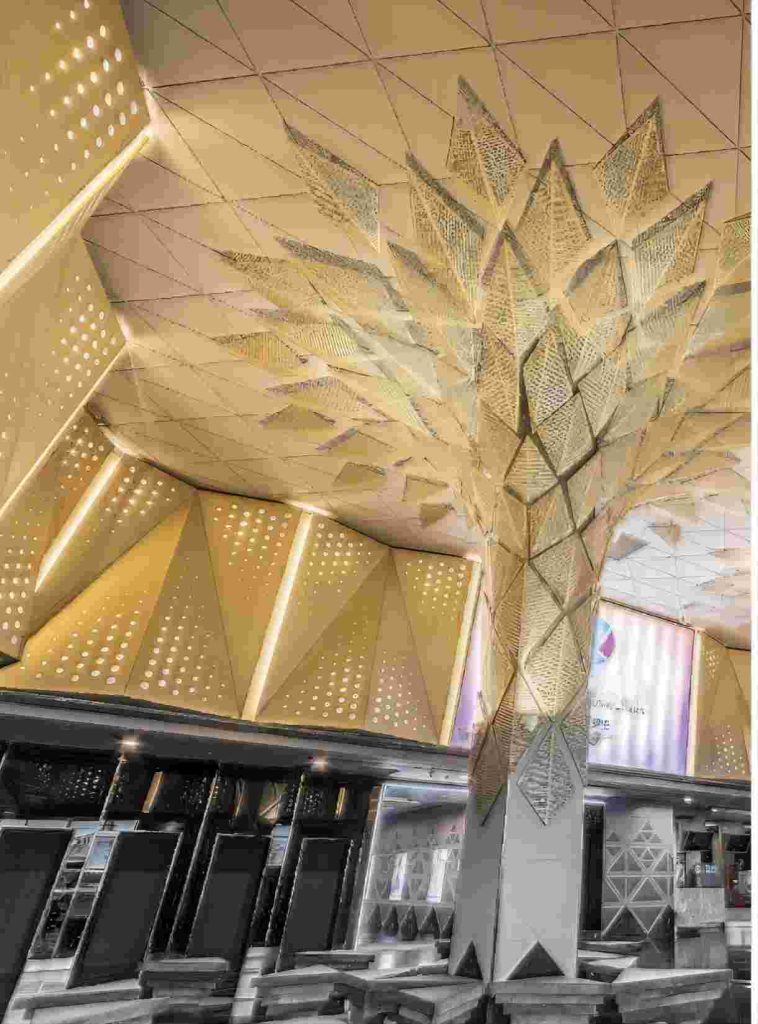

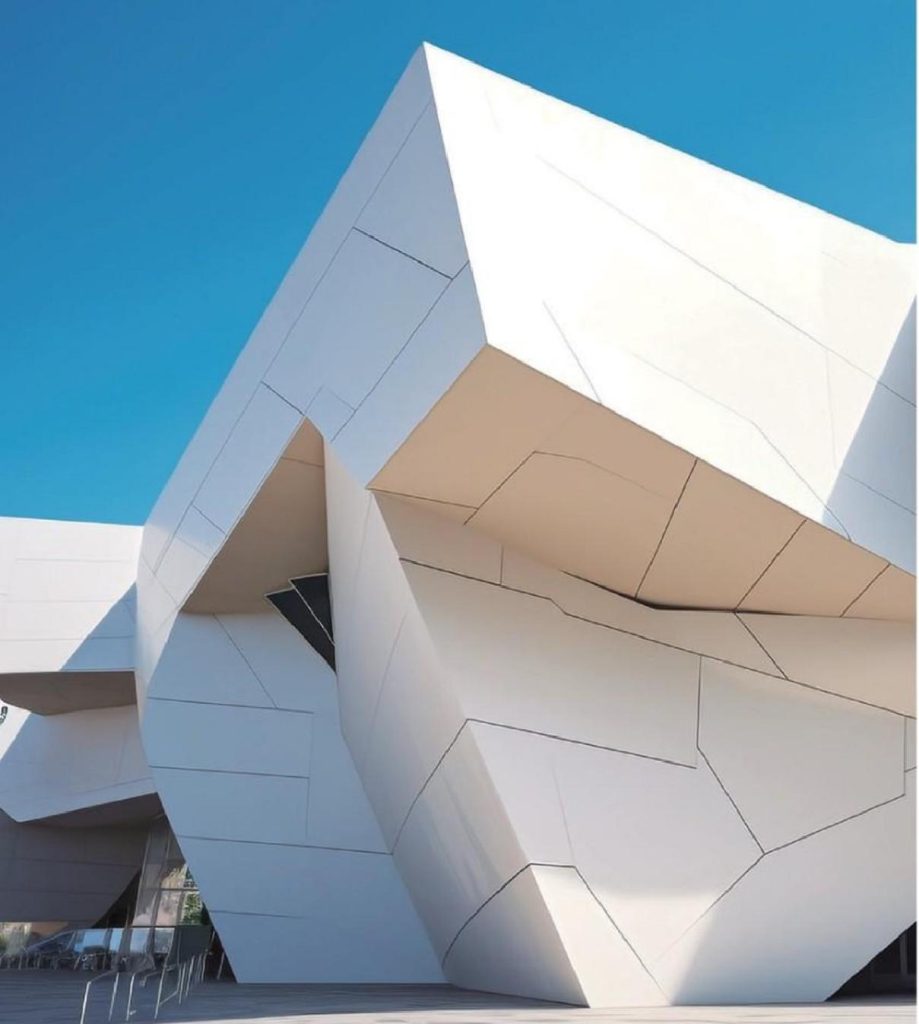

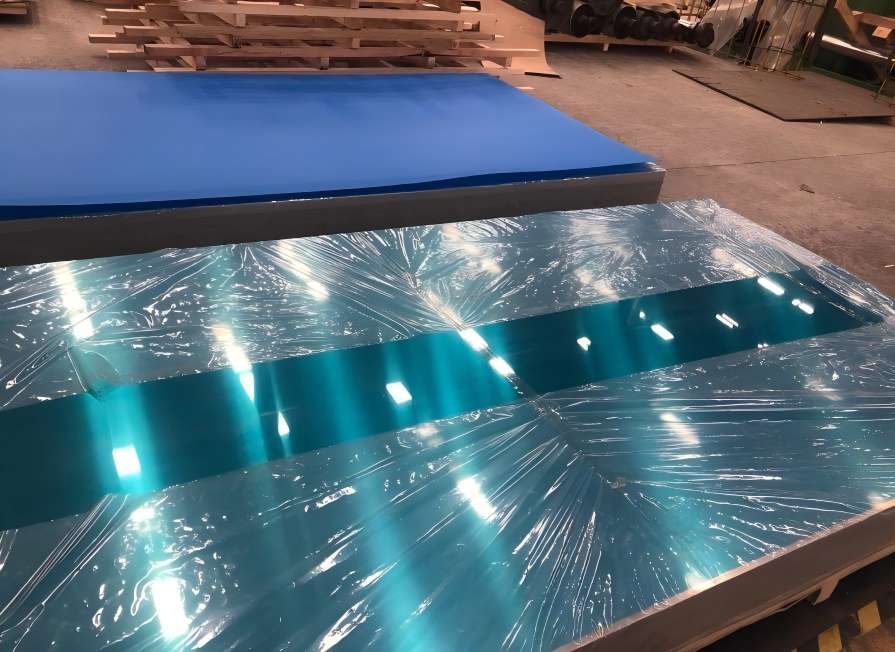

Pre-painted aluminum sheets offer a versatile and attractive solution for various applications, from architectural facades and roofing to automotive components and consumer goods. However, like any material, they are susceptible to certain issues that can impact their appearance, durability, and performance. This article will delve into some of the most common problems encountered when using pre-painted aluminum sheets and explore effective preventative measures for smooth and successful usage.

Problem 1: Coating Defects

The coating on pre-painted aluminum sheets is critical to their appearance and protection. However, issues like chalking, fading, blistering, peeling, and corrosion can compromise their quality.

