Aluminium foil has been a staple in various industries for its versatility and effectiveness in sealing products. This thin, flexible metal sheet is renowned for its ability to provide an airtight barrier, ensuring the preservation and protection of a wide range of items. This article delves into the reasons for using aluminium foil for sealing, the methods employed, its applications, and where to source high-quality aluminium foil.

Reasons for Aluminium Foil for Sealing

Aluminium foil is favoured for sealing due to its unique properties and numerous advantages:

1. Superior Barrier Protection

- Moisture Barrier: Aluminium foil is impervious to water and steam, making it an excellent barrier against moisture. This property is crucial for keeping food, pharmaceuticals, and other perishable products dry and free from contamination.

- Oxygen Barrier: Aluminium foil effectively prevents oxygen from penetrating the packaging. This is essential for preserving the freshness and shelf life of oxygen-sensitive products, such as food and certain chemicals, by preventing oxidation and spoilage.

- Light Barrier: Aluminium foil provides a complete barrier to light, including ultraviolet (UV) rays. This is particularly important for products that are sensitive to light, such as certain medications, cosmetics, and food items, as it helps maintain their quality and efficacy.

- Contaminant Barrier: Aluminium foil’s non-porous nature prevents contaminants, including bacteria, viruses, and dust, from entering the sealed package. This ensures the integrity and safety of the contents.

2. Versatility and Flexibility

- Conformability: Aluminium foil is highly flexible and can be easily molded to fit various shapes and sizes of containers and packaging. This makes it suitable for a wide range of applications, from sealing small blister packs to covering large trays.

- Adaptability: It can be used with different sealing methods, such as heat sealing, induction sealing, pressure sealing, and crimp sealing. This adaptability allows manufacturers to choose the most appropriate sealing technique for their specific needs.

- Customizability: Aluminium foil can be laminated with other materials, such as plastic or paper, to enhance its properties and meet specific requirements. This customizability makes it ideal for specialized applications where additional strength, puncture resistance, or printability is needed.

3. Cost-Effectiveness

- Material Efficiency: Aluminium foil is relatively inexpensive to produce and use. Its lightweight nature means that less material is required for effective sealing compared to other options, reducing overall packaging costs.

- Durability: Despite its thinness, aluminium foil is remarkably strong and resistant to tearing and puncturing. This durability translates to fewer packaging failures, reducing waste and associated costs.

- Long-Term Savings: The protective qualities of aluminium foil help extend the shelf life of products, minimizing spoilage and waste. This leads to cost savings for both manufacturers and consumers by reducing the need for frequent replacements and ensuring product availability for longer periods.

4. Sustainability

- Recyclability: Aluminium foil is 100% recyclable, making it an environmentally friendly packaging choice. Recycling aluminium saves up to 95% of the energy required to produce new aluminium from raw materials, significantly reducing the environmental impact.

- Resource Efficiency: The production of aluminium foil involves minimal waste, and its recycling process is highly efficient. This aligns with the growing demand for sustainable packaging solutions and helps companies meet their environmental goals.

- Reduced Carbon Footprint: Using recycled aluminium foil contributes to a lower carbon footprint compared to using virgin materials. This is important for companies looking to improve their sustainability credentials and reduce their impact on climate change.

5. Compliance and Safety

- Food Safety: Aluminium foil is non-toxic and safe for direct contact with food. It does not react with food products, ensuring that the taste, aroma, and nutritional value of the food are preserved.

- Pharmaceutical Standards: In the pharmaceutical industry, aluminium foil meets stringent regulatory standards for packaging materials. It provides a reliable barrier against moisture, oxygen, and contaminants, ensuring the safety and efficacy of medications.

- Tamper-Evidence: Certain sealing methods using aluminium foil, such as induction sealing, offer tamper-evident features. This is crucial for consumer safety, as it ensures that the product has not been opened or tampered with before reaching the end-user.

In conclusion, aluminium foil is a highly effective sealing material due to its superior barrier protection, versatility, cost-effectiveness, sustainability, and compliance with safety standards. These attributes make it an indispensable choice for various industries, ensuring the integrity, safety, and longevity of sealed products.

Methods of Aluminium Foil for Sealing

When use aluminium foil for sealing, there are several sealing methods and each method offers unique benefits and is suited for specific applications. Here are the primary methods:

1. Heat Sealing

Heat sealing is a widely employed method that involves the application of heat and pressure to a heat-sealable aluminum foil layer. This process causes the foil to fuse with the packaging material, forming a robust seal. Typically executed using specialized heat sealing machines equipped with sealing bars, this method is recognized for its speed, efficiency, and suitability for large-scale production.

Key benefits:

- High-speed production: Suitable for large-scale packaging operations.

- Strong seals: Creates reliable and durable closures.

- Versatility: Can be used with various packaging materials.

Applications:

- Food Packaging: Heat sealing is widely used in the food industry for sealing ready-to-eat meals, snacks, and dairy products. It ensures that the food remains fresh and protected from external contaminants.

- Pharmaceutical Packaging: This method is also used for sealing blister packs and pouches containing medications, ensuring they remain sterile and tamper-proof.

- Cosmetic Packaging: Heat sealing is employed to secure products like creams and lotions, protecting them from contamination and extending their shelf life.

2. Induction Sealing

Induction sealing leverages electromagnetic induction to generate heat within a thin aluminum foil liner positioned on a container’s cap or closure. The intense heat causes the foil to melt and form a hermetic seal upon cooling. This method is renowned for its tamper-evident properties, making it ideal for products requiring high security.

Key benefits:

- Tamper-evident: Provides evidence of product tampering.

- High barrier properties: Effectively protects against contaminants.

- Wide range of applications: Suitable for liquid, semi-solid, and dry products.

Applications:

- Pharmaceuticals: Induction sealing is commonly used for tamper-evident seals on medicine bottles, ensuring the product has not been compromised.

- Food and Beverage: This method is used to seal jars and bottles of liquids, sauces, and other food products, preserving freshness and preventing leaks.

- Chemical Products: Induction sealing is suitable for sealing containers of chemicals, oils, and other industrial products, providing a leak-proof and secure seal.

3. Pressure Sealing

Pressure sealing involves the application of mechanical pressure to bond the aluminum foil to the packaging material, often with the assistance of an adhesive layer. This method offers versatility as it can be applied to both rigid and flexible packaging.

Key benefits:

- Versatility: Can be used with various packaging materials and shapes.

- Strong seals: Provides reliable closure even under challenging conditions.

- Cost-effective: Relatively simple and inexpensive process.

Applications:

- Snack Packaging: Pressure sealing is often used for sealing snack bags and pouches, ensuring the contents remain crispy and fresh.

- Frozen Foods: This method is suitable for sealing frozen food packages, protecting them from freezer burn and moisture.

- Dry Goods: Pressure sealing is used for packaging dry goods like cereals and grains, maintaining their quality and extending shelf life.

4. Crimp Sealing

Crimp sealing entails folding and crimping the aluminum foil around the edges of the packaging material to create a mechanical seal. This method typically necessitates specialized crimping equipment and is commonly used for tubular packaging.

Key benefits:

- Cost-effective: Simple and inexpensive process.

- Tamper-evident: Provides visual indication of product tampering.

- Suitable for tubular packaging: Ideal for tubes and cartridges.

Applications:

- Tube Sealing: Crimp sealing is widely used for sealing the ends of tubes containing toothpaste, ointments, and gels, providing a tamper-evident and airtight seal.

- Confectionery Packaging: This method is used for wrapping chocolates and candies, protecting them from moisture and maintaining their shape.

- Industrial Products: Crimp sealing is suitable for sealing tubes and containers of industrial adhesives, lubricants, and other products that require a strong and secure seal.

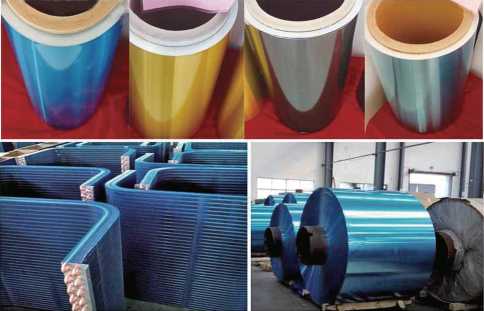

Get Aluminium Foil for Sealing From CHAL

CHAL is a trusted source of high-quality aluminium foil suitable for sealing applications. CHAL offers a wide range of aluminium foil products tailored to meet the diverse needs of various industries. Their aluminium foil is manufactured to the highest standards, ensuring optimal performance and reliability.

Whether you need aluminium foil for food packaging, pharmaceutical sealing, or industrial applications, CHAL provides products that deliver exceptional barrier protection, versatility, and cost-effectiveness. By choosing CHAL, you can be confident in the quality and performance of your sealing solutions. Feel free to contact them here.