames, supports). Sidewalls and roofs. General-purpose trailers. |

| 5052-H32 | Excellent corrosion resistance (especially in marine environments). Good formability. Good weldability. | Marine trailer skins. Trailers exposed to harsh weather. Applications requiring good formability. |

| 3003-H14 | Excellent formability. Moderate strength. Cost-effective. | Interior panels. Applications requiring deep drawing or bending. Cosmetic panaling. |

When selecting an aluminum alloy for your trailer, consider factors such as exposure to elements, required strength, and ease of fabrication. For general trailer siding, 3003 or 5052 aluminum is often the best choice, while 6061 is better suited for high-strength structural applications.

Choosing the Right Aluminum Sheet Thickness for Your Trailer

Aluminum sheet thickness is measured in gauges or millimeters. The thickness of the aluminum sheet directly impacts the trailer’s durability, weight, and cost. Below is a comparison of common thickness options:

| Thickness (Inches) | Advantages | Ideal Applications | Load Capacity Considerations |

| 0.025″ – 0.040″ (Thin) | Lightweight. Cost-effective. Flexible and easy to work with. | Interior panels. Cosmetic skins. Applications where weight reduction is crucial. cosmetic or light duty covering. | Low load capacity, prone to damage |

| 0.050″ – 0.080″ (Medium) | Good balance of strength and weight. Provides adequate protection. Versatile for various applications. | Sidewalls and roofs of cargo and utility trailers. General-purpose trailers. most common sizes for general purpose trailers. | Moderate load capacity, common choice. |

| 0.090″ and above (Thick) | Maximum strength and impact resistance. Enhanced structural integrity. Durable for heavy-duty applications. | Heavy-duty trailers. Off-road trailers. Flooring for heavy equipment trailers. trailers where impact is expected | High load capacity, maximum durability. |

Selecting the appropriate thickness depends on the trailer’s intended use. For example, enclosed cargo trailers typically use 0.040-inch aluminum sheets, while utility trailers may require 0.063-inch or thicker for added durability.

Choosing the Right Aluminum Sheets Color and Finishes for Trailers

Aluminum sheets are available in various colors and finishes, allowing for customization and enhanced durability. Common options include:

| Finish Type | Pros | Cons | Ideal Applications |

| Painted (Powder Coated, Baked Enamel) | Durable, wide color range, weather-resistant | Can chip or scratch, potential for fading over time | Exterior panels, custom designs, trailers needing specific colors |

| Anodized | Enhanced corrosion resistance, metallic sheen, various color options | Limited color range compared to paint, can be more expensive | Exterior trim, decorative panels, trailers emphasizing a modern look |

| Mill Finish | Cost-effective | Requires additional protection, prone to oxidation | Interior panels, applications where cost is primary, projects where painting will be done later |

| Diamond Plate | Slip-resistant, durable, hides scratches and dents | Adds weight, can be difficult to clean | Trailer floors, ramps, exterior trim for utility trailers |

Choosing the right finish depends on both functional and aesthetic preferences. Anodized or painted aluminum is ideal for improving the trailer’s look while protecting against corrosion, whereas diamond plate aluminum adds a rugged, non-slip surface.

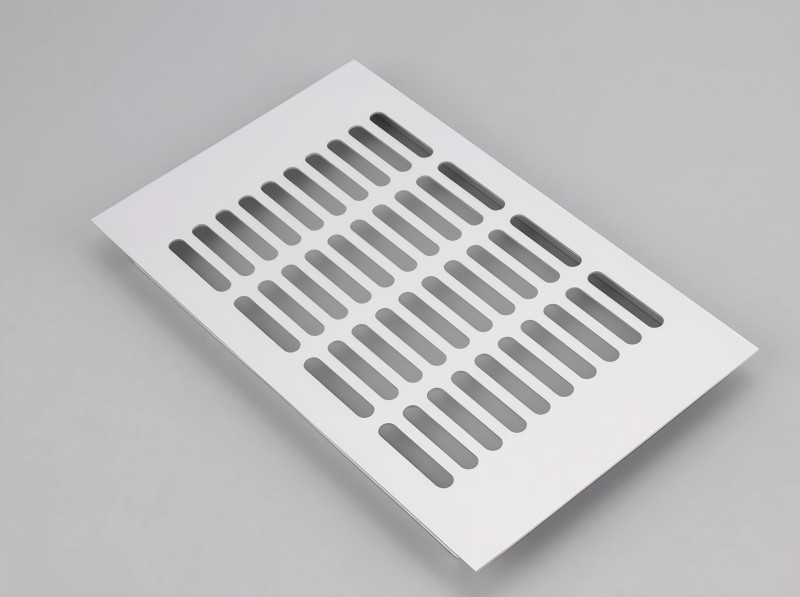

Choosing the Right Type of Aluminum Sheets for Trailers

Beyond alloys, thickness, and finishes, selecting the right type of aluminum sheet also depends on its intended application. The most common types include:

| Sheet Type | Features | Ideal Applications |

| Smooth Sheets | Flat, uniform surface, easy to clean | Exterior panels, interior walls, applications needing a clean aesthetic |

| Diamond Plate Sheets | Raised diamond pattern, slip-resistant, hides damage | Trailer floors, ramps, toolboxes, areas requiring traction |

| Embossed Sheets | Raised patterns, adds texture and rigidity | Interior panels, decorative trim, areas needing a unique look |

| Corrugated Sheets | Ribbed pattern, increased structural rigidity | Trailer roofs, exterior walls, applications needing extra strength |

Each type serves a specific purpose, so choosing the right one ensures optimal performance. For example, flat sheets work well for general trailer siding, while diamond plate sheets offer extra protection for high-impact areas like fenders and floors.

Choosing the Right Aluminum Sheet Size for Your Trailer

The size of the aluminum sheet you choose impacts material efficiency, installation ease, and cost. Aluminum sheets typically come in standard dimensions, such as:

- 4×8 feet – 4×8 aluminum sheet is the most common size, ideal for general trailer paneling and siding.

- 4×10 feet – Provides extended coverage for larger trailer sections, reducing the need for multiple sheets.

- 5×10 feet – Suitable for wider trailers, minimizing seams and improving structural integrity.

- Custom sizes – Some suppliers offer custom cuts to fit specific trailer designs.

When selecting the right size, consider the dimensions of your trailer to reduce waste and simplify installation. Larger sheets can help minimize seams, leading to a smoother finish and improved durability.

Selecting the right aluminum sheet for your trailer requires careful consideration of various factors, including alloy type, thickness, size, finish, and sheet type. The best choice depends on your trailer’s intended use, environmental exposure, and desired aesthetics. If you have some aluminum sheet needs, feel free to contact CHAL.