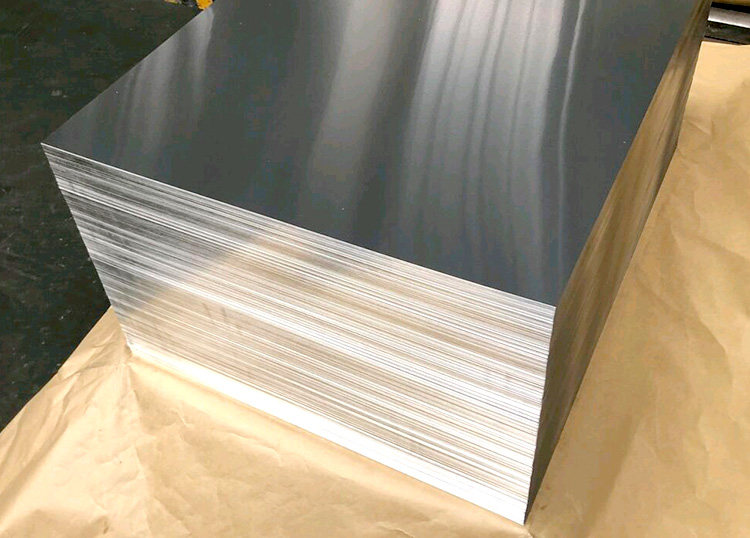

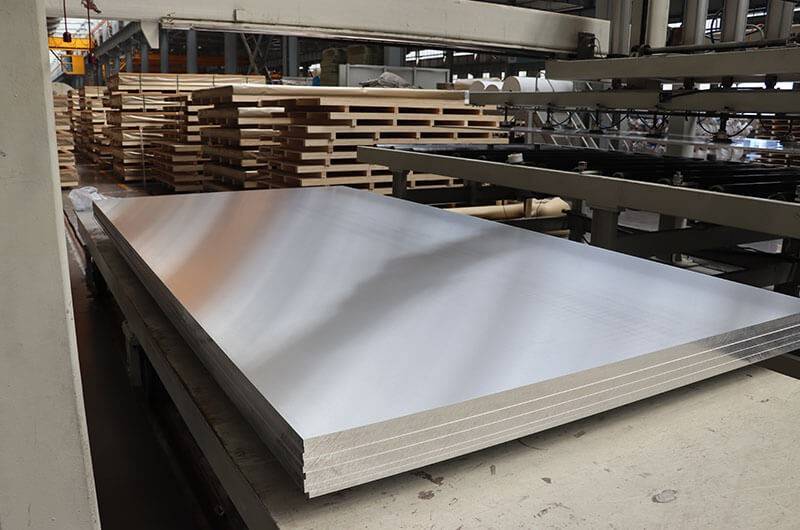

6061 aluminum sheet, a versatile and widely used material in industries ranging from aerospace to construction, offers a unique blend of strength, corrosion resistance, and machinability. However, the performance of 6061 aluminum isn’t solely determined by its composition but also by its material state, which is influenced by heat treatment and mechanical processing. This article delves into the common material states of 6061 aluminum, their properties, and their best-suited applications.

What are the Main Temper States in 6061 Aluminum Sheets?

The different material states of 6061 aluminum sheets are obtained through different heat treatment and processing processes, which affect the mechanical properties, hardness, ductility and corrosion resistance of aluminum plates.The material state not only determines the application range of aluminum sheet, but also affects its processing method and the performance of finished products. The common 6061 aluminum sheet material states are mainly O state, T4 state, T6 state, T651 state, F state and H112 state.

Let’s delve deeper into these temper states and their characteristics:

1. O-State (Annealed State)

The O-state refers to aluminum that has been fully annealed. In this state, the sheet has been subjected to heat treatment that softens the material, increasing its ductility and making it easier to shape and form. The annealing process involves heating the aluminum sheet to a temperature that allows the grain structure to become uniform, followed by cooling at a controlled rate. This results in a material with low strength but excellent workability.

Properties of O-State Aluminum Sheet:

- Low strength: The strength of O 6061 sheet is much lower compared to other states.

- High ductility: The material is very flexible and easy to deform, making it ideal for further processing.

- Excellent formability: It can be easily stretched, rolled, or bent without cracking, making it suitable for complex shapes.

