Aluminium, in its elemental form, is a versatile metal known for its lightness and strength. However, when ground into fine particles and suspended in a liquid medium, it transforms into a highly functional pigment known as aluminium paste. This article explores the science, applications, and benefits of water-based aluminium paste, particularly in the context of paint formulations.

Understanding Water-Based Aluminium Paste

1. Composition and Properties of Aluminium Paste

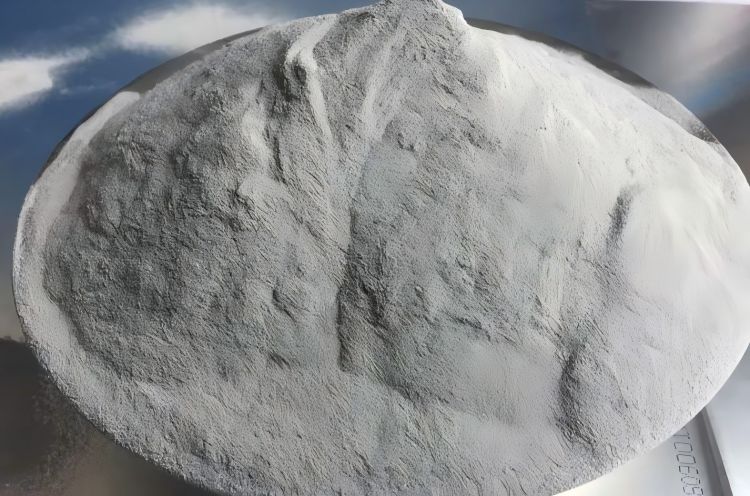

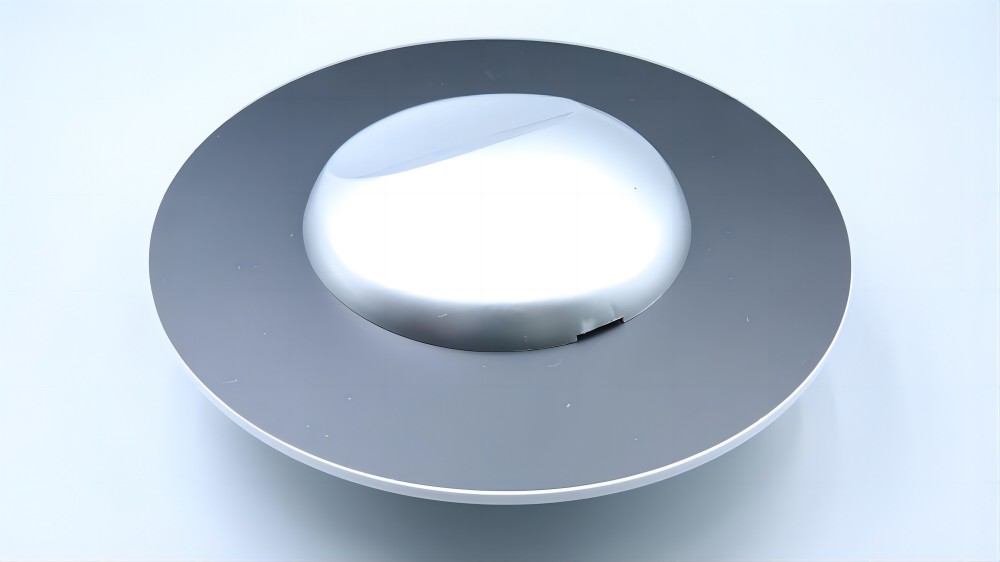

Water-based aluminium paste is a specialized form of aluminium pigment where finely ground aluminium particles are dispersed in a water medium. The aluminium particles used in these pastes typically range from a few microns to tens of microns in size. This size range is crucial, as it influences the paste’s performance in various applications.

The aluminium particles in the paste are coated with a protective layer to prevent oxidation. This layer ensures that the aluminium remains stable and maintains its desired properties over time. The choice of coating and the particle size can be adjusted based on specific application requirements, making water-based aluminium paste a highly versatile product.

