5A83 Aluminum Cast Plate

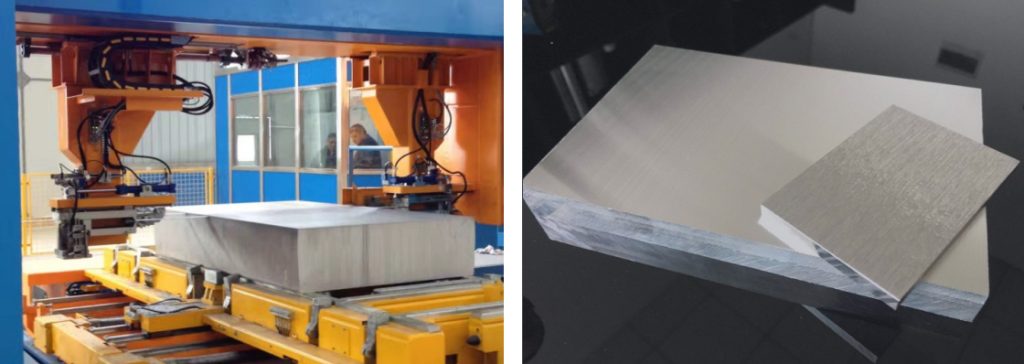

CHAL 5A83 aluminum cast plate, also known as aluminum cast tooling plate, aluminum cast mold plate, and cast aluminum tool & jig plate, is an improved aluminum alloy plate of 5083, which was developed exclusively by CHAL and introduced in 2012. CHAL 5A83 aluminum cast plate is a vertical cast, stress-relieved, extraordinarily dense, dimension stable, high strength(without heat treatment) machined plate providing sound dimensional stability with minimal or no distortion even after extensive machining operations.

CHAL 5A83 Aluminum Cast Plate

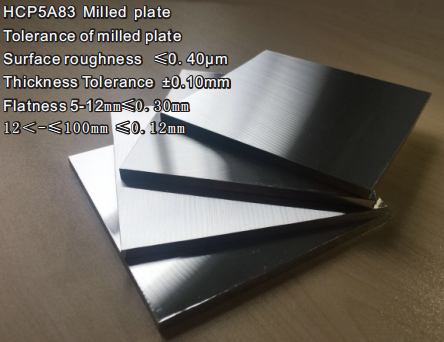

CHAL 5A83 aluminum cast plates have precision machined surfaces for superior flatness, flat within 0.3mm, and +/- 0.1mm thickness tolerance, and are protected with PVC plastic on two sides. Cast aluminum plate typically has a surface roughness of 0.4µm Ra or better. CHAL 5083 aluminium cast plate has a tensile strength of 41KSI, a Hardness of 70HB, and a Yield Strength of 18 KSI.

CHAL aluminum cast plate has outstanding machinability and responds very well in today’s high-speed cutting environments. It is the preferred choice for engineers that require a dimensionally stable product that has a great strength-to-weight ratio. The cast plate is designed especially for the growing high-temp plastic and mold & tool industries.

The Reasons for Choosing 5A83 Aluminum Cast Plate as Mold & Tool & Jig Material

- The CHAL 5A83 aluminum cast plate is more cost-effective than the wrought aluminum plate and tool steel.

- Aluminum cast plate lowers real-time production costs through machinability advantages.

- Compared with aluminum mold/ tool plate, tool steels are too hard.

- Compared with cast 5A83 aluminum cast plate, wrought alloys are too soft and gummy.

- Compared with rolled plate, CHAL 5A83 precision-milled aluminum cast plate has a finer and more homogeneous grain structure, with a specific state of stress-relieving, which makes there is almost no deformation after the high speed of machining and cutting. However, the rolled plate has a directional structure, striped grain distributes along the processing direction. They’re always showing some deformations after machining.

- Steels and wrought alloys increase tool costs and machine time, except for the CHAL 5A83 aluminum cast plate.

- CHAL 5A83 aluminum plate has exceptional corrosion resistance properties and weldability.

The World Trade Names of 5A83 Cast Aluminum Plate for Mold & Tooling & Jig

Our quality standard is one of the highest standards in the industry.

Similar products are known by various trade names in the world:

- Mic 6® (a registered trademark of Aloca Inc)

- 5052-H112-high precision(Kobe Steel)

- Alimex ACP5080

- Alpase K100-S® (a registered trademark of TST, Inc)

- Alca 5™ (a trademark of PCP Canada)

- Vista Metals ATP 5™ (a trademark of Vista Metals Corp)

- Alimex 5083

- Vista Metals ATP-5™

8 Characteristics of 5A83 Fine Milled Aluminum Cast Plate

- Almost no deformation for machining, excellent formability, and weldability.

- Easy to process, good effect of surface treatment.

- High strength, good corrosion resistance, and oxidation resistance.

- Isotropic homogeneity, and excellent dimension stability.

- Fine milling surface as a requirement. Good surface quality.

- Double-sided filmed.

- High-temperature performance is excellent.

- The internal performance of the plate is the same as the external.

Applications of 5A83 Fine Milled Aluminum Cast Plate

CHAL aluminum cast mold & tooling plate applications include, but are not limited to, Computer & Electronics, Pharmaceuticals, Machining Fixtures, Drill Jigs, Index Tables, Semi-Conductor, Automotive Molds, CNC circuit boards, various instruments, tools electronic equipment, food machinery, plastic injection mold, PV industry, medical instruments, packaging machinery and model, pharmaceutical machinery, printing machine, robot, decorative material, a detection device, optical equipment, ship, subway, aviation industry, ship, subway, aviation industry, etc.

Performance and Parameters of 5A83 Fine Milled Aluminum Cast Plate

| Aluminum Alloy | 5A83 (improved grade 5083) Material feature: casting, homogeneity Type: precision-milled or band-sawed cut |

| Material Properties | Machinability: very good Weldability (TIC, MIG): good Anodic oxidation properties: good, not decorative Polishability: very good Corrosion resistance: very good WEDN machining: good |

| Typical Mechanical Properties | Tensile strength (Rm): 240-290MPa (N/mm²) 0.2% Yield strength (Rp0.2): 110-130MPa (N/mm²) Breaking elongation (A 5%): 12 Brinell hardness HBW: 70 |

| Typical Physical Properties | Density: 2.69g/cm³ Thermal conductivity: 110-140W/ (mK) Electrical conductivity: 16-19MS/m (m/ Ωmm²) Elastic modulus: ~ 70, 000N/mm² Coefficient of thermal expansion: 24.2*10-6/K |

| Sizes and Thickness Range | Cast plate thickness: 5mm -100mm Standard pre-cut sizes: Thickness*max. Width* max. Length* ≥5mm x 1320mm x 3020mm ≥5mm x 1520mm x 3020mm ≥10mm x 1570mm x 3670mm ≥15m x 1860mm x 4000mm Other dimensions available for inquiring |

| Tolerance | Surface roughness (precision milled): Ra < 0.4µm Thickness tolerance: +/-0. 05mm Flatness: (6mm-12mm)≤0. 30mm (12mm- 100mm)≤0.12mm Width tolerance: 0/+10 mm Length tolerance: 0/+15 |

Finely milled aluminium cast plates and precision sawed cast aluminum plates are available. Tinted oxidation is also an option for customers, our cast aluminum plate can be produced in custom widths and lengths with a very short lead time.

As a leading aluminum company in China, CHAL Precision Aluminium Corporation has a variety of aluminum plates, rolled and cast. There are multiple choices of aluminum plate for mold and machinery, such as 2024-T351, 6061-T651, 5052-O/H111/H112, 6063-T651, 5A83, 5083 O/H111/H112,7075-T651, 6082-T651. At the same time, we constantly develop new products to meet the needs of customers. we specially developed high-precision aluminum cast plates for mold and tooling, there are 2 kinds of cast plates, fine-milled aluminum cast plates and precision sawed cast aluminum plates.

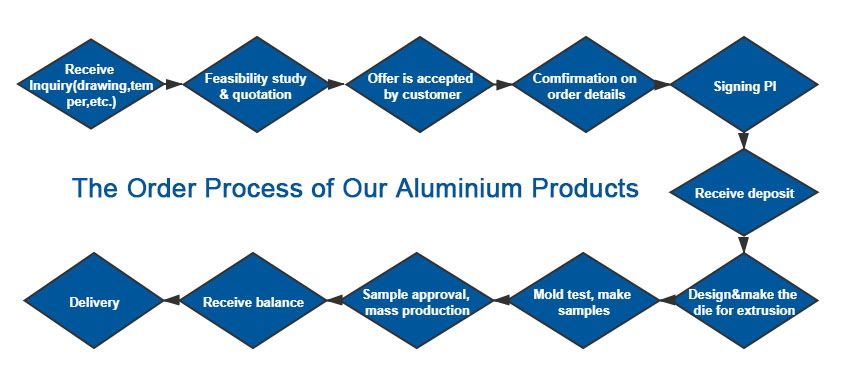

Order Process of 5A83 Aluminum Cast Plate