If you are reading this article, you may want to know the characteristics of the aluminium tube and whether it meets your needs. This article will show the contents of the aluminium tube from multiple aspects, possibly some of you are known. This article will describe this content in more detailed, and popularize more knowledge about aluminium tubes.

1. What is aluminium tube?

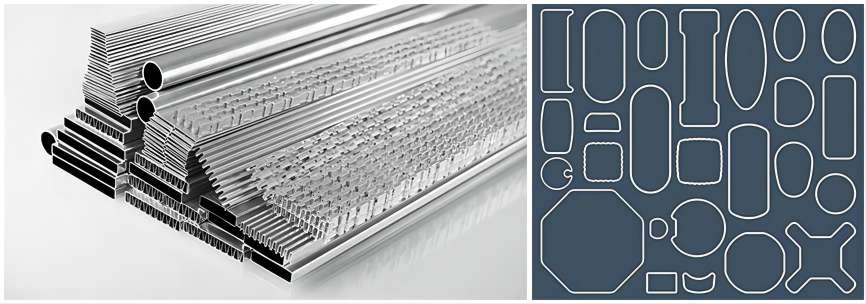

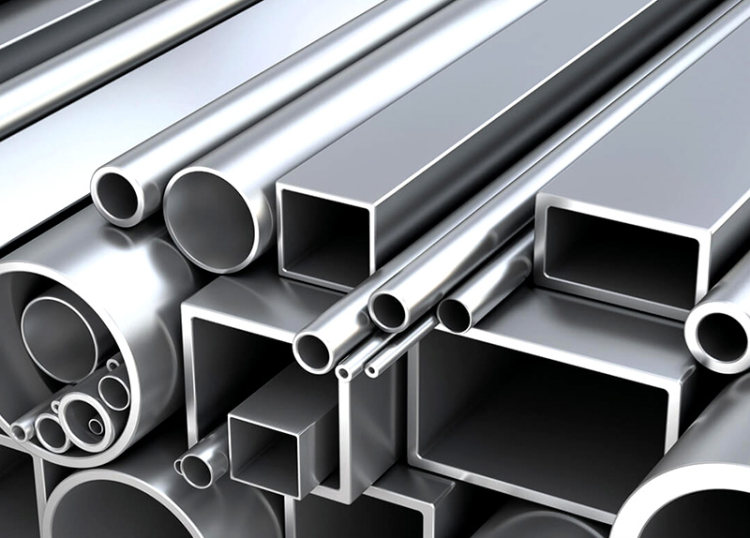

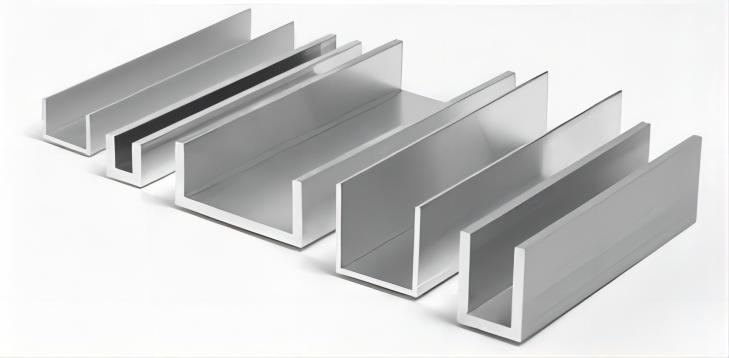

Usually, the aluminium tube refers to a hollow pipe made of pure aluminium or aluminium alloy. And the aluminium tube shape is determined by its outer diameter and wall thickness. There is circular, rectangular, square or elliptical, in inches or millimetres distinguish. Aluminium pipes have extensive in the field of aerospace and commercial manufacturing, including healthcare products, entertainment products, and machine parts. The weight of aluminium is one-third of steel, and the manufacturer welcomes aluminium due to its durability. The aluminium tube can be effectively applied to multiple fields due to various features, such as intensity and flexibility.

2. What are the characteristics of the aluminium tube?

Lightweight

Due to the lightweight of the aluminium tube, the aluminium tube per unit of weight is more than the steel pipe. Many products benefit from products that use lighter pipes, especially those that require a certain degree of activity, such as wheelchairs and outdoor furniture.

Heavy Corrosion Resistance

The aluminium tube is more difficult to lose gloss than other metal tubes. It is easier to apply to the decoration of paints and other decorations, thereby enhancing its aesthetic attraction.

High thermal conductivity

Aluminium has excellent thermal conductivity, making the aluminium tube an ideal choice for relying on temperature control product(including refrigerators, solar and air conditioning systems). And the lightweight and durability of aluminium pipes benefits the hydraulic system, fuel line, framework and rack.

Workability

The toughness of the aluminium tube is very strong, which can be processed into any available shape. So it is often used as a connecting tool.