2. How Aluminium Paste is Manufactured

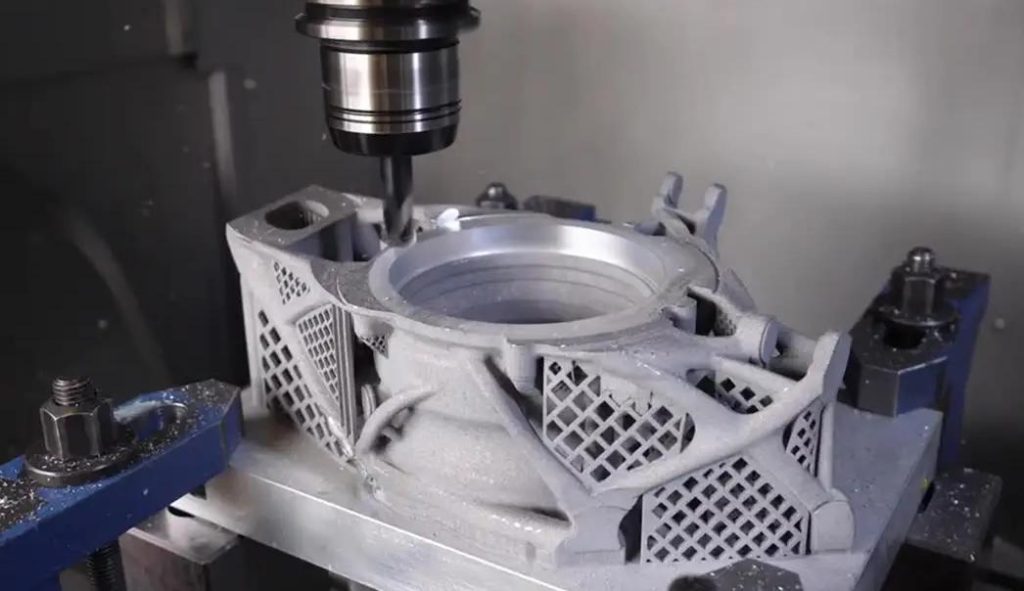

The production of water-based aluminium paste involves a detailed milling process. Aluminium sheets are first cut into small pieces and then subjected to milling in the presence of a liquid medium. For water-based aluminium paste, water serves as the medium, along with a dispersing agent to stabilize the suspension and prevent the particles from agglomerating.

The milling process is essential for achieving the desired particle size and distribution. The use of water as a medium not only aids in the milling process but also ensures that the final product is free from harmful solvents, making it more environmentally friendly compared to solvent-based alternatives.

3. Advantages of Water-Based Formulations over Solvent-Based Alternatives

- Environmental Benefits: Water-based aluminium paste does not release volatile organic compounds (VOCs) during application. VOCs are harmful to both human health and the environment, making water-based formulations a more sustainable choice.

- Safety Aspects: The absence of flammable solvents in water-based aluminium paste makes it safer to handle and use. This safety advantage is particularly important in industrial settings where flammability can be a significant risk.

- Performance Benefits: Water-based aluminium paste often exhibits better flow properties compared to solvent-based pastes. This can result in a smoother finish and more consistent application, enhancing the overall quality of the final product.

