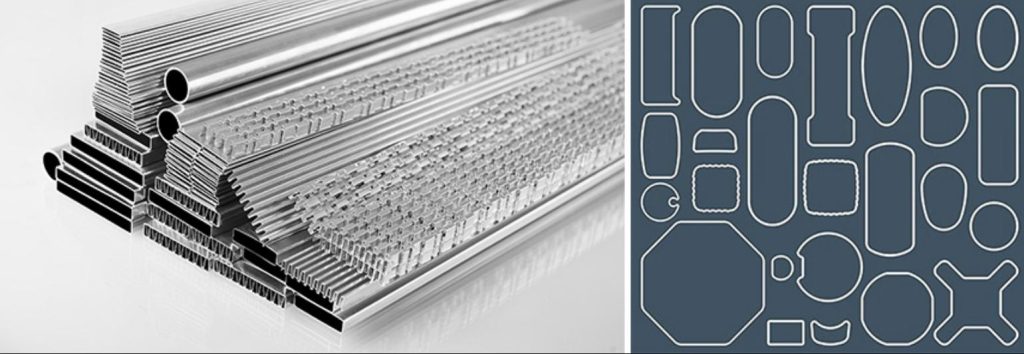

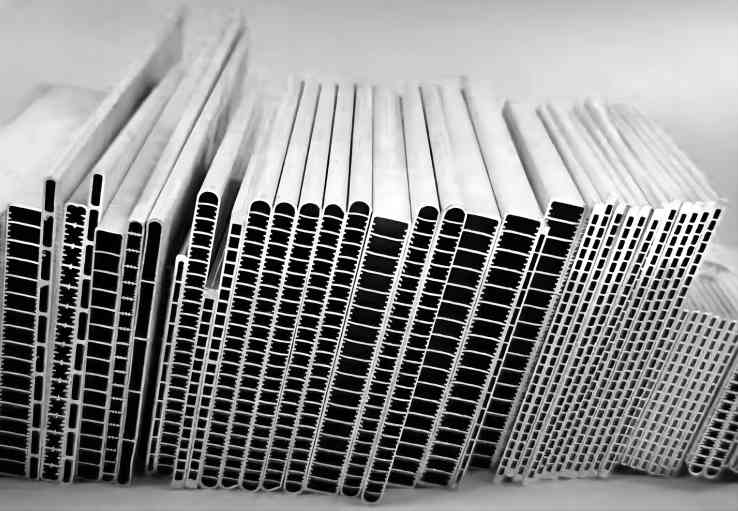

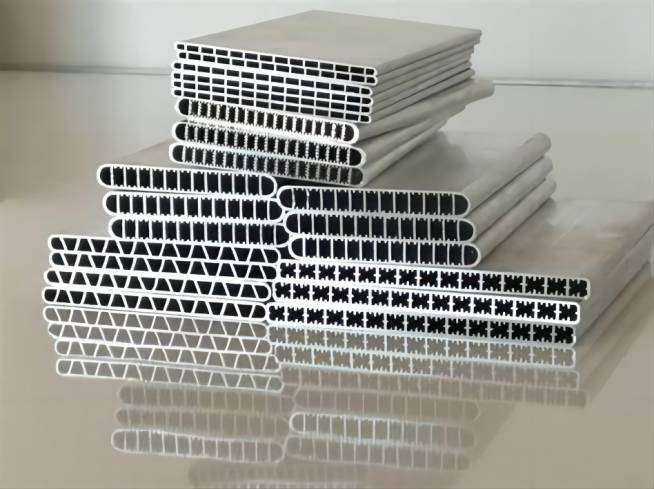

An aluminum tube is a kind of non-ferrous metal tube, which refers to a metal tubular material formed by extrusion processing of pure aluminum or aluminum alloy. Aluminum tube is also called aluminum pipe. Common aluminum tubes include aluminum round tubes, aluminum rectangular tubes, and aluminum square tubes. Aluminum tubes have good corrosion resistance and light weight. Therefore, it is often used as a heat pipe. Although the aluminum tube itself has good corrosion resistance, it can still rust sometimes. Why is there such a situation?

Why do Aluminum Tubes Still Rust?

As the metal surface is in contact with the environment, over time, the surface metal is oxidized, losing the mechanical properties and appearance of the original metal form. Aluminum is a material with strong corrosion resistance, but it will form an aluminum oxide on the surface of aluminum when exposed to oxygen, and its corrosion resistance and gluten resistance will gradually disappear for a long time. Alumina is very thin, its thickness is only one ten-thousandth of a millimeter, but it is very hard and very wear-resistant. It is close to the surface of the aluminum material, so that the aluminum material inside cannot contact the outside air, and prevents the aluminum material from continuing to rust. As a processed product of aluminum material, the aluminum tube naturally has the same characteristics.