3. Type of aluminium tube

Aluminium has several different alloys. Aluminium mix with magnesium and silicon have a solid alloy. It also means that different alloy combinations can form different aluminium tube types. Their functions are different. For example, manufacturers often use aluminium squares alloys 6061 for many medium and high-intensity applications because it increases weldability and excellent corrosion resistance. 6061 Aluminium tube is also easy to anode oxidation, which makes it very suitable for heat treatment. It is also the cheapest aluminium tube alloy.

The manufacturer also uses aluminium alloy tube 6063 to achieve an extremely smooth surface finish. Since the aluminium alloy 6063 has only half of the aluminium alloy 6061, it often appears in valued rather than intensity applications. This material still has many anodized capacities as the aluminium alloy 6061.

When using metal parts in manufacturing and construction, heating strength is often a key factor. A metal tube is no exception. In most cases, the two manufacturing tasks required for aluminium tubes are bending and joining.

For the bending tube, consider three main factors:

Moldable

Certain aluminium alloys, such as 3xxx, 5xxx, and 6xxx series, have higher formability than other aluminium alloys, making it a good material that is curved. Typically, a higher intensive alloy also has a lower strength.

Thickness and bending radius

Aluminium is like other metals, “processing harden” during the bending process, which means aluminium will become more and more robust when formed. However, if the radius is too small in the thickness of the tube, the material is excessively machined, more likely to fail.

Extendability

The elongation percentage is a way to describe the difference between metal yield strength and its limit tensile strength. Yield strength is a point that aluminium alloy can be bent and no longer restore its original shape. On the other hand, the tensile strength is the maximum stress that can be applied to aluminium before aluminium cracking. The larger the difference between these strengths, the higher the formability of the alloy.

The connecting tube typically means that a tube is connected to another tube, or one end is connected to some type of container. Most commercially produced pipes can be designed for specific types, shapes and sizes of connections.

The above example is for considering the need for bending and connected aluminium tubes. If the aluminium tube function you need is just bending and connection, you can directly refer to the above recommendations. The type of aluminium tube is very rich, and other types of aluminium tubes need to be analyzed for industry characteristics. For more aluminium tube information, you can get the answer by contacting us.

4. What is the use of aluminium tube?

Aluminium is applied to various industries because of its low density and through the passivation process. Because when metal parts are used in manufacturing and construction, the heating strength is often a key factor. The metal tube is no exception. Top-tensive strength refers to a dual fusion that requires flexibility and intensity, and the aluminium tube can achieve this application. The aluminium tube is lightweight, so the volume per unit weight of the aluminium pipe is more than the steel. Many products are more inclined to use lighter pipes, especially those who need mobility, such as wheelchairs and outdoor furniture. In addition, aluminium tubes are also ideal for use in the following industries or product types:

Heat exchanger

The aluminium tube is a strong thermal conductor. The 1000 series of aluminium alloy is the best choice compared to similar conductors. Usually, The tube is a carrier that transferring heat from one place to another. The following products are available in the field of heat exchanger:

- Engine

- Refrigerator

- Air conditioning and heating system

- Ventilation

- Solar energy

- Steam generator

- Reboiler

Transportation (including aerospace)

The versatility of aluminium tubes is very suitable for vehicles such as automotive, aerospace and rail transportation. As they need a strong but light material assembly to assist completion. This includes:

- Car body

- Railing

- Journey

- Fuel pipe

- Hydraulic system

- Frame

Frame structure or public utilities

You may see a lot of billboards, road sign, etc., on the highway and include the guardrails and other signs. Most of these facilities are made of aluminium tubes from corrosion resistance and low maintenance costs. Other public applications using aluminium tubes also include:

- Building Decoration

- Fencing

- Outdoor structure

- Framework and support

Frame structure or public utilities

You may see a lot of billboards, road sign, etc., on the highway and include the guardrails and other signs. Most of these facilities are made of aluminium tubes from corrosion resistance and low maintenance costs. Other public applications using aluminium tubes also include:

- Building Decoration

- Fencing

- Outdoor structure

- Framework and support

5. Aluminum tube VS other metal pipes

Many industries must use metal tubes, and now more and more industries also use aluminium tubes instead of other traditional metal tubes. What is the difference between the aluminium tube and other metal tubes are? What are their respective advantages? Seeing the following analysis, I believe you can choose the suitable pipe according to your own industry needs.

Aluminium tube has the following advantages compared to other hard metal tubes (such as copper and stainless steel):

Material lightweight: There is a big advantage in the fields of ships, aerospace and other fields;

Strong toughness: as high plasticity of the connection material;

Heavy corrosion resistance: longer service life, more cost-effective;

The surface is smooth, it is not easy to rust: strong decoration performance, low maintenance cost;

Heavy thermal conductivity: The aluminium itself has strong thermal conductivity, which can achieve the same performance as other materials being processed.

