As one of the core materials of electronic devices, electronic aluminum foil has always been the focus of electrical appliance manufacturers. As a term that doesn’t appear often, you may have doubts about it. What is electronic aluminum foil? What are the classifications of electronic aluminum foil? What are the applications of electronic aluminum foil? Don’t worry, you will understand electronic aluminum foil after reading this article. This reading will have a positive impact on your purchase of electronic aluminum foil.

What is Electronic Aluminum Foil?

Affected by the growth of market demand for new energy vehicles, there is a strong demand for aluminum foil for power batteries. Some aluminum foil manufacturers claim that the current aluminum foil processing fee has increased by 10% over the same period last year. Power batteries are a rapidly developing emerging field on the industrial chain and industrial development track. As the positive current collector of lithium-ion battery rechargeable batteries, benefiting from the acceleration of the global electrification of new energy vehicles, the price of electronic aluminum foil is also rising rapidly.

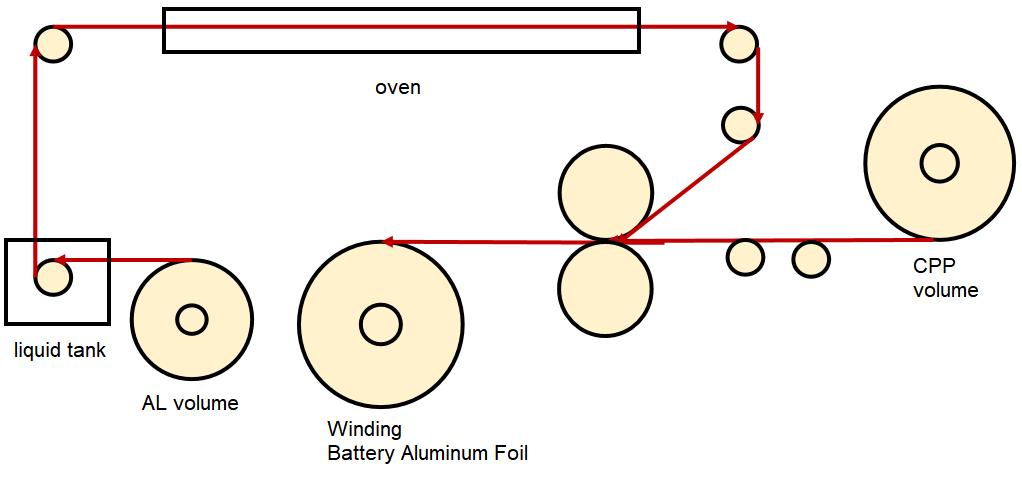

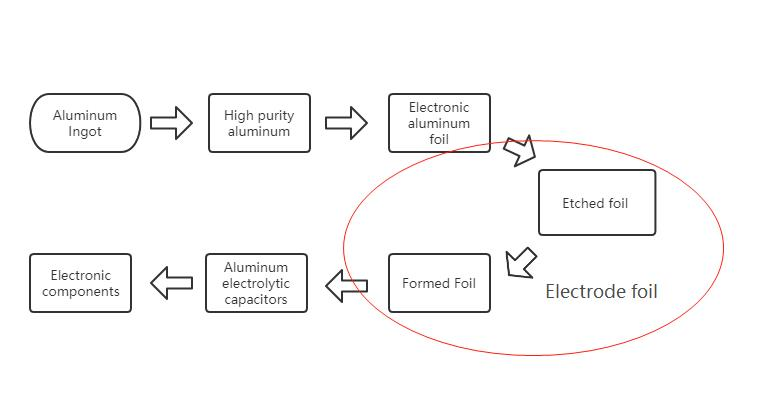

Electronic aluminum foil is processed from aluminum material into aluminum foil, and then subjected to surface corrosion treatment and oxidation treatment, and then winding processing, and finally made into a capacitor. Electronic aluminum foil is the key raw material for the production of aluminum electrolytic capacitors. Due to the order of the manufacturing process, it is divided into electronic aluminum foil and electrode foil. Electrode foil includes corrosion foil and activation foil.

Electronic aluminum foil is a kind of aluminum foil processed by a series of processes such as rolling, cleaning, and cutting of high-purity aluminum ingots. Electronic aluminum foil is the key raw material for the production of aluminum electrolytic capacitors.

How is Electronic Aluminum Foil made?

Electronic aluminum foil is a refined product made of high-purity aluminum foil. Hot-rolled refined aluminum (high-purity aluminum) into the aluminum plate, and then forged by cold rolling and annealing process. The production process of electronic aluminum foil includes casting-soaking-hot rolling-pre-annealing-cold rolling-intermediate annealing-cold rolling-foil rolling-slitting-performance testing-packaging.

| Raw material | Process 1 | Process 2 | Finished product | Application |

| Electronic Aluminum Foil | Corrosion Process | Increase the surface area of the aluminum foil | Corroded Foil | Aluminum Electrolytic Capacitors |

| Anode Aluminum Foil | ||||

| Electronic Aluminum Foil | Activation Process | Formation of oxide film | Activated Foil | Aluminum Electrolytic Capacitors |

| Anode Aluminum Foil |

How to Classify Electronic Aluminum Foil?

Electronic aluminum foil can be divided into high-pressure foil, low-voltage foil, and cathode foil. High-voltage anode foil can be divided into two categories, one is high-quality high-voltage anode foil; the other is ordinary high-voltage anode foil.

The high-quality high-pressure foil is characterized by high purity, high cubic texture, and thin surface oxide film. This type of product is of high quality but high cost. The aluminum purity is greater than 99.99%, the cubic texture is 96%, and the vacuum heat treatment conditions during the forging process are 10-3Pa~10-5Pa.

Ordinary high-pressure foil is an economical and practical high-pressure foil, with aluminum purity> 99.98%, cubic texture> 92%, and vacuum heat treatment is carried out under the conditions of 10-1pa~10-2pa.

Cathode foil can be divided into soft-state cathode foil and hard-state cathode foil. In Japan, cathode foil is usually forged by soft electrochemical corrosion, while in Western Europe, cathode foil is forged by hard chemical corrosion. Both have their advantages and disadvantages. The aluminum in the soft cathode foil is of high purity (>99.85%), and there is no copper, and the quality is high, but the cost is high; the hard cathode foil uses low-purity copper-containing aluminum foil, which is low in cost.

What are the Applications of Electronic Aluminum Foil?

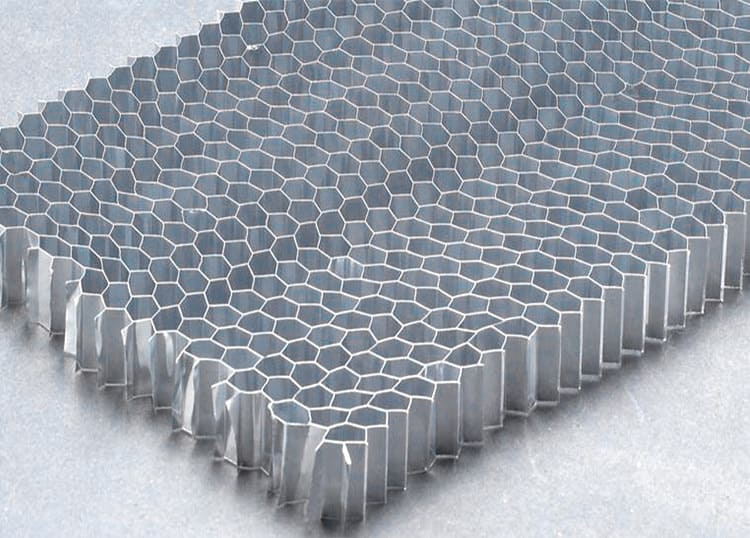

Electronic aluminum foil is often used in capacitors. According to different materials, capacitors can be divided into three categories: aluminum electrolytic capacitors, ceramic capacitors, and film capacitors. Among them, aluminum electrolytic capacitors are the most used variety among all electronic capacitor products.

Will the Price of Electronic Aluminum Foil Continue to Rise?

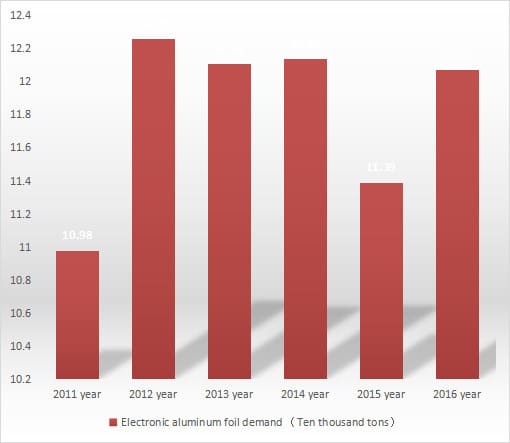

In China, the production capacity of electronic aluminum foil in 2016 was about 85,000 tons, an increase of 7,000 tons from 78,000 tons in 2015. The output of the electronic aluminum foil industry in 2016 was about 51,900 tons, an increase of 2.77% from 50,500 tons in 2015; In China, the market consumption of the electronic aluminum foil industry was about 47,900 tons, an increase of 3.01% from 46,500 tons in 2015. In 2016, the market size of the electronic aluminum foil industry was about 1.207 billion yuan, an increase of 5.97% from the 1.139 billion yuan in 2015.

Statistics of electronic aluminum foil demand in China from 2011 to 2016

With the continuous increase of aluminum raw materials and processing costs, the price of electronic aluminum foil is also soaring. At this time, more electronic aluminum foil suppliers will appear in the market. But among the many electronic aluminum foil suppliers or electronic aluminum foil manufacturers, the quality of the products they provide is uneven. Customers should choose good suppliers carefully. After all, no one wants to buy expensive and poor-quality electronic aluminum foil.

If you need to buy electronic aluminum foil, I would like to recommend CHAL electronic aluminum foil to you at the end of the article. As a professional electronic aluminum foil supplier, they have been providing high-quality, cost-effective electronic aluminum foil to global customers. If you need to know the products and quotations of CHAL electronic aluminum foil, you can contact the sales staff of CHAL.