As early as a few years ago, the use of aluminum to build the structure of the car has become the highest car building standard in the industry. In that year, the BMW Brilliance 5 Series, which was the first in China to use an all-aluminum body, also received unanimous praise from the industry, while another luxury brand model of the same level adopted an all-aluminum structure after being made in China.

What are the benefits of an all-aluminum car structure? Why is it so sought after by end consumers? At the same time, corresponding to these advantages, what are the obvious shortcomings of the all-aluminum structure compared to the traditional steel body? On the whole, is the flaw outweighing the flaw or does the disadvantage outweigh the advantage?

All-aluminum structure makes the car lighter

First of all, the biggest advantage of aluminum alloy is that it is lighter in weight. Generally, the density of aluminum is 2.7/cm3, while the density of steel is 7.8g/cm3, and the weight of aluminum of the same volume is only about 1/3 of that of steel.

Facts have proved that the difference in weight between the body made of all-aluminum and the body made of steel plate is not small.

For example, the minimum weight of the BMW Brilliance 5 Series with an all-aluminum body mentioned at the beginning of our article is only 1705kg, while the minimum weight of a luxury brand model with a steel body is 1780kg. The latter is equivalent to the default state. Dora pulled an adult weighing 150 pounds.

The benefits that come with reducing vehicle weight are numerous.

First and foremost is the upgrade at the driving level. We all know that the lighter the weight of the car, the smaller the inertia, so whether the low-weight car starts, accelerates, brakes and turns, the inertia of the vehicle will be smaller, the responsiveness will be better, and the car will become It is easier to control, which is what we commonly call “easy to drive”.

There will also be better performance in terms of fuel consumption. According to an international research report, for every 100kg reduction in vehicle curb weight, the vehicle’s fuel consumption per 100 kilometers will be reduced by 0.3-0.6L.

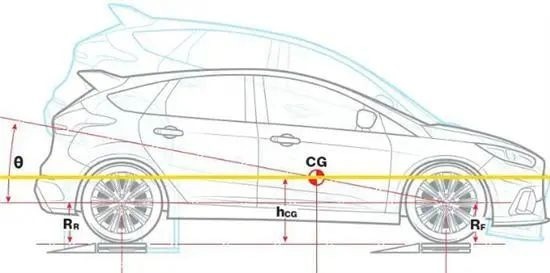

The use of aluminum alloy body can also reduce the height of the center of gravity of the body to achieve the purpose of optimizing the front and rear counterweight. Moreover, aluminum alloy suspension and control arms are also becoming more and more popular.

Compared with ordinary steel control arms, aluminum alloy can reduce the unsprung mass better, making the vehicle easier to handle and the vehicle more durable, easy to push. At the same time, reducing the unsprung mass can also reduce bumps and improve ride comfort.

Aluminium leads to better structural rigidity in cars

In our inherent impression, the strength of aluminum is not as good as steel. But in real life, through different processing techniques, the strength of aluminum alloy produced is also divided into three, six, nine, etc. By using different strength steel in different parts of the body, the all-aluminum body can also meet the safety requirements. strength.

In order to achieve a better strength of the body, many brands will add high-strength steel to the joints. Although the weight is slightly increased, the strength is higher than that of the all-aluminum body.

Better energy absorption

Although the strength of aluminum alloy material is not as good as that of high-strength steel, it gives aluminum alloy good ductility and can absorb energy through its deformation and collapse.

The strength of the car is important, but good energy-absorbing collapse can better release the energy generated by the collision, thereby protecting the occupants. Therefore, usually, the energy-absorbing box designed for the front bumper and rear bumper of the car will use low-strength aluminum alloy, so that the entire energy-absorbing box can be better collapsed.

Better corrosion resistance

With the increase in the service life of the vehicle, there will be different degrees of corrosion, but the aluminum plate does not have this concern, because it can react with the oxygen in the air to form an aluminum oxide film, thereby isolating the aluminum alloy from chemical reactions with external substances. . Therefore, aluminum alloy parts are more resistant to corrosion than steel plates.

Disadvantages of all-aluminum car structure

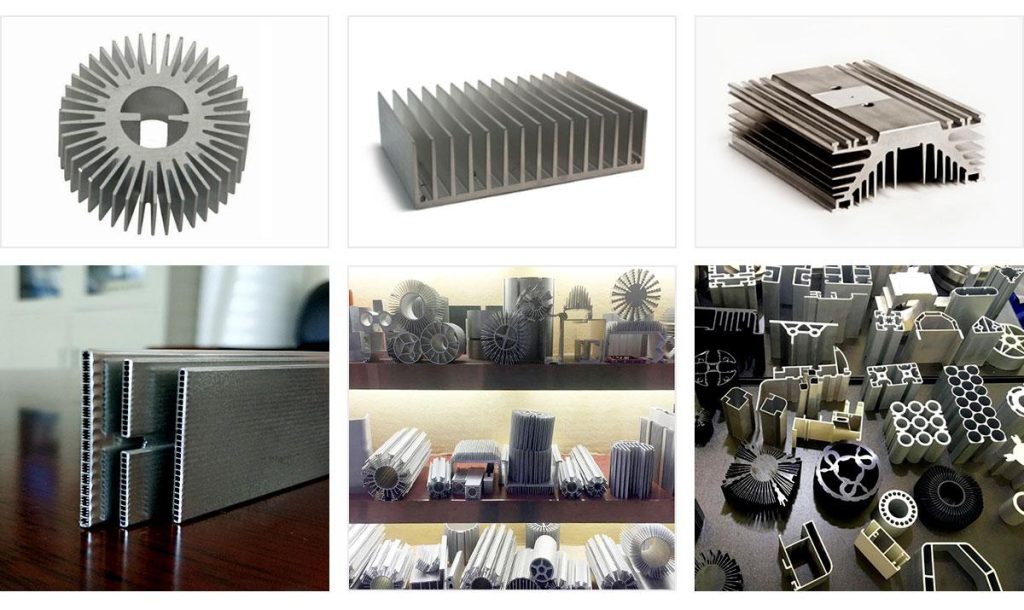

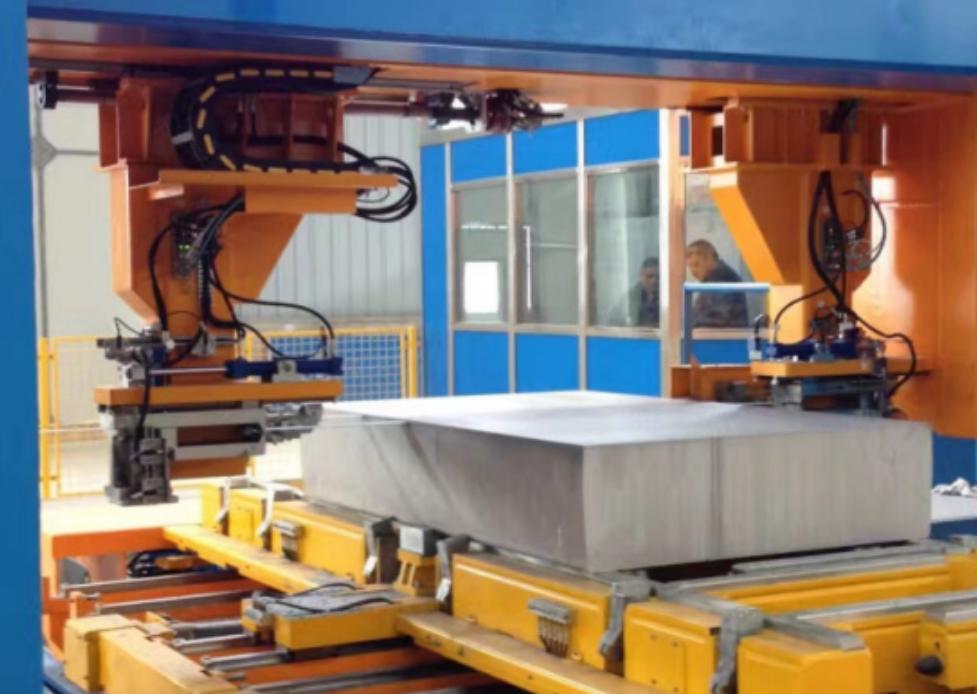

After talking about the advantages of an aluminum body, let’s talk about the disadvantages. That is, the processing of the aluminum body is difficult and the cost is high. The welding process of aluminum and steel and aluminum is very technically difficult and expensive. The welding process is an important factor affecting whether a car factory can manufacture an “all-aluminum body”.

At present, the welding processes used in aluminum welding and steel-aluminum welding mainly include: riveting, screwing, resistance welding, laser welding, etc. The aluminum plate has poor toughness and is generally difficult to stamp. Compared with the steel plate, the stamping forming of the aluminum plate requires higher precision of equipment and process, which directly increases the manufacturing cost.

Therefore, in the family car within 200,000 yuan, aluminum alloy is not a mainstream material, mainly steel. For some cars with a price of more than 400,000 yuan, aluminum alloys are used now, so this explains why good cars are more inclined to use aluminum alloys.

Will aluminum body structures still become mainstream in China?

To put it simply, as far as the current Chinese consumer market is concerned, although all-aluminum car bodies are very popular, there are still fewer end consumers who choose and use all-aluminum car bodies. The reason is always the problem of spending power.

If you put aside spending power and only talk about the material itself, then the all-aluminum car structure must be a typical representative of the flaws, with obvious advantages. However, considering the issue of consumption power, many car companies have decisively abandoned the use of all-aluminum bodies to reduce costs and thus lower prices.

But I think that the all-aluminum body must be the future development trend. With the continuous innovation and improvement of the processing technology, the cost will be reduced, and as time goes on and the income increases, the all-aluminum body structure will be the future consumption. the main battlefield of the market.