In addition, aluminum is very sensitive to acidic substances. When it encounters acidity, it will destroy the surface composition layer of aluminum.

The Solution to Aluminum Tube Rust

Now we all know that aluminum tubes have good corrosion resistance, but if there is rust on the surface of aluminum tubes, how should we solve this problem?

Pickling and Rust Removal

When using pickling to remove the rust of aluminum pipes, you must first remove the oil stains on the surface of the rusted aluminum pipes. If the oil stains are not removed, the rust will not be removed. However, this method has low rust removal efficiency and a long time. The pickling and rust removal operation is simple, the friction loss of the substrate is small, and the surface of the profile after rust removal is in a semi-bright state, which can be directly colored or surface oxidized.

Lye Descaling

Put the rusty aluminum into an alkaline chemical solution. First of all, we have to decide which alkaline solution to use according to the type of material and the surface condition of the aluminum material. Secondly, if there is grease on the surface of the aluminum, the grease must be cleaned first. If the oil stains are not removed, the quality of the surface treatment may be reduced. The lye descaling is the same as pickling descaling, it takes a long time to wait for the chemical reaction to occur, and the post-treatment time is also relatively long.

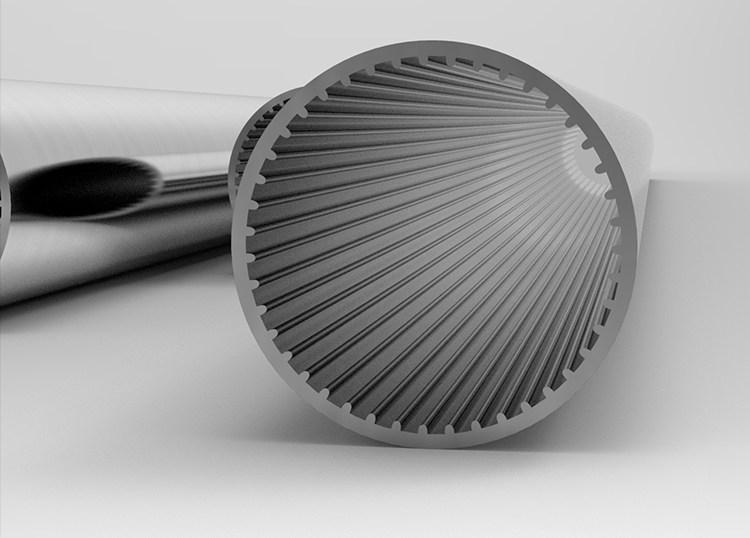

Oxidation Treatment of Aluminum Tube – Anodized Aluminum Tube

The best solution to the problem of aluminum tube rusting is to anodize the aluminum tube.

The principle of aluminum anodization is essentially the principle of water electrolysis. When the current passes, the following reactions will occur:

On the cathode, H2 is released according to the following reaction:

2H + + 2e → H2

On the anode:

4OH-4e → 2H2O + O2

The precipitated oxygen is not only molecular oxygen (O2) but also atomic oxygen (O) and ionic oxygen (O-2), which are usually represented by molecular oxygen in the reaction.

The aluminum as the anode is oxidized by the oxygen precipitated on it, forming an anhydrous Al2O3 film:

2Al + 3[O] = Al2O3 + 1675.7KJ

It should be pointed out that not all of the generated oxygen interacts with aluminum, and part of it is precipitated in gaseous form.

Simply put, the use of anodizing process to solve the problem of aluminum tube rust is: This method uses aluminum tube or aluminum alloy tube as the anode, which is put into the electrolyte for energization treatment, and the aluminum is placed on the anode The process of forming. The aluminum oxide film formed on the surface by electrolysis is called anodizing treatment of aluminum and aluminum alloy tubes.

The application of direct current sulfuric acid anodizing is the most common because it has anodizing treatment suitable for aluminum and most aluminum alloys; the film layer is thicker, harder and wear-resistant, and better corrosion resistance can be obtained after sealing; The film is colorless and transparent, has strong adsorption capacity and is easy to color; the processing voltage is low, and the power consumption is low; the processing process does not need to change the voltage cycle, which is conducive to continuous production and practical operation automation; sulfuric acid is less harmful to humans than chromic acid, and has a wide supply, Low price, and other advantages.

Of course, there are processed anodized aluminum tubes on the market now. Compared with ordinary aluminum tubes, anodized aluminum tubes are more resistant to corrosion. At the same time, it has higher hardness and better wear resistance. However, due to the different manufacturing methods of various manufacturers and the different aluminum materials used, the quality of the anodized aluminum tubes produced is also uneven. Therefore, choosing a high-quality aluminum tube supplier is particularly important.

If you need high-quality aluminum tubes or anodized aluminum tubes, you can contact us. We are CHAL Aluminium Corporation. We are a professional aluminum tube manufacturer, and our products include but are not limited to anodized aluminum tubes.