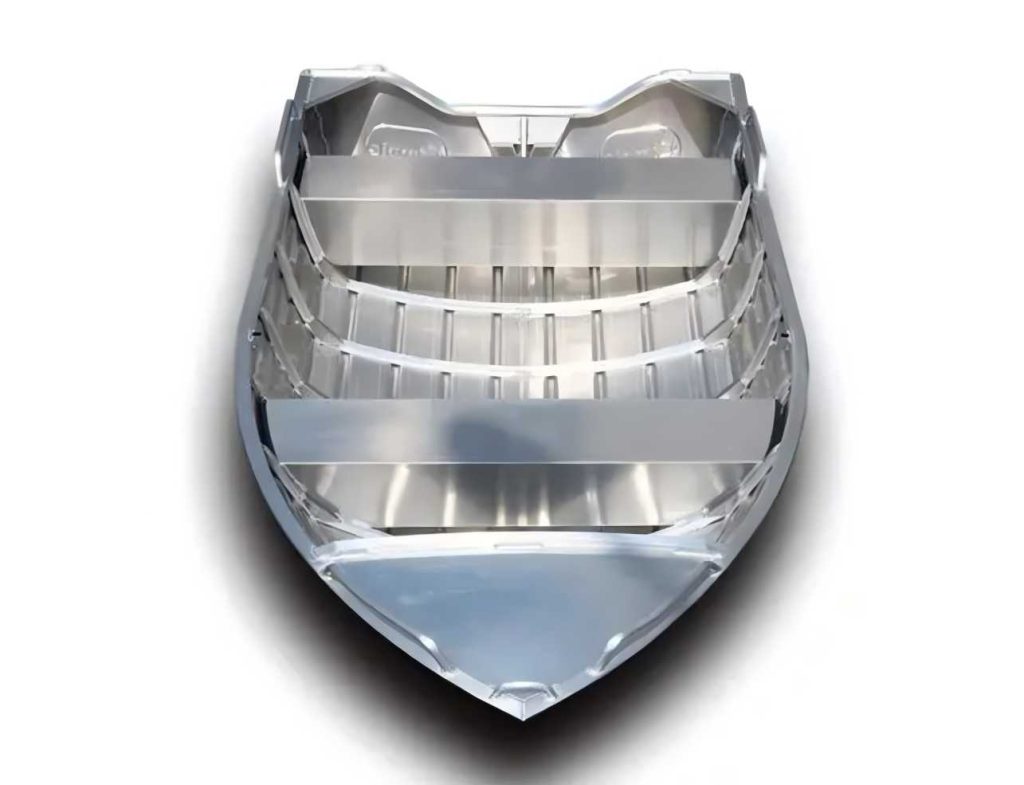

Aluminum has become a material of choice in the boat building industry due to its favorable properties such as lightweight, high strength, and excellent resistance to corrosion. However, not all aluminum alloys are created equal. The choice of aluminum alloy significantly influences the longevity and performance of a boat structure. This article delves into the types of aluminum alloys commonly used in boat building, factors affecting boat structure longevity, process of selecting the right alloy, and recommend you a reliable source for marine aluminum.

Types of Aluminum Alloys in Boat Building

Aluminum alloys are created by adding elements like copper, magnesium, silicon, and zinc to pure aluminum, enhancing its properties for specific applications. In boat building, several alloy types are commonly employed:

- 5000 Series Alloys: Widely used in marine environments due to their excellent corrosion resistance. They offer a good balance of strength and weldability.

- 6000 Series Alloys: Known for their high strength-to-weight ratio, making them suitable for demanding applications like hulls and frames. However, they might require additional protection against corrosion.

Here are some common marine grade alloys for different boat applications:

| Types of Aluminum Alloys | Applications in Boats | Representative Grades |

| Marine Grade Alloys | Structural frames, masts, components requiring high strength | 5052, 5083, 5086 |

| Structural Alloys | Structural frames, masts,components requiring high strength | 6061, 6063 |

| Specialized Alloys | Above-waterline applications, specialized parts | 2024, 7075 |

| Other Marine Alloys | Tanks, pressure vessels, extruded shapes and profiles | 5454, 6060 |

The choice of aluminum alloy plays a pivotal role in the performance and longevity of boat structures. Alloys such as 5083, 5086, 6061, and 5052 each offer distinct advantages, making them suitable for different parts of a boat. Proper understanding and selection of these alloys are essential for ensuring the durability and reliability of aluminum boats.