Chalking:

Chalking occurs when the paint’s binder deteriorates due to prolonged exposure to UV light, resulting in a powdery residue on the surface. This is more common with low-quality paints and in outdoor applications where UV exposure is high.

Solution: Use high-quality UV-resistant paints and coatings. Regularly clean the surface to remove chalking residues and apply protective coatings as needed to extend the lifespan.

Fading:

Fading is caused by the breakdown of pigments due to UV radiation and weathering. It is more prominent in environments with intense sunlight.

Solution: Choose coatings with UV inhibitors and weather-resistant properties. Avoid using materials with color sensitivity in direct sunlight or harsh environments.

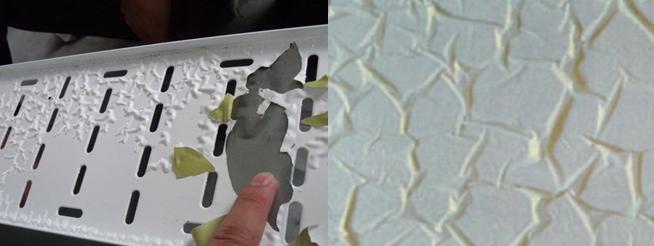

Blistering/Peeling:

These issues occur when moisture or contaminants get trapped under the coating or when surface preparation is inadequate. Poor application techniques can also contribute.

Solution: Ensure thorough cleaning and drying of the substrate before applying the coating. Use quality primers and follow proper coating application methods to enhance adhesion and minimize moisture infiltration.

Corrosion:

Corrosion develops when the protective coating is damaged, exposing the aluminum substrate to moisture and chemicals. This can happen due to scratches, environmental exposure, or improper maintenance.

Solution: Repair any coating damage promptly using touch-up paints or sealants. Regularly inspect the surface and apply anti-corrosion treatments to areas at risk of exposure.

Problem 2: Fabrication and Installation Issues

Fabrication and installation processes can also pose challenges that affect the structural and visual quality of pre-painted aluminum sheets. Below are the causes and solutions for common issues.

Scratches and Abrasions:

These are often caused during handling, cutting, or installation when protective measures are not taken. Sharp tools and improper storage can exacerbate the problem.

Solution: Use protective films on the sheets during handling and fabrication. Employ tools designed for aluminum and handle the sheets with care to minimize contact with abrasive surfaces.

Buckling and Distortion:

Improper handling, excessive force during installation, or inadequate support can lead to buckling or warping of the sheets.

Solution: Follow recommended guidelines for handling and installation. Ensure the sheets are properly supported and avoid applying uneven pressure during installation.

Seam Failures:

Seam failures often result from incorrect sealing methods or misalignment during installation. These gaps can allow moisture ingress, leading to corrosion and reduced durability.

Solution: Use high-quality sealants and ensure precise alignment during installation. Regularly inspect seams for integrity and repair any defects promptly.

Preventative Measures for Smooth Usage

To minimize issues with pre-painted aluminum sheets, adopting preventative measures during handling, fabrication, and installation is essential:

- Select high-quality materials: Choose pre-painted aluminum sheets from reputable manufacturers that use high-quality coatings with excellent durability, UV resistance, and corrosion resistance.

- Proper surface preparation: Ensure thorough cleaning and preparation of the aluminum surface before painting to ensure optimal adhesion and prevent coating defects.

- Careful handling and transportation: Use appropriate packaging and handling techniques to minimize the risk of scratches, abrasions, and other damage during transportation and storage.

- Proper fabrication and installation: Employ skilled professionals and follow best practices for fabrication and installation to avoid issues such as buckling, distortion, and seam failures.

- Regular inspection and maintenance: Conduct regular inspections to identify and address any potential issues early on. Implement a proactive maintenance program to repair any damage and ensure the long-term performance and appearance of the material.

Pre-painted aluminum sheets offer remarkable benefits but require careful handling to maintain their performance and aesthetics. By understanding and addressing common issues such as coating defects and fabrication challenges, you can enhance the longevity and functionality of these materials. Implementing preventative measures ensures smooth usage and preserves the value of investments in pre-painted aluminum sheets. With proper care, these versatile materials can deliver exceptional results across a wide range of applications.