Aluminium Heat Sink for LED Strip

LED strips are an incredibly popular lighting solution for both residential and commercial applications, thanks to their flexibility, energy efficiency, and low heat output. However, even LED strips can generate…

Aluminium Louver: The Perfect Window Treatment for Your Business

As a business owner, you know how important it is to create a comfortable and welcoming environment for your customers and employees. One of the key elements of any commercial…

Aluminium Foil: Tips, Applications, and Industry Insights

Aluminium foil has been a household staple for decades, valued for its versatility, durability, and affordability. From wrapping food to protecting electronics, aluminium foil has countless applications in our daily lives…

6 Main Differences Between Regular Aluminum Foil and Heavy Duty Aluminum Foil

Aluminum foil is a kitchen staple that has been used for decades to store, cook, and transport food. It is a thin, pliable sheet made from aluminum, and is often used…

2024 Aluminum Plate VS. 6061 Aluminum Alloy Plate: Properties, Applications, and Difference

Various industries use aluminum alloys due to their high strength, lightweight and corrosion resistance. Among the most commonly used aluminum alloys are 2024 and 6061, which are widely used in the aerospace,…

Customizing Aluminum Profiles with Surface Fishing

Aluminum profiles are widely used in various industries due to their exceptional properties such as durability, lightweight, and versatility. They are commonly used in construction, transportation, and manufacturing, and come in…

Aluminum Foil Containers VS Plastic Containers for Food Storage

In today’s fast-paced world, the need for convenient and efficient food storage solutions has become increasingly important. With the rise of takeout and delivery services, many people are opting for…

Aluminum Shelves: The Lightweight and Durable Storage Solution

If you’re looking for a versatile and durable storage solution, aluminum shelves may be just what you need. Made from a lightweight yet strong material, aluminum shelves offer a range of…

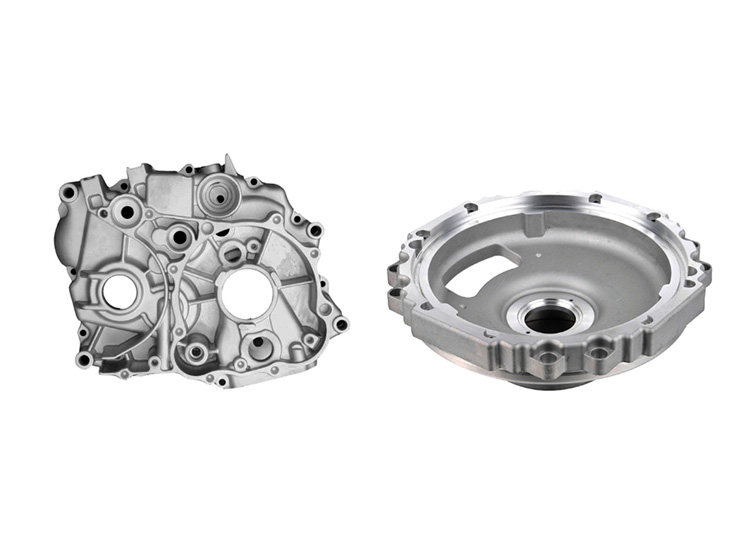

Aluminium Die Casting Parts: The Benefits of Customization and Expertise

Innovation and technology have transformed the manufacturing industry, providing new solutions for complex problems. The aluminium die-casting industry is no exception, with advances in technology and new materials leading to…

5 Processes of Aluminum Coil Production: From Ingot to Coiled Product

Aluminum is a widely used material in a variety of industries, and one of the most common forms of aluminum is the aluminum coil. An aluminum coil is a long,…

Design Considerations for Aluminum Machining Parts: A Guide to Creating Efficient and Effective Products

Aluminum is a versatile material that is commonly used in the manufacturing industry due to its lightweight, corrosion-resistant, and easy-to-machine properties. However, designing aluminum machining parts can be challenging, and requires…

Aluminum Stamping VS Aluminum Die Casting

Aluminum stamping and aluminum die casting are two popular manufacturing processes used for producing aluminum parts. Both processes have their unique advantages and disadvantages, making it essential to choose the right one…