Aluminium Paste as a Pigment

1. The Role of Aluminium Paste in Paint Formulation

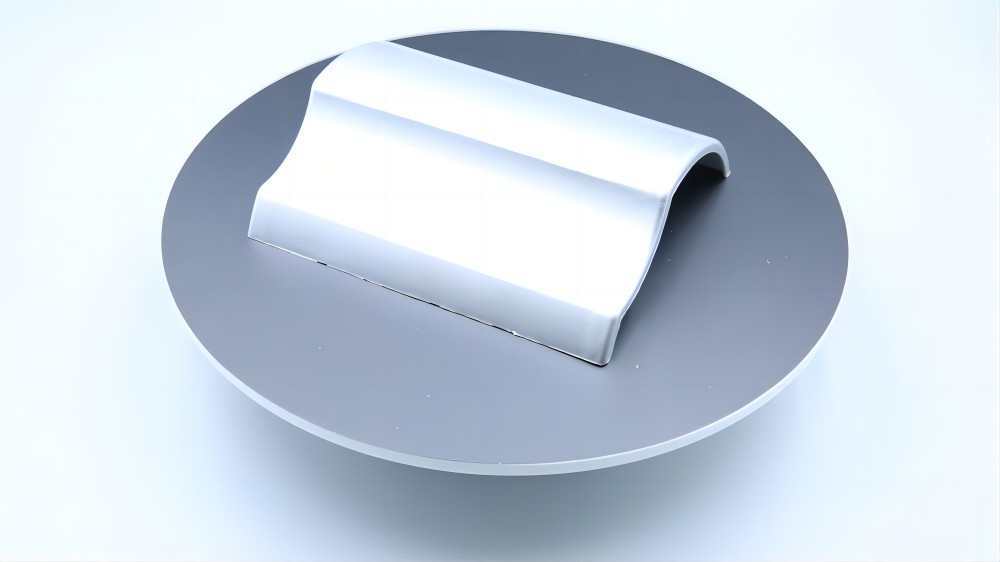

In the realm of paint formulation, aluminium paste plays a crucial role as a metallic pigment. Its primary function is to impart metallic luster and reflective properties to the paint. This effect is highly valued in applications where a high level of gloss and a distinctive metallic appearance are desired.

Aluminium paste for paint is prized for its ability to enhance the visual appeal of coatings. By varying the concentration and formulation of the paste, manufacturers can achieve a wide range of metallic effects, from subtle sheens to vibrant, reflective finishes.

2. Comparison with Other Metallic Pigments

When compared to other metallic pigments like bronze or copper powders, aluminium paste offers several advantages.

- Superior Corrosion Resistance: Aluminium paste provides better corrosion resistance than many other metallic pigments. This makes it particularly valuable in coatings for environments that are exposed to harsh conditions, such as marine or industrial applications.

- Durability: The durability of aluminium paste means it maintains its appearance and performance over time, reducing the need for frequent reapplication or maintenance.

- Efficiency: The high reflective index of aluminium paste means that less pigment is required to achieve the desired opacity and metallic effect. This efficiency can result in cost savings and reduced material usage.

3. The Effect of Aluminium Paste on Paint Properties

- Opacity and Hiding Power: Aluminium paste significantly enhances the opacity of the paint, allowing it to cover surfaces more effectively with fewer coats. This can lead to more efficient use of paint and better overall coverage.

- Metallic Luster and Color Effects: The metallic luster of aluminium paste can be adjusted by varying the particle size and shape. This flexibility allows for a wide range of color and finish effects, from smooth and subtle to bold and striking.

- Corrosion Resistance and Durability: Aluminium paste adds an additional layer of protection against corrosion. This is especially beneficial in marine and industrial coatings where resistance to environmental factors is crucial.

Applications of Aluminium Paste in Paints

- Architectural Coatings: Water-based aluminium paste is widely used in architectural coatings for both exterior and interior applications. Its decorative effects and ability to withstand environmental conditions make it a popular choice for enhancing the appearance of buildings. Whether used in residential or commercial projects, water-based aluminium paste contributes to the aesthetic appeal and durability of architectural coatings.

