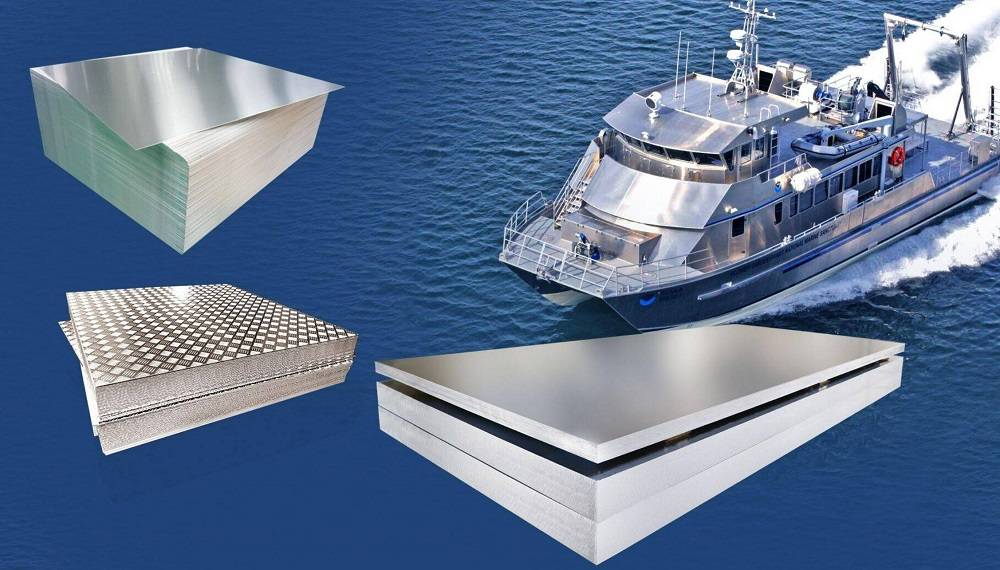

If you don’t touch it, the appearance of an aluminum plate and stainless steel plate looks similar, but in fact, the two are completely different metal materials. Due to their different hardness, alloy types, etc., they are used in completely different fields. So what is the difference between aluminum plates and stainless steel plates?

The strength-to-weight ratio of aluminum plate and stainless steel plate is different

1. Degree to weight ratio. The strength of the aluminum plate is usually not as good as that of the stainless steel plate, and it is only about one-third of the stainless steel plate under the same conditions. This is also the main reason why aircraft are dominated by aluminum sheets.

2. Corrosion performance is different. Stainless steel plate is composed of iron, chromium, nickel, manganese, copper, and other elements. Adding chromium elements can provide good corrosion resistance. Also, since it is non-porous, the corrosion resistance of the stainless steel material is improved.

Aluminum sheets have high oxidation and corrosion resistance, mainly because of their passivation layer. After the aluminum plate is oxidized, its surface will also turn white. But in some extremely acidic or alkaline environments, aluminum can corrode rapidly, with catastrophic consequences.

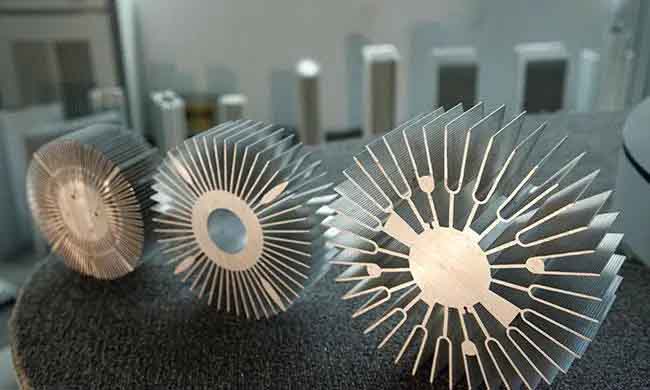

3. In terms of thermal conductivity, the thermal conductivity (thermal conductor) of aluminum plates is better than that of stainless steel plates. This is also one of the main reasons why aluminum panels are often used in automotive radiators and air conditioning units.

