What are Aluminum Honeycomb Panels?

As new building exterior walls continue to evolve, dry-hanging facades made of aluminum curtain walls are becoming increasingly popular, surpassing traditional materials such as stone and emerging as a new…

Aluminum Strip Gussets – Surface Treatment Processes and Development Prospect

In modern buildings, you’ll often notice aluminum strip gusset ceilings when you look up. These are a common type of metal ceiling known as aluminum strip ceilings. A newer type…

Applications of Aluminum Plates in Architectural Design

Aluminum plates are widely used in architectural landscape design, ranging from large building facades to small partitions of landscape walls. Aluminum plates may be used when the metal decoration is…

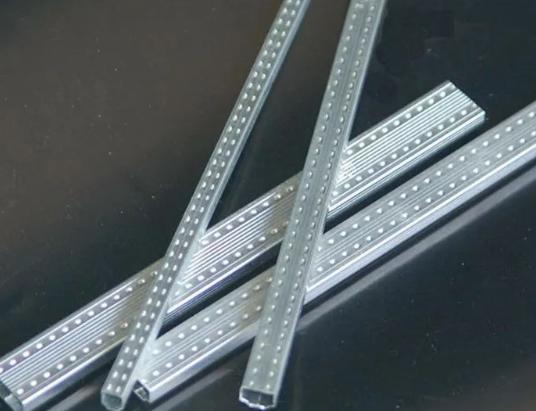

Aluminum Plastic Film – The Key Material For Encapsulating Pouch Batteries

The aluminum plastic film is a crucial material in the lithium battery industry chain’s upstream packaging, representing 10-20% of total material cost for pouch batteries. Compared to other battery materials…

5 Tips for Maintaining Aluminum Alloy Doors and Windows

It is particularly important to perform maintenance and repairs on aluminum alloy doors and windows at the end of the year. This article will provide tips on proper maintenance to…

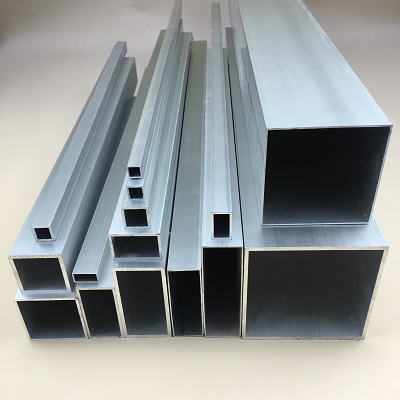

6 Tips To Buy a Hollow Aluminum Bar

The hollow aluminum bar (hollow aluminum strip) is widely used on many occasions. To help you know aluminum hollow bars quickly and get aluminum hollow bars correctly, this article will introduce…

3 Questions To Know Aluminum Can

Aluminum cans are cans which are made of aluminum coils. The aluminum can is composed of a can lid, a pull ring, a can body and a can bottom. Aluminum cans…

Aluminum Alloy Door And Window: What Is And How To Choose?

Doors and windows are an indispensable part of homes. When it comes to doors and windows, many individuals pick aluminum alloy doors and windows. The decorative effect of aluminum alloy…

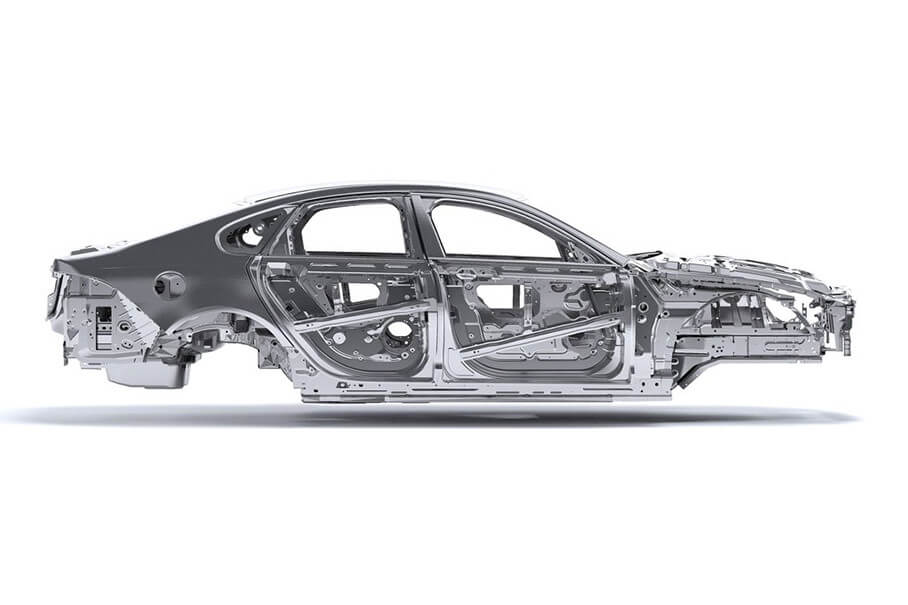

Application of Aluminum Profiles in New Energy Vehicles

Why use aluminum profiles in new energy vehicles? In recent years, the new energy vehicle industry has developed rapidly. Different from traditional vehicles, new energy vehicles use batteries as their…

5 Advantages You Do Not Know About Aluminum Square Tube

Aluminum Square Tube is an extruded aluminum material with a very wide range of uses and applications. It has excellent corrosion resistance, good processability, and good machinability, and is trusted by…

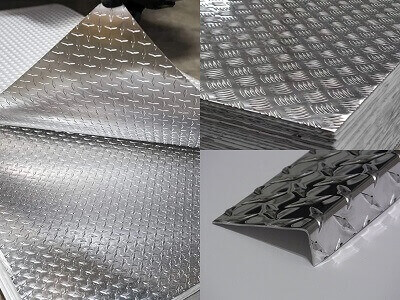

3 Ways to Choose Aluminum Diamond Plate

1. What is aluminum diamond plate? Aluminum plate refers to a rectangular plate processed by rolling aluminum ingots, divided into aluminum pure plate, aluminum alloy plate, aluminum thin plate, aluminum…

Advantages and Treatment Process of Aluminum Cans

As for cans, there are 2 types of cans: aluminum cans and iron cans. The output of aluminum cans in China has reached 55 billion, with an average of 40…