Applications: The O 6061 aluminum sheet is commonly used in scenarios requiring extensive deformation, such as deep drawing, bending, and stretching. It is particularly suited for industries where components must be shaped or formed prior to further processing. Typical applications include:

- Aluminum foil production

- Thin-walled components

- Products that demand significant forming processes

2. T4-State

T4-state aluminum has undergone a solution heat treatment (also known as solid solution treatment), followed by air cooling. This treatment results in a material with higher strength than O-state aluminum while still maintaining relatively good ductility and formability. T4 aluminum sheet is considered to be in the “natural” or “as-quenched” state, which means it has not undergone the artificial aging process that follows the heat treatment. As a result, the strength is lower compared to fully aged T6 aluminum, but the material retains good malleability.

Properties of T4-State Aluminum Sheet:

- Higher strength: Compared to O-state, T4 aluminum has significantly higher tensile strength.

- Moderate ductility: While the strength is increased, T4 aluminum retains sufficient ductility for many applications.

- Good formability: T4 aluminum is still relatively easy to shape, though it is harder than O-state material.

Applications: The 6061 T4 aluminum sheet is ideal for applications that demand a balance between strength and formability. It is extensively used in industries requiring materials that combine durability with ease of processing. Common applications include:

- Structural components in aerospace

- Vehicle frames in automotive manufacturing

- Construction parts

- Components requiring further processing, such as welding or machining

3. T6-State

T6-state aluminum is produced by solution heat treatment followed by artificial aging. This process significantly increases the aluminum sheet’s strength by precipitating out strengthening phases, primarily magnesium silicide, within the aluminum matrix. The result is a material with high tensile strength and hardness but lower ductility and formability compared to T4 or O states.

Properties of T6-State Aluminum Sheet:

- High strength: T6 aluminum offers very high tensile strength, making it one of the strongest variants of 6061 aluminum.

- Reduced ductility: While the strength is greatly enhanced, ductility and formability are reduced, making the material harder to process.

- Good dimensional stability: The artificial aging process imparts dimensional stability, making T6 aluminum resistant to changes in shape during later processing stages.

Applications: The 6061 T6 aluminum sheet is ideal for applications where high strength is essential, even if reduced ductility is acceptable. It is commonly used in industries that demand materials with superior structural integrity. Typical applications include:

- Aircraft components in aerospace

- Structural parts for ships in marine industries

- High-strength mechanical components in high-performance automotive manufacturing

- Extrusions requiring exceptional structural integrity

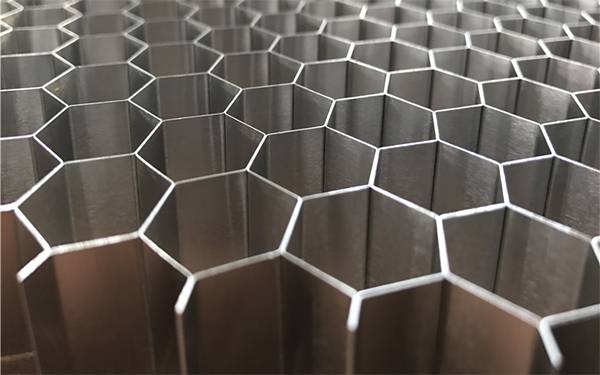

4. T651-State

The T651 state is essentially a modified version of T6-state aluminum. After the aluminum sheet is solution heat-treated and artificially aged (as in the T6 process), the T651 treatment involves a further stress-relief process to minimize internal stresses that could cause warping or distortion during machining. This additional step helps maintain dimensional accuracy and minimizes the likelihood of deformation in later stages of processing.

Properties of T651-State Aluminum Sheet:

- High strength: T651 aluminum retains the high strength and hardness characteristics of T6 aluminum.

- Dimensional stability: Due to the stress-relief step, T651 aluminum has superior dimensional stability, making it less likely to warp or distort during machining.

- Reduced internal stresses: The stress-relief process reduces the internal stresses caused by the initial heat treatment, ensuring the material maintains its shape during machining and assembly.

