In the realm of contemporary design and technology, the marriage of form and function has never been more profound than in the realm of lighting. With the advent of LED technology, designers and engineers are exploring innovative ways to not only illuminate spaces but also shape the very essence of design itself. At the forefront of this revolution is the versatile aluminum LED casing, a material that not only enhances the performance of LED lights but also opens up a world of possibilities in design aesthetics.

The Rise of LED Technology:

Light Emitting Diode (LED) technology has rapidly evolved over the past few decades, becoming the preferred choice for lighting solutions due to its energy efficiency, longevity, and design flexibility. LEDs emit light in a highly directional manner, making them ideal for a range of applications from ambient lighting to architectural accents.

Aluminum: The Ideal Companion for LEDs

Aluminum has emerged as the material of choice for LED casing, and for good reason. Its remarkable properties, including lightweight, excellent thermal conductivity, and corrosion resistance, make it an ideal companion for LED technology.

6063-T5 and 6061-T6 is the most common alloy used in LED casings. They both are a good general-purpose alloy that is strong, lightweight and has excellent corrosion resistance. 6061-T6 is stronger than 6063-T5 and has better fatigue resistance. It is often used in LED casings that need to be more durable, such as those used in outdoor or industrial applications.

Aluminum’s ability to dissipate heat effectively ensures the longevity and optimal performance of LEDs, addressing a common concern in lighting design.

1. Versatility in Design

One of the most significant advantages of aluminum LED casing lies in its versatility in design. Aluminum is a highly malleable material, allowing designers to craft sleek, modern fixtures or intricate, ornate structures with ease. The material’s adaptability opens up a plethora of possibilities for creating lighting solutions that seamlessly integrate with diverse architectural styles and interior designs.

2. Precision Engineering for Optimal Performance

Aluminum LED casing is not only about aesthetics but also about precision engineering to achieve optimal performance. The material’s ability to be precisely machined ensures that LED components fit seamlessly, providing a secure and efficient environment for the LEDs to operate. This precision engineering not only enhances the functionality of the lighting but also contributes to the overall reliability and durability of the fixtures.

3. Energy Efficiency and Sustainability

The environmental impact of design choices is becoming increasingly crucial in today’s world. Aluminum’s sustainability as a material, coupled with the energy efficiency of LED technology, makes aluminum LED casing an eco-friendly choice. Designers can align their creative vision with sustainability goals, creating lighting solutions that not only look good but also contribute to a greener future.

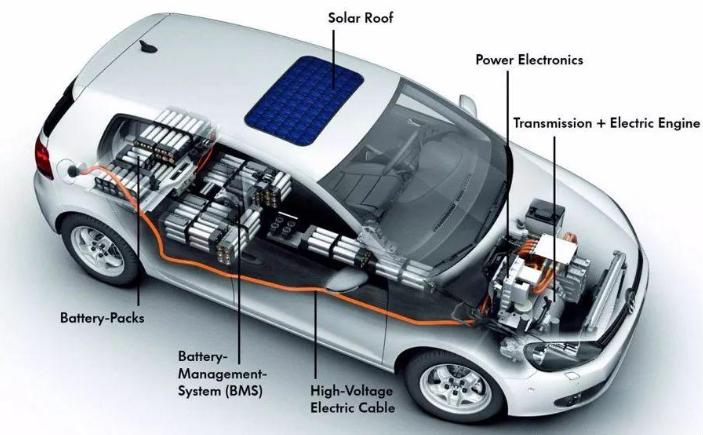

4. Applications Across Industries

The versatility of aluminum LED casing extends beyond residential and commercial spaces. Industries such as automotive, aviation, and outdoor lighting benefit from the combination of aluminum and LED technology. The lightweight yet robust nature of aluminum makes it an excellent choice for applications where durability and weight considerations are paramount.

Conclusion

As we continue to push the boundaries of design and technology, the synergy between aluminum LED casing and LED technology stands as a testament to the limitless possibilities in shaping light and design. The marriage of form and function, aesthetics, and efficiency, makes aluminum LED casing a key player in the evolution of lighting solutions. Designers, engineers, and enthusiasts alike are invited to explore the vast potential of aluminum LED casing as they continue to shape the way we perceive and interact with light in our ever-evolving world.