Aluminum paste is a versatile material widely used in various industries for its unique properties and aesthetic appeal. This article delves into the types, characteristics, and applications of aluminum paste, focusing on leafing aluminum paste and non leafing aluminium paste. By understanding the differences between these types, we can appreciate their distinct advantages and appropriate uses in different contexts.

Understanding Aluminum Paste and Its Types

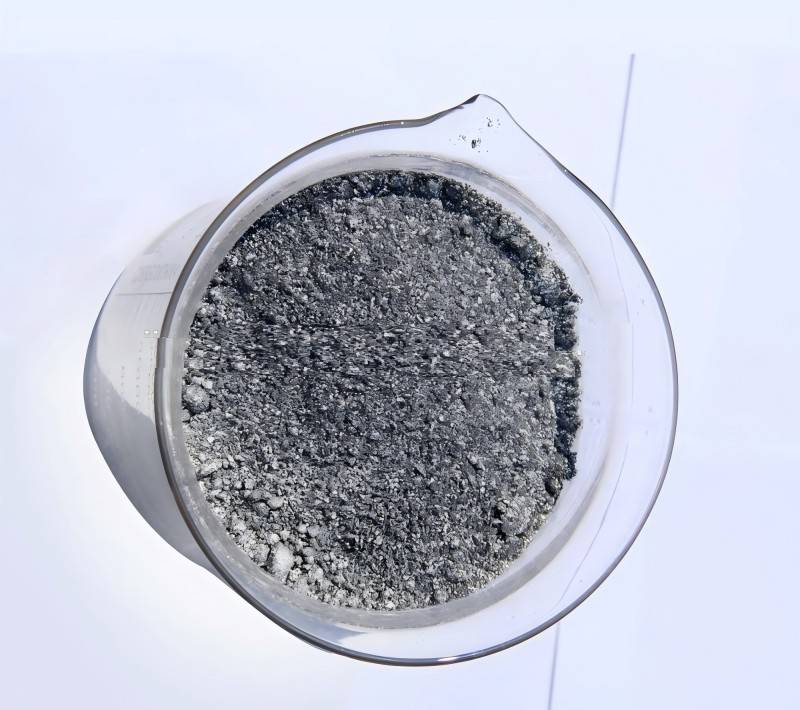

Aluminum paste is a compound consisting of aluminum flakes dispersed in a carrier solvent. It is renowned for its metallic finish, high reflectivity, and ability to enhance the aesthetic appeal of coatings and paints. Aluminum paste is categorized into two primary types based on its behavior within coatings: leafing aluminum paste and non-leafing aluminum paste. Each type has distinct properties and applications, making them suitable for different industrial needs.

The following summary table showcases the key differences between leafing and non-leafing aluminum paste, including their impact on the appearance and durability of coatings.

| Feature | Leafing Aluminum Paste | Non-Leafing Aluminum Paste |

| Description | Aluminum flakes float on the surface due to low surface tension. | Aluminum flakes are fully wetted, distributing evenly throughout the paint film. |

| Characteristics | 1. High reflectivity and chrome-like finish 2. Aluminum flakes on the surface 3. Offers excellent protection against corrosion | 1. Even distribution within the paint film 2. Strong adhesion to the substrate 3. Compatibility D5with various pigments |

| Applications | 1. Coatings for high-protection areas (e.g., roofs, tanks) 2. Automotive and furniture coatings for metallic shine | 1. Automotive, furniture, and electronic coatings 2. Multiple coatings (e.g., vehicle paints, coil coatings) |

