Wheels are an integral component of the modern automobile, and over the years, their construction materials have seen a significant evolution. Steel and aluminum are two of the most commonly used materials for wheel production, and each has its own set of advantages and disadvantages. The choice between steel and aluminum wheels depends on various factors, including strength, weight, cost, and aesthetics. In this article, we will delve into the evolution of wheel materials, comparing the merits and drawbacks of steel and aluminum wheels.

Steel Wheels: The Sturdy Workhorses

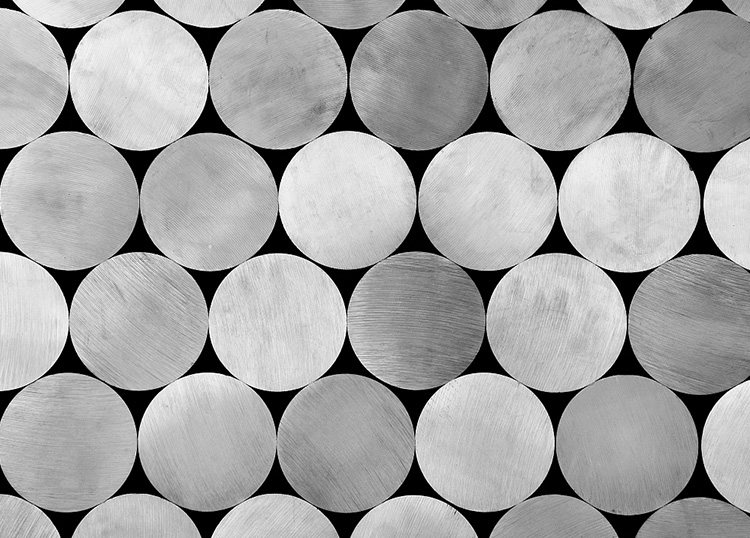

Steel wheels have been a staple in the automotive industry for many years, dating back to the early days of the automobile. These wheels are typically constructed from various grades of steel, with some of the most common being mild steel and high-strength alloy steel. While steel wheels have served well over the decades, their advantages and disadvantages are worth exploring.

Advantages of Steel Wheels:

- Durability: Steel wheels are renowned for their robustness. They can withstand harsh conditions, making them a preferred choice for heavy-duty vehicles like trucks and industrial machinery.

- Cost-Effective: Steel is a cost-effective material, making steel wheels more affordable for vehicle manufacturers and consumers. This affordability has contributed to their enduring popularity in the market.

- Low Maintenance: Steel wheels are relatively low maintenance. They are resistant to corrosion and are easy to repair if damaged.

Disadvantages of Steel Wheels:

- Weight: One of the significant drawbacks of steel wheels is their weight. Steel is denser than aluminum, resulting in heavier wheels. This added weight can lead to reduced fuel efficiency and increased wear and tear on other vehicle components.

- Aesthetics: Steel wheels are often considered less attractive than their aluminum counterparts. Their utilitarian appearance may not appeal to those looking for a more stylish and modern design.

Aluminum Wheels: The Lightweight Innovators

The advent of aluminum wheels introduced a new era in wheel design and construction.

Aluminum wheels used in automobiles are typically made from a specific type of aluminum alloy and are produced through casting or forging processes. The specific type of aluminum alloy used in these wheels can vary among manufacturers, but it is generally a type of aluminum that offers a good balance of strength, weight savings, and corrosion resistance. It is not in its pure elemental form, which is not suitable for structural applications due to its relatively low strength.

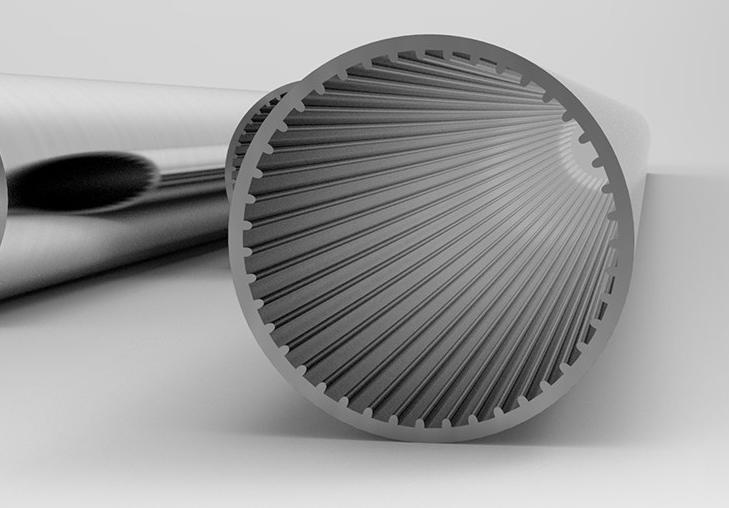

The most common aluminum alloy used for wheels falls within the 6000 series, such as 6061 or 6063 aluminum alloy. These alloys are known for their combination of strength, formability, and corrosion resistance. Cast aluminum wheels are made by pouring molten aluminum alloy into a mold, while forged wheels are created by subjecting a solid aluminum billet to extreme heat and pressure, which causes the aluminum to take on the desired wheel shape. Aluminum wheels have become increasingly popular in the automotive industry for various reasons.

Advantages of Aluminum Wheels:

- Lightweight: The most prominent advantage of aluminum wheels is their significantly lighter weight compared to steel wheels. This weight reduction enhances vehicle performance, including acceleration, braking, and fuel efficiency.

- Aesthetic Appeal: Aluminum wheels are often more visually appealing. Their sleek and modern designs are a popular choice for those who want to enhance the overall look of their vehicles.

- Heat Dissipation: Aluminum’s superior thermal conductivity allows for better heat dissipation, which can be especially beneficial for high-performance vehicles, as it helps prevent brake fade.

Disadvantages of Aluminum Wheels:

- Cost: Aluminum wheels are typically more expensive to manufacture than steel wheels. This cost is often passed on to consumers, making vehicles equipped with aluminum wheels pricier.

- Susceptibility to Damage: While aluminum wheels are durable, they are more susceptible to damage from road hazards and impacts. Potholes and curbs can easily cause dents or cracks in aluminum wheels.

- Maintenance: Aluminum wheels require more care to maintain their appearance. They are more prone to corrosion and oxidation, necessitating regular cleaning and protective coatings.

The Ongoing Debate

The choice between steel and aluminum wheels ultimately depends on the intended use, budget, and personal preferences of the vehicle owner. Steel wheels remain a practical choice for utilitarian and heavy-duty applications, offering durability and cost-effectiveness. On the other hand, aluminum wheels shine in terms of aesthetics and performance, making them an ideal option for those who want to enhance their vehicle’s appearance and driving dynamics.

In recent years, advancements in alloy composition and wheel manufacturing techniques have bridged some of the gaps between steel and aluminum wheels. These developments have led to lightweight and durable aluminum wheels and more cost-effective steel alternatives.

As technology continues to progress, the evolution of wheel materials is far from over. Emerging materials, such as carbon fiber composites, are being explored for their potential to combine the best attributes of both steel and aluminum while addressing their respective weaknesses. The automotive industry’s ongoing pursuit of the perfect wheel material underscores the importance of innovation in creating safer, more efficient, and stylish vehicles for the future.