Factors Affecting Aluminum Boat Structure Longevity

The longevity of an aluminum boat structure is influenced by several factors, including:

1. Material Quality

- Alloy Type: The choice of aluminum alloy affects corrosion resistance and strength. Marine-grade alloys (like 5052, and 5083) offer better longevity in harsh environments compared to other grades.

- Thickness: Thicker aluminum provides greater strength and resistance to impacts and wear.

2. Corrosion Resistance

- Environmental Conditions: Exposure to saltwater accelerates corrosion. Proper treatment and choice of alloy can mitigate these effects.

- Protective Coatings: Applying coatings or anodizing the aluminum can enhance resistance to corrosion.

3. Maintenance

- Regular Inspections: Frequent checks for signs of wear, corrosion, or damage can help address issues before they lead to more significant problems.

- Cleaning: Regularly cleaning the boat to remove salt, grime, and other contaminants can prevent corrosion.

4. Design and Construction

- Weld Quality: High-quality welding and proper techniques are crucial for ensuring structural integrity and preventing corrosion at weld joints.

- Design Considerations: Effective design that minimizes areas prone to water trapping or turbulence can reduce wear and damage.

5. Operational Factors

- Loading and Usage: Proper loading and avoiding excessive impact or strain can prevent structural damage.

- Docking Practices: Using fenders and avoiding abrasive contact with docks can prevent physical damage.

6. Environmental Protection

- Storage: Keeping the boat out of harsh weather conditions or using covers can reduce exposure to elements that cause degradation.

- Anti-Fouling: Applying anti-fouling paint can prevent marine growth, which can contribute to corrosion and structural issues.

7. Fabrication Techniques

- Quality of Components: Using high-quality rivets, fasteners, and other components can prevent issues related to wear and corrosion.

- Assembly Methods: Proper assembly and fitting of components ensure there are no gaps or misalignments that could lead to problems over time.

8. Temperature Changes

Aluminum expands and contracts with temperature changes. Proper allowances in design can prevent stress and structural issues.

By addressing these factors, you can significantly enhance the longevity and durability of an aluminum boat structure.

How to Select Aluminum Alloy for Boat Structure?

Choosing the right aluminum alloy for a boat structure involves careful consideration of various factors.

- Define Boat Usage and Environment: Determine the boat’s intended use (fishing, cruising, performance) and the operating environment (freshwater, saltwater, coastal, offshore).

- Identify Critical Components: Determine which parts of the boat require specific properties. For instance, the hull requires high corrosion resistance and strength, making 5083 and 5086 suitable choices. For components that need high stiffness and strength, like masts and booms, 6061 might be more appropriate.

- Evaluate Alloy Properties: Compare the properties of different aluminum alloys to match them with the boat’s requirements.

- Consider Cost: While high-performance alloys may offer better properties, they also come at a higher cost. Balancing budget constraints with the performance requirements is crucial. Sometimes, it might be more cost-effective to use a slightly lower-grade alloy with additional protective measures, such as coatings.

- Maintenance Requirements: The choice of alloy can also impact the maintenance needs of the boat. Alloys with higher corrosion resistance will require less frequent maintenance and repairs, reducing long-term costs and effort.

- Consult with Experts: Seek advice from experienced marine aluminum suppliers or engineers.

By carefully considering these factors, you can select the aluminum alloy that best suits your boat’s design and intended use, ensuring durability, performance, and longevity.

Get Marine Aluminum from CHAL

Choosing a reliable supplier for marine aluminum is as important as selecting the right alloy. CHAL is a reputable provider of high-quality aluminum alloys suitable for marine applications.

Quality Assurance

CHAL offers a range of marine-grade aluminum alloys, including 5083, 5086, 6061, and 5052. Their products are known for their superior quality, meeting stringent industry standards for performance and durability.

Expertise and Support

With extensive experience in the aluminum industry, CHAL provides expert guidance on alloy selection and application. Their customer support ensures that you get the right material for your specific needs, helping you maximize the longevity of your boat structures.

Conclusion

The selection of aluminum alloys significantly impacts the longevity of boat structures. Understanding the types of aluminum alloys, the factors affecting their performance, and how to select the appropriate alloy are crucial steps in building durable and reliable aluminum boats. By sourcing high-quality marine aluminum from trusted suppliers like CHAL, boat builders can ensure their structures withstand the test of time and harsh marine environments.