4. In terms of cost, the aluminum plate is usually cheaper than the stainless steel plate.

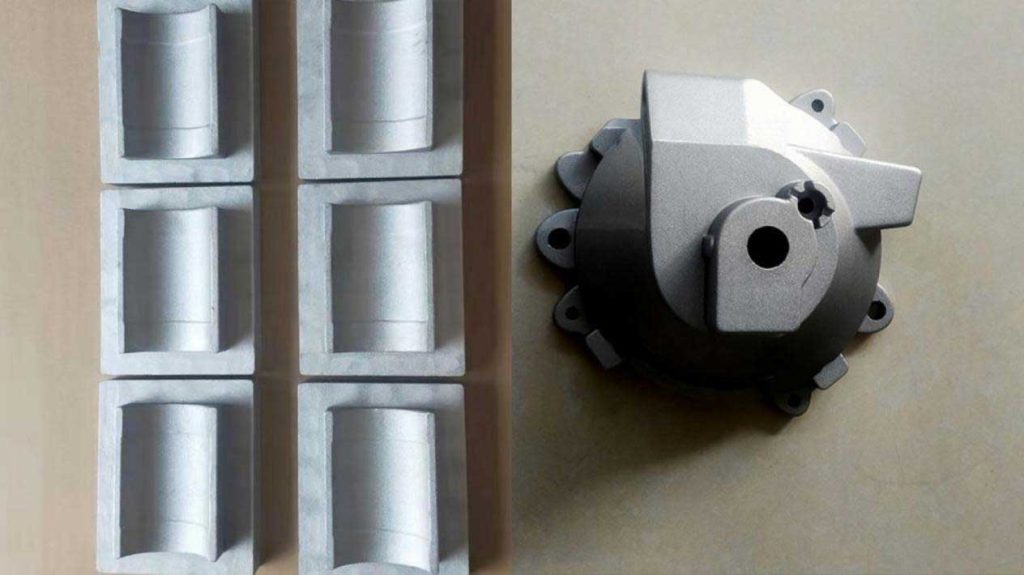

5. In terms of usability, there are also differences between aluminum plates and stainless steel plates. The aluminum sheet is quite soft and easy to cut and shape. And because of its high wear resistance, stainless steel can be difficult to use, and stainless steel is also harder than aluminum, making it more difficult to form.

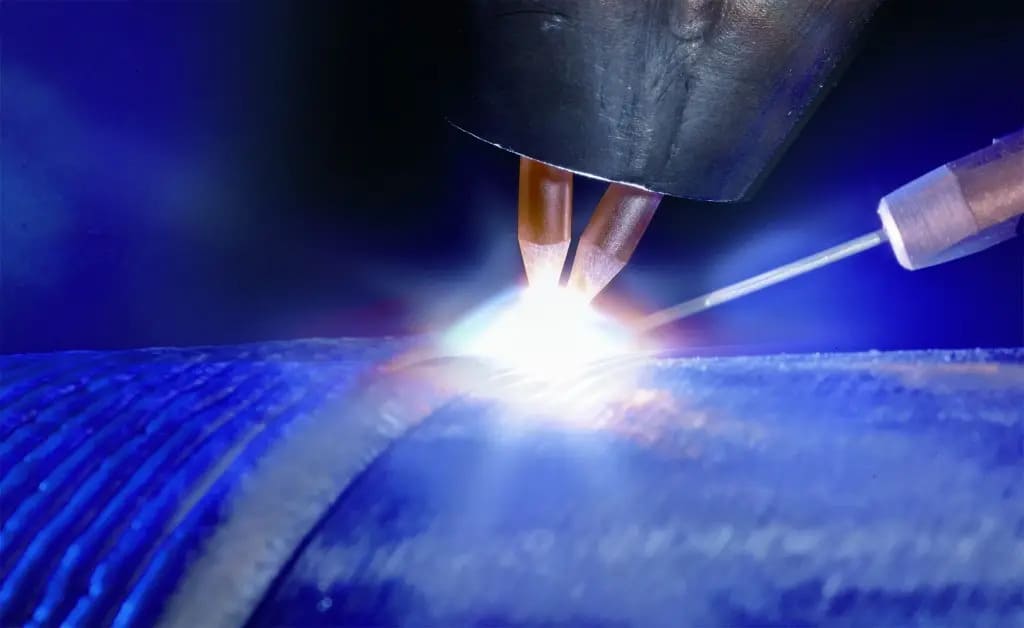

6. In terms of weldability, stainless steel plates are relatively easy to weld, while aluminum welding is more difficult.

7. In terms of heat resistance, the maximum operating temperature of stainless steel sheets is much higher than that of aluminum sheets. Usually, aluminum sheets become very soft when they are above about 400°C.

8. Electrical conductivity. Compared with most metals, the electrical conductivity of stainless steel plates is very poor. And the aluminum plate is a very good power material. High-voltage overhead power lines are usually made of aluminum because of their high electrical conductivity, lightweight, and corrosion resistance.

9. In terms of strength, if the weight factor is not considered, the stainless steel plate is stronger than the aluminum plate.

What if you don’t know whether to choose aluminum or stainless steel?

If you have doubts about choosing an aluminum plate or stainless steel plate as your product material, you may directly ask the aluminum plate manufacturer or the stainless steel plate manufacturer. As a professional material manufacturer, they are sure to recommend you the right plate for your product.

Of course, if you decide to use an aluminum sheet as the raw material for your product, then a CHAL aluminum plate will be your best choice. CHAL is a professional aluminum plate manufacturer. Their aluminum plates have passed various performance tests perfectly, and the price is beyond your imagination. If you have any questions, please send an email or call the CHAL engineers directly, and they will give you an accurate reply.