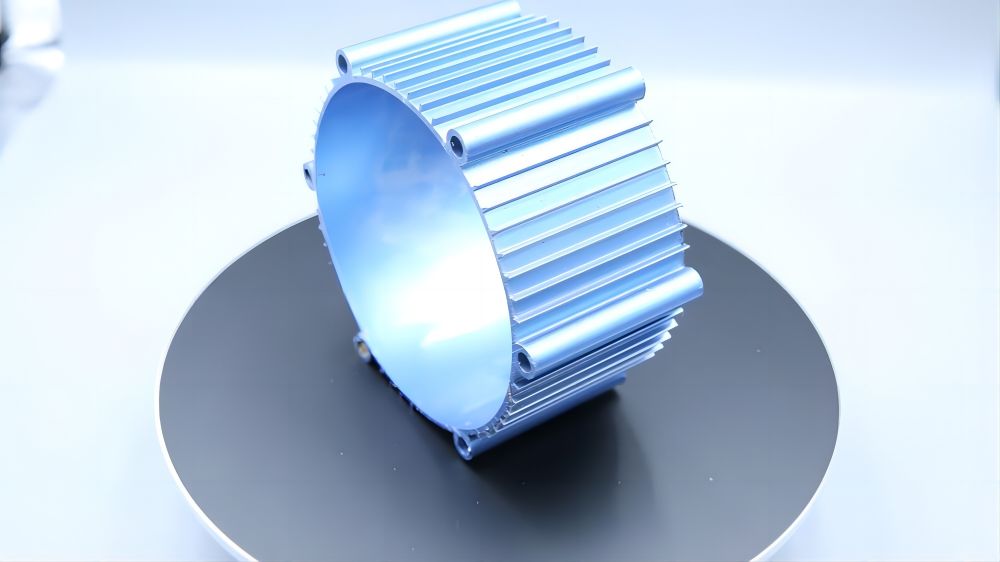

- Industrial Coatings: In industrial settings, aluminium paste is utilized for protective coatings on metal surfaces. Its high corrosion resistance makes it ideal for applications in marine and aerospace industries, where protection against the elements is essential. The durability and performance of aluminium paste ensure that industrial coatings remain effective over time, even in harsh environments.

- Automotive Coatings: Automotive coatings often incorporate aluminium paste, particularly in primers and basecoats. The paste provides a smooth, metallic finish that enhances the aesthetic appeal of vehicles. Additionally, aluminium paste contributes to the durability and resistance of automotive coatings, ensuring that they maintain their appearance and protective properties.

- Specialized Uses: Beyond traditional paint applications, aluminium paste finds use in various specialized areas. It is used in inks and printing applications to achieve metallic effects, as well as in artistic and craft paints where a distinctive metallic sheen is desired. Its versatility makes it a valuable ingredient in a wide range of formulations.

Choosing the Right Aluminium Paste for Paint Formulations

1. Factors to Consider When Selecting Aluminium Paste

- Particle Size and Shape: The size and shape of aluminium particles influence the finish and effect of the paint. Smaller particles produce a finer finish, while larger particles create a more pronounced metallic effect.

- Brightness and Luster: The brightness and lustre of aluminium paste can vary based on the quality of the aluminium and the production process. Selecting a paste with the desired level of brightness and lustre is essential for achieving the intended visual effect.

- Compatibility with Other Paint Ingredients: Ensuring that the aluminium paste is compatible with other ingredients in the paint formulation is crucial. Incompatibility can lead to adverse interactions, affecting the performance and quality of the final product.

2. Tips for Optimizing the Performance of Aluminium Paste in Paints

- Dispersion Techniques: Proper dispersion techniques are essential to ensure a uniform distribution of aluminium paste in the paint. Effective dispersion improves the consistency and performance of the paint.

- Stabilizers and Surfactants: The addition of stabilizers and surfactants can enhance the stability and compatibility of aluminium paste in water-based formulations. These additives help prevent issues such as settling or separation of the paste.

- Testing and Quality Control: Regular testing and quality control measures are necessary to ensure that the aluminium paste meets performance standards. This helps maintain the quality and reliability of the paint.

Conclusion

Water-based aluminium paste represents a significant advancement in the use of aluminium pigment in paint formulations. Its eco-friendly nature, combined with its superior performance characteristics, makes it an attractive choice for a wide range of applications, from architectural to industrial coatings. As the paint industry continues to evolve, water-based aluminium paste stands poised to play a pivotal role in driving innovation and sustainability.

If you are looking for high-quality water-based aluminium paste for your paint formulations, please contact CHAL to get a competitive price.