Applications: The 6061 T651 aluminum sheet is well-suited for precision machining applications that require both high strength and tight dimensional tolerances. Common applications include:

- Aerospace structural components

- Precision machinery parts

- Automotive components requiring exact dimensions

- Parts where maintaining dimensional accuracy during processing is critical

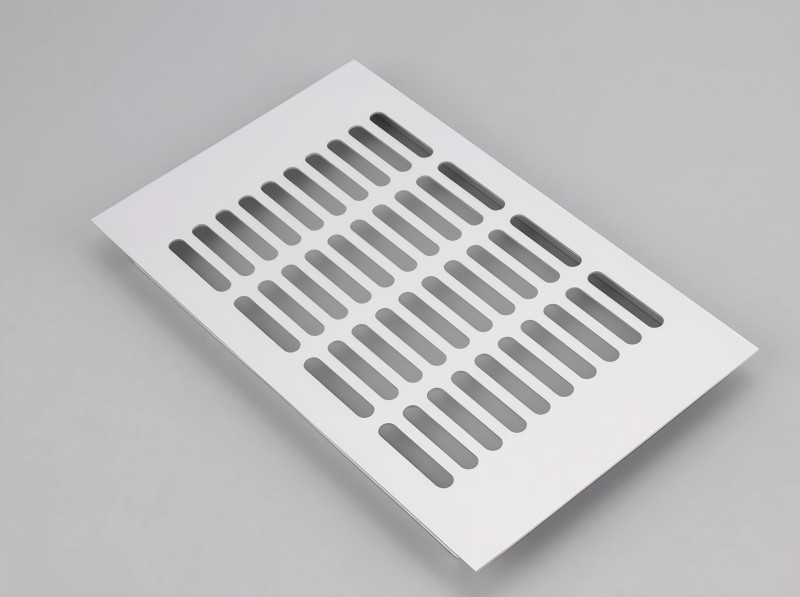

5. F-State (As-Fabricated)

F-state aluminum is essentially the as-fabricated or as-rolled material that has not undergone significant heat treatment. This state can include materials that are either lightly cold worked or not processed at all. F-state aluminum has relatively low strength but retains its original properties, including excellent ductility.

Properties of F-State Aluminum Sheet:

- Low strength: F-state aluminum does not have the enhanced strength provided by heat treatment.

- High ductility: The material maintains its original ductility and formability, allowing it to be further processed with ease.

- No significant heat treatment: F-state aluminum is essentially in its as-fabricated form, which means it is often used for initial stages of manufacturing before additional treatment.

Applications: F-state aluminum sheet is ideal for applications that prioritize ease of handling and processing over strength. Typical uses include:

- Non-structural components

- Packaging materials

- Parts intended for further processing, such as welding or heat treatment

6. H112-State

H112 aluminum is a condition in which the material has undergone light cold working and has been heat treated to a slight degree to enhance its strength. While not as strong as T6 or T651 aluminum, H112 aluminum offers better mechanical properties than O-state aluminum and is suitable for less demanding structural applications.

Properties of H112-State Aluminum Sheet:

- Improved strength: H112 aluminum has better strength than O-state aluminum but is less strong than T6 or T651.

- Good workability: The material retains good workability and can be easily processed for many applications.

- Intermediate properties: The strength and ductility fall between the low-strength O-state and the high-strength T6, making it suitable for a variety of uses.

Applications: H112 aluminum is commonly employed in general engineering applications where moderate strength and good workability are required. Typical uses include:

- Machine parts

- Structural components in buildings

- Vehicle components

- Manufacturing processes requiring moderate strength and ease of handling

Summary Table of the Comparison for Different Tempers

| Temper State | Strength | Hardness | Ductility | Application Example |

| O (Annealed) | Low | Low | High | Deep-drawn parts |

| T4 | Medium | Medium | High | Aircraft structures |

| T6 | High | High | Medium | Aerospace & structural components |

| T651 | High | High | Medium | Precision machining |

| F | Low | Low | High | Low-stress parts |

| H112 | Medium | Medium | Medium | General engineering |

Final Thoughts

The various material states of 6061 aluminum sheets, including O, T4, T6, T651, F, and H112, each offer distinct mechanical properties suited for different applications. Understanding the strengths and limitations of each state is essential for engineers and manufacturers when selecting materials for specific uses. By selecting the right material state, one can optimize performance, cost-efficiency, and manufacturability in a wide range of industries, from aerospace to automotive, construction, and more. Choosing the correct 6061 aluminum sheet state ensures that the material meets the design and performance criteria required for the success of the project.