The disadvantage of aluminium tubes are:

Heating will deform: Ordinary aluminium tubes that are heated to a certain extent will deform. Therefore, aluminium processing is generally carried out according to the use of aluminium tubes, which is not easily deformed;

Material lightweight: Some hard metals will be more advantageous in some areas that require quality strength;

Price cost: The price cost of aluminium can be high than other metals. Because the weight of aluminium is lighter than other metals, and 1 pound aluminium is much more than 1 pound of other metals.

More about aluminium tubes and other metals, you can view this article:

Difference Between Aluminium Tube and Steel Tube

In summary, the main factor to consider when choosing the most suitable tube for your application is the characteristics of the application environment, such as whether it takes corrosion resistance, whether it takes later maintenance, whether to conduct conductive heat transfer is required. Once the metal category that best suits your application is selected, you can choose the necessary metal series and alloy processing.

6. Precautions

Aluminium must be mixed with other metals

In order to make aluminium to be acceptable building materials – which means that aluminium products require greater load-bearing capacity – it needs to be mixed with other metals. When mixed in an appropriate ratio, the strength of aluminium can actually be equal to the strength of the steel without sacrificing its weight advantage. Engineers often use aluminium alloys in components that require low or high corrosion resistance.

Aluminium can’t be heated

If you don’t need the conductivity of the aluminium tube, do not heat the aluminium tube. As mentioned earlier, low temperature will enhance the toughness of the aluminium tube. Conversely, heating will affect the performance of aluminium.

Rough things in aluminium

Aluminium will be diluted (or corrosion) in high stress or high corrosive environments. More durable metals in aluminium will be revealed. This can also be understood to refine ore compositions.

The inner surface and outer surface of the metal tube should be coated and finishing. However, it requires a specific surface treatment process, for example:

- Galvanized – the tube has galvanized layers to improve corrosion resistance.

- Shining surface – secondary polishing should make the pipe look bright.

- Plating-tube will apply another thin metal coating to enhance its external physical properties such as conductivity and corrosion resistance.

- Painting – the tube will have a powder coating for identifying and corrosion resistance.

Before purchasing metals, you need to pay attention to the above matters, and the aluminium tube can be maximized during the operation.

7. Get Suitable Prices of Aluminium Tubes

In general, the price of the aluminium tube on the market is determined by the series of aluminium tube. It is divided into 1-9 series aluminium tube, the higher the coefficient, the higher the price of an aluminium tube. Because of the difference in precision and use, various series of aluminium Tube needs and other metallic mixing alloys. The following are the various series of aluminium tubes and recommended alloys provided by CHAL

Options of aluminum alloy

| Aluminum Series | Alloy Grade | CHAL Usage Ratio | Recommendation |

| 1XXX | 1050/1060/1100/1197 | 10% | Pure aluminum, Main component Al≥99% |

| 2XXX | 2011/2017/2024 | 2% | Copper- Aluminum Alloy |

| 3XXX | 3003/3103/3A03/3A21 | 15% | Manganese -Aluminum Alloy |

| 4XXX | 3% | Silicon-Aluminum Alloy | |

| 5XXX | 5049/5052/5083/5086 | 7% | Magnesium-Aluminum Alloy |

| 6XXX | 6005A/6061/6063 | 52% | Magnesium Silicon-Aluminum Alloy |

| 7XXX | 7075 | 7% | Zinc-Aluminum Alloy |

| 9XXX | 9A66/9A52 | 4% | Customized alloy |

The price of the aluminium tube is based on the specific needs of the product. Large producers usually need to customize aluminium tubes, length, size, wall thickness, aluminium, etc., which need to be considered in pricing. There are hundreds of hundreds of aluminium tubes in different precision, and the price is also not uniform.

The only thing you can do is on which aspect of the aluminium tube you need. You can find a trusted aluminium tube supplier give you professional suggestion, or you propose your specific aluminium tube specifications and quantity of CHAL Aluminium Corporation. We will help your manufacturer produce the best and more cost-effective products that you can imagine.

8. Conclusion

All of the above is the description of aluminium tubes, and you should be able to think about what kind of materials you need for your manufacturer.

In short, the first thing to consider when choosing a metal tube is what industry you need to use, what special properties are needed in this industry. Lightweight, strong electrical conductivity, strong corrosion-resistance, high toughness, low maintenance cost, strong plasticity, is the performance of aluminium tubes. You also need to note that the aluminium tube will affect its toughness after heating. Generally, if used outdoors, it will rarely be heated to the point where it affects its performance.

If you have already determined that the aluminium tube meets your needs, and hope to find a trusted aluminium tube supplier as soon as possible. Please visit the CHAL website or contact our sales staff. CHAL is committed to providing customers with the best quality aluminium products and meets the key criteria for the market. We offer complete aluminium product manufacturing, processing, packaging, assembly, and logistics, and after-sales service and support.