How to Distinguish Between Leafing and Non Leafing Aluminium Paste

Characteristics of Leafing Aluminum Paste

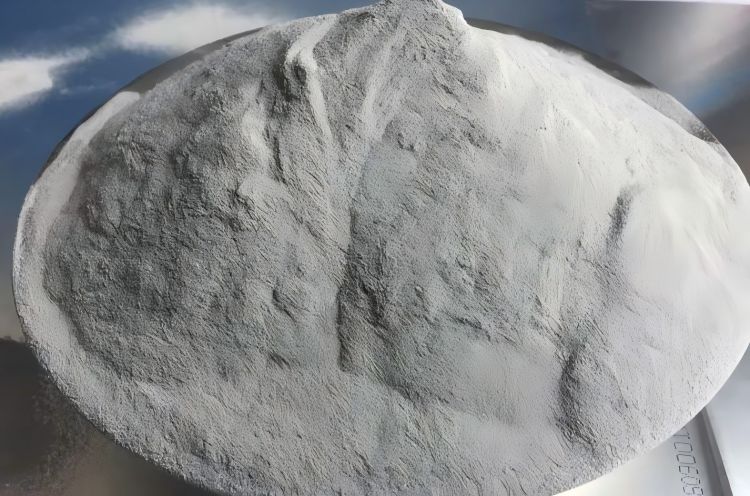

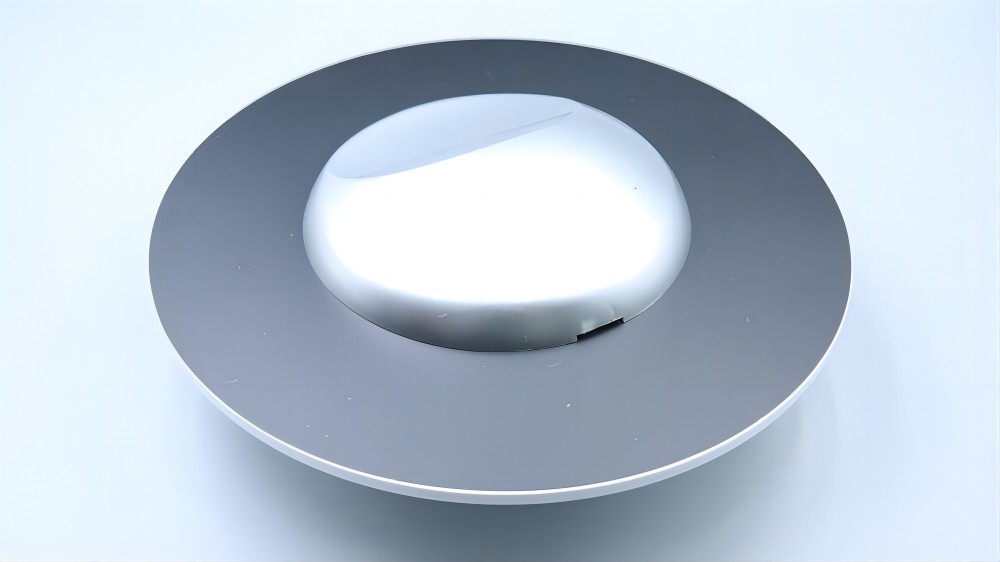

Leafing aluminum paste is particularly notable for its low surface tension, which allows it to float on the paint film surface. This property gives it a high gloss and metallic sheen, akin to a chrome finish. It is especially useful in applications where high reflectivity and corrosion resistance are needed.

- High Reflectivity and Chrome-Like Finish:

Leafing aluminum paste provides an unparalleled reflective surface, making it ideal for creating a metallic appearance similar to electroplating. This is particularly beneficial in the automotive industry for wheel coatings and interior paints, enhancing the vehicle’s aesthetic appeal.

- Applications in Corrosion Protection and Roofing:

The reflective properties of leafing aluminum paste also make it suitable for protective coatings on roofs and tanks. The aluminum flakes create a barrier that reflects UV radiation and heat, helping to protect the underlying materials from weathering and corrosion.

- Potential for Aluminum Flakes to Fall Off:

A notable drawback of leafing aluminum paste is the tendency for aluminum flakes to detach from the paint film. This can lead to challenges in recoating and maintaining the integrity of the finish over time.

Characteristics of Non Leafing Aluminium Paste

Non leafing aluminium paste offers a more integrated solution, with aluminum flakes evenly distributed throughout the paint film. This results in stronger adhesion and a more stable, durable coating.

- Complete Wetting by Paint:

Non leafing aluminium paste particles are completely wetted by the paint, ensuring even distribution and a tendency to sink into the film. This results in a more cohesive and stable finish.

- Strong Adhesion and Color Blending:

The uniform distribution of aluminum flakes in non leafing aluminium paste enhances the paint’s adhesion to the substrate. Additionally, this type of paste can be blended with various pigments, allowing for a wide range of decorative effects.

- Applications in Automotive, Furniture, and Electronics:

Non leafing aluminium paste is ideal for multiple coating applications, such as automotive paints, where durability and a consistent finish are critical. It is also used in furniture and electronic coatings, providing both aesthetic and protective benefits.

Methods for Distinguish Between Leafing and Non Leafing Aluminium Paste

The primary difference between floating and non-floating aluminum paste lies in their behavior within the coating. Floating aluminum paste tends to gather at the surface, creating a reflective layer, whereas non-floating aluminum paste disperses evenly throughout the film, providing stability and uniformity.

- Visual Observation Methods

- Floating aluminum paste: When mixed into a paint sample, the aluminum flakes will congregate at the surface, forming a distinct silver layer. This can be easily observed with the naked eye.

- Non-floating aluminum paste: In contrast, the flakes will be evenly distributed throughout the coating, without forming any visible layers. The overall color and gloss of the film indicate the uniform dispersion of the aluminum flakes.

- Microscopic Observation Techniques

- Floating aluminum paste: Under a microscope, the aluminum flakes will be seen at the top of the film, with visible gaps between the flakes.

- Non-floating aluminum paste: The flakes are spread evenly throughout the film, closely packed together, without any distinct layering.

- Coating Performance Tests

- Floating aluminum paste: Coatings made with floating aluminum paste may show lower adhesion, particularly when attempting to re-coat. The flakes may detach, affecting the integrity of the coating.

- Non-floating aluminum paste: Coatings made with non-floating aluminum paste demonstrate better adhesion and stability, ideal for applications requiring multiple coats.

Common Applications of Leafing Aluminum Paste

- Automotive Industry: In the automotive sector, leafing aluminum paste is used in interior paints and wheel coatings. Its reflective properties enhance the vehicle’s appearance, giving it a stylish and high-end look.

- Furniture Manufacturing: Leafing aluminum paste is also used in furniture coatings, providing wood and metal furniture with a unique metallic sheen. This enhances the aesthetic appeal and adds a touch of sophistication.

- Building Materials: In construction, leafing aluminum paste is applied to steel structures and roofing materials. Its reflective properties help protect buildings from UV radiation and heat, improving appearance and durability.

- Printing Industry: Leafing aluminum paste is suitable for gravure, flexographic, and screen printing. It imparts a consistent metallic gloss across various substrates, enhancing the visual quality of printed materials.

Advantages of Non Leafing Aluminium Paste Over Leafing Aluminum Paste

Non leafing aluminium paste offers several advantages over leafing aluminum paste, particularly in terms of adhesion, durability, and versatility.

- Better Adhesion: Non leafing aluminium paste provides stronger adhesion due to its even distribution within the paint film. This results in more durable and stable coatings, essential for applications requiring long-term performance.

- Recoatability: Non leafing aluminium paste is better suited for applications involving multiple layers of paint. Its uniform distribution ensures that new layers adhere well without affecting the underlying coating’s integrity.

- Decorative Effects: The ability to blend non leafing aluminium paste with various pigments allows for a wide range of decorative effects. This makes it ideal for creating realistic metallic surfaces and enhancing product aesthetics.

- Wide Application Range: Non leafing aluminium paste’s properties make it suitable for diverse applications, from automotive and furniture coatings to electronic devices and coil coatings. Its versatility and performance advantages make it a preferred choice for many industries.

Factors Affecting Adhesion of Aluminum Paste During Recoating

When recoating with aluminum paste, several factors can influence adhesion and the overall success of the application.

- Substrate Surface Treatment: The cleanliness and preparation of the substrate surface are crucial for ensuring strong adhesion. Contaminants like oil, dust, or residues from previous coatings can hinder the new layer’s ability to bond effectively.

- Coating Aging State: The condition of the existing coating also impacts adhesion. Aging coatings may require surface treatment, such as sanding or chemical preparation, to restore a suitable adhesion base.

- Recoat Interval: The time interval between coatings affects adhesion. Delayed recoating can lead to changes in the underlying layer’s properties, reducing the new layer’s bonding effectiveness.

- Environmental Conditions: Humidity and temperature during application can influence the curing process and adhesion. High humidity or improper temperature conditions can result in poor adhesion and coating defects.

- Application Technique: The methods and tools used during application affect the uniformity and adhesion of the coating. Inconsistent application can lead to defects like bubbles or pinholes, compromising the coating’s integrity.

- Material Compatibility: Ensuring compatibility between the aluminum paste and the existing coating is critical. Mismatched chemical or physical properties can result in poor adhesion and reduced coating performance.

- Curing Agent Selection: The choice of curing agent and ratio must be appropriate for the original and new coatings. Incorrect selection or mixing ratios can adversely affect the final adhesion and durability.

Conclusion

Choosing the right type of aluminum paste is essential for ensuring the performance and appearance of coatings. Leafing aluminum paste offers high reflectivity and a chrome-like finish, making it suitable for applications requiring high gloss and corrosion resistance. However, its tendency for flake detachment limits its use in multiple coatings. Non leafing aluminium paste provides strong adhesion, stability, and versatility, making it ideal for a wide range of applications, from automotive finishes to furniture coatings. Understanding the characteristics, applications, and factors affecting adhesion of these types of aluminum paste enables better decision-making for industrial and commercial uses, ensuring optimal results in coating